Rotary clamping type shin support and shin pad assembled structure for total knee replacement and implementation method thereof

A technology of total knee replacement and assembly structure, applied in the direction of skull, knee joint, bone implants, etc., can solve the problem of unsuitable tibial tray and tibial spacer, and achieve the effect of improving life expectancy and shortening the learning curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

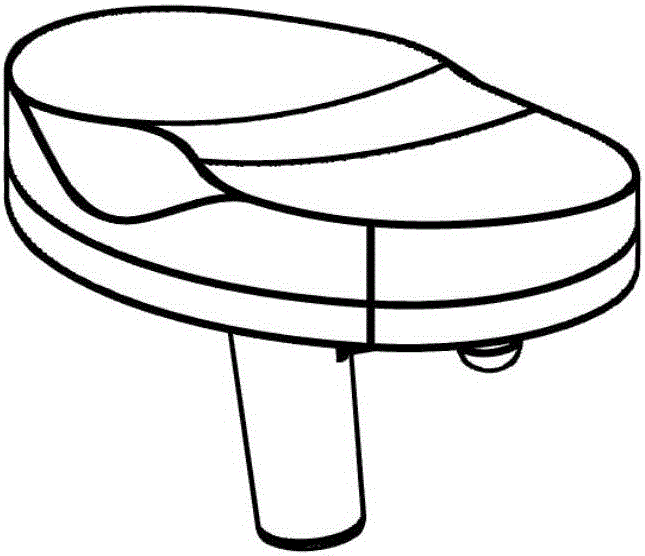

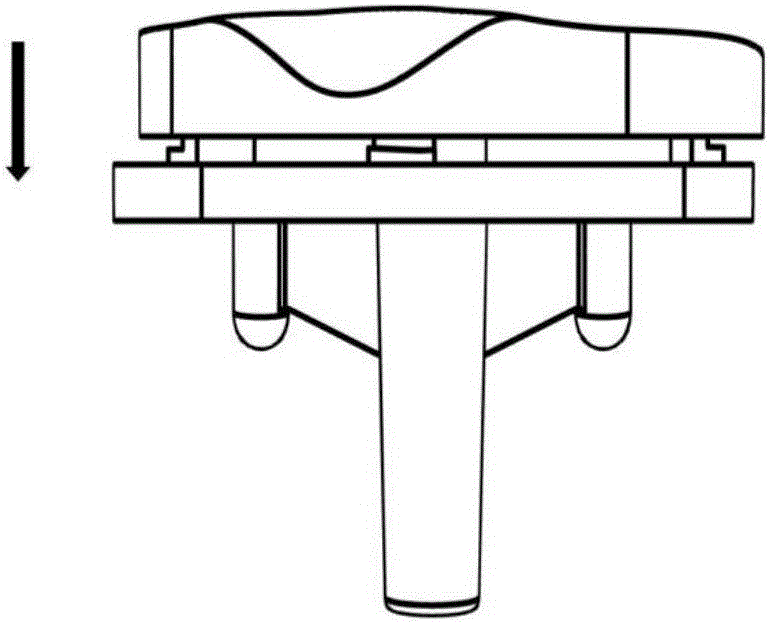

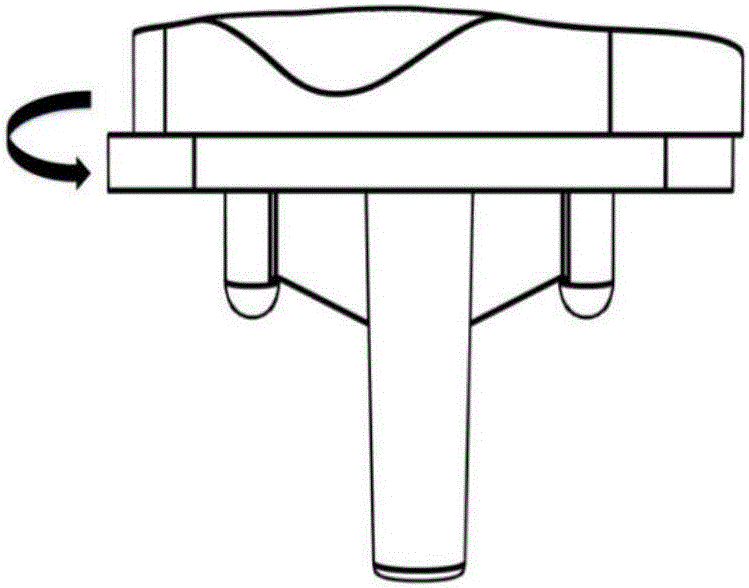

[0047] like figure 1 , Figure 3(a)-Figure 3(c) and Figure 4(a)-Figure 4(c) As shown, the assembly structure of the rotating clamping type total knee replacement tibial support and tibial spacer in this embodiment has:

[0048] 1) There is a fixed cylinder 1 on the lower surface of the tibial spacer (that is, the contact surface with the tibial tray);

[0049] 2) On the lower surface of the tibial spacer (that is, the contact surface with the tibial tray), there are three arc bodies 2 with a locking mechanism, and the three arc bodies 2 are respectively located in the front of the tibial spacer and in the left and right directions;

[0050] 3), there is a fixed circular groove 3 on the upper surface of the tibial support (that is, the contact surface with the tibial spacer);

[0051] 4) On the upper surface of the tibial support (that is, the contact surface with the tibial spacer), there are three circular arc grooves 4 with a locking mechanism, and the three circular arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com