Biological corn feed and production technology thereof

A technology of corn feed and production process, which is applied in the direction of animal feed, animal feed, molding or processing of animal feed, etc., to achieve the effects of ensuring health, fast absorption, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A biological corn feed is composed of the following raw materials in parts by weight: 53.75 parts of corn, 26 parts of soybean cake, 5 parts of meat and bone meal, 14 parts of flax cake, 0.25 part of table salt, 0.2 part of stone powder, 0.8 parts of methionine and oil.

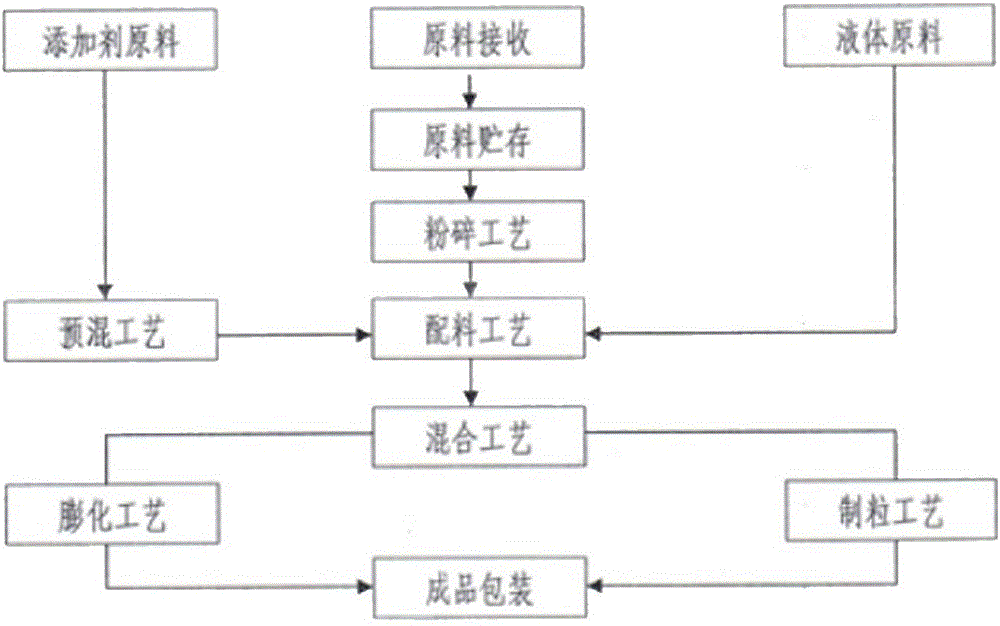

[0030] Such as figure 1 Shown, the production technology of described biological corn feed comprises the steps:

[0031] 1) The raw materials corn, soybean cake, meat and bone meal, and flax cake are cleaned and sieved by receiving equipment to remove impurities, magnetically separated in a magnetic separator to remove magnetic impurities, and then transported to the raw material warehouse for storage;

[0032] 2) Pulverize the stored raw materials to a qualified particle size through a pulverizer, weigh each raw material through a batching scale according to a certain proportion, and carry out batching in a mixer, and mix evenly;

[0033] 3) During the mixing process, the solid finished product of mi...

Embodiment 2

[0036] A biological corn feed is composed of the following raw materials in parts by weight: 50.5 parts of corn, 24 parts of soybean cake, 8.25 parts of meat and bone meal, 15.75 parts of flax cake, 0.5 part of table salt, 0.4 part of stone powder, 0.6 parts of methionine and oil.

[0037] Such as figure 1 Shown, the production technology of described biological corn feed comprises the steps:

[0038] 1) The raw materials corn, soybean cake, meat and bone meal, and flax cake are cleaned and sieved by receiving equipment to remove impurities, magnetically separated in a magnetic separator to remove magnetic impurities, and then transported to the raw material warehouse for storage;

[0039] 2) Pulverize the stored raw materials to a qualified particle size through a pulverizer, weigh each raw material through a batching scale according to a certain proportion, and carry out batching in a mixer, and mix evenly;

[0040] 3) During the mixing process, the solid finished product o...

Embodiment 3

[0043] A biological corn feed is composed of the following raw materials in parts by weight: 45 parts of corn, 30 parts of soybean cake, 8.5 parts of meat and bone meal, 15 parts of flax cake, 0.5 part of table salt, 0.5 part of stone powder, 0.5 parts of methionine and oil.

[0044] Such as figure 1 Shown, the production technology of described biological corn feed comprises the steps:

[0045] 1) The raw materials corn, soybean cake, meat and bone meal, and flax cake are cleaned and sieved by receiving equipment to remove impurities, magnetically separated in a magnetic separator to remove magnetic impurities, and then transported to the raw material warehouse for storage;

[0046] 2) Pulverize the stored raw materials to a qualified particle size through a pulverizer, weigh each raw material through a batching scale according to a certain proportion, and carry out batching in a mixer, and mix evenly;

[0047]3) During the mixing process, the solid finished product of micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com