Complementary dead-zone driving circuit of T-type three-level IGBT

A drive circuit, three-level technology, applied to electrical components, output power conversion devices, AC power input conversion to DC power output, etc., can solve the problems of increasing manufacturing costs, increasing dead time, etc., to achieve electrical isolation , save DSP resources, and avoid the effect of IGBT short-circuit failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

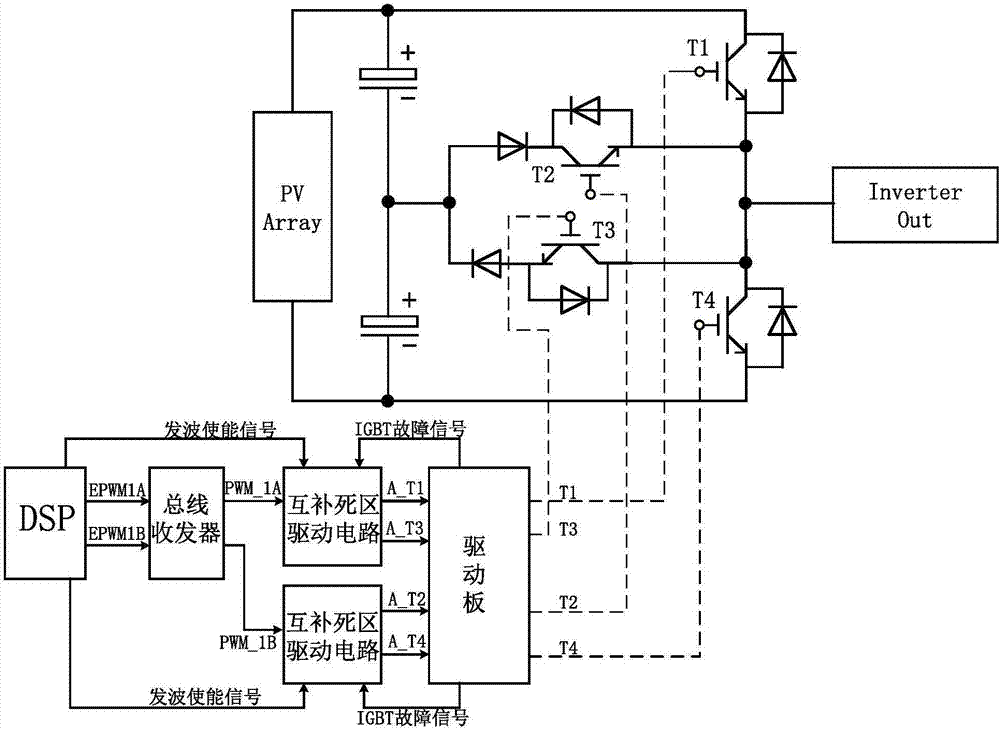

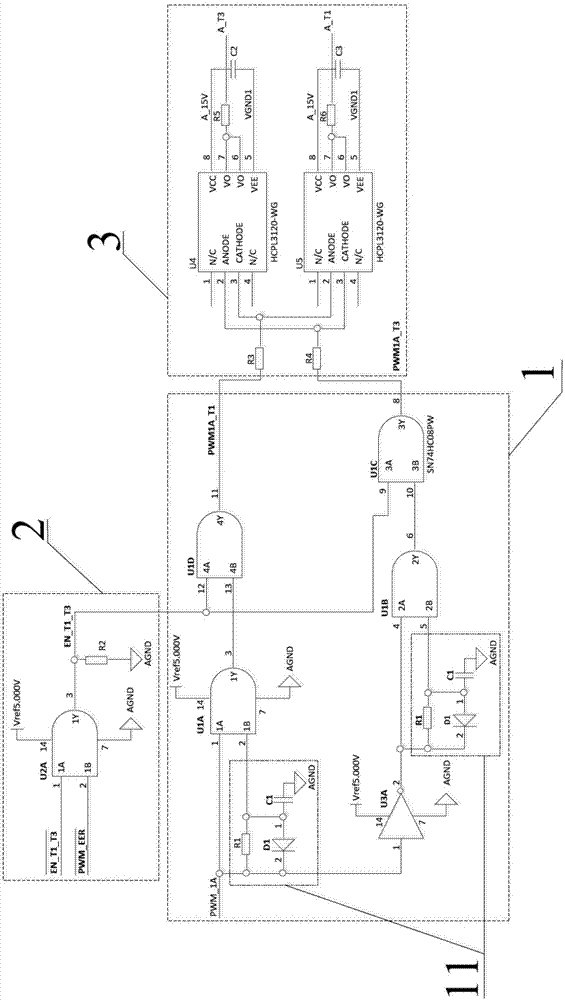

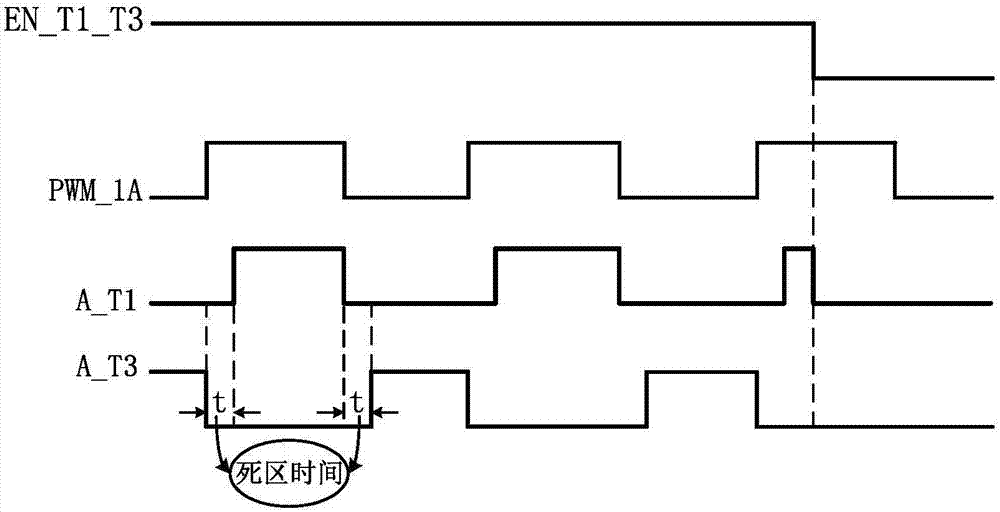

[0022] The overall control principle block diagram of this embodiment is as follows figure 1 As shown, the DSP chip sends out two driving signals of EPWM1A and EPWM1B, and outputs PWM_1A and PWM_1B after the level conversion of the bus transceiver; the driving signal of PWM_1A passes through the complementary dead-time driving circuit, and outputs two complementary driving signals with dead time A_T1 and A_T3; PWM_1B driving signals pass through the complementary dead-time driving circuit, and output two complementary and dead-time driving signals A_T2 and A_T4; A_T1, A_T2, A_T3 and A_T4, four driving signals, directly drive T through the driver b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com