Processing device for half-shaft hardening machine tools

A technology for quenching machine tools and processing devices, applied in the field of mechanical processing, can solve problems such as affecting production efficiency, affecting the appearance of workpieces, and high labor intensity, and achieves the effects of accelerating processing efficiency, avoiding uneven cooling, and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

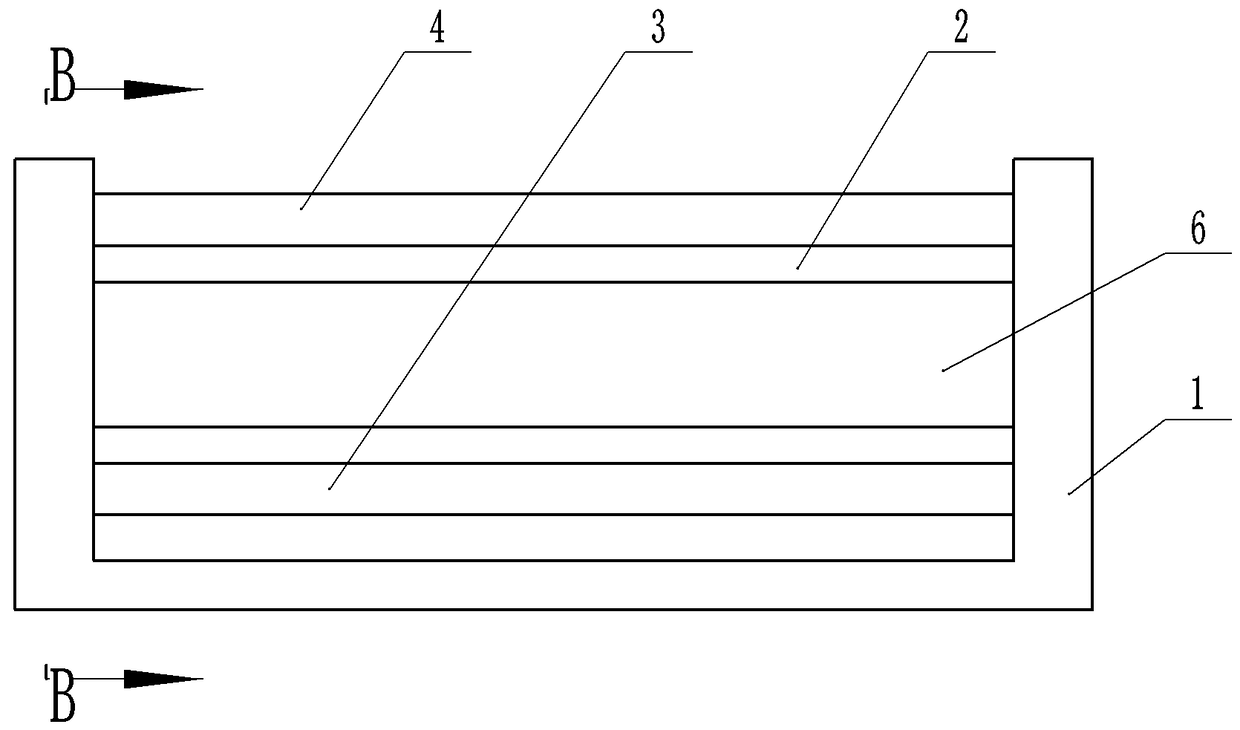

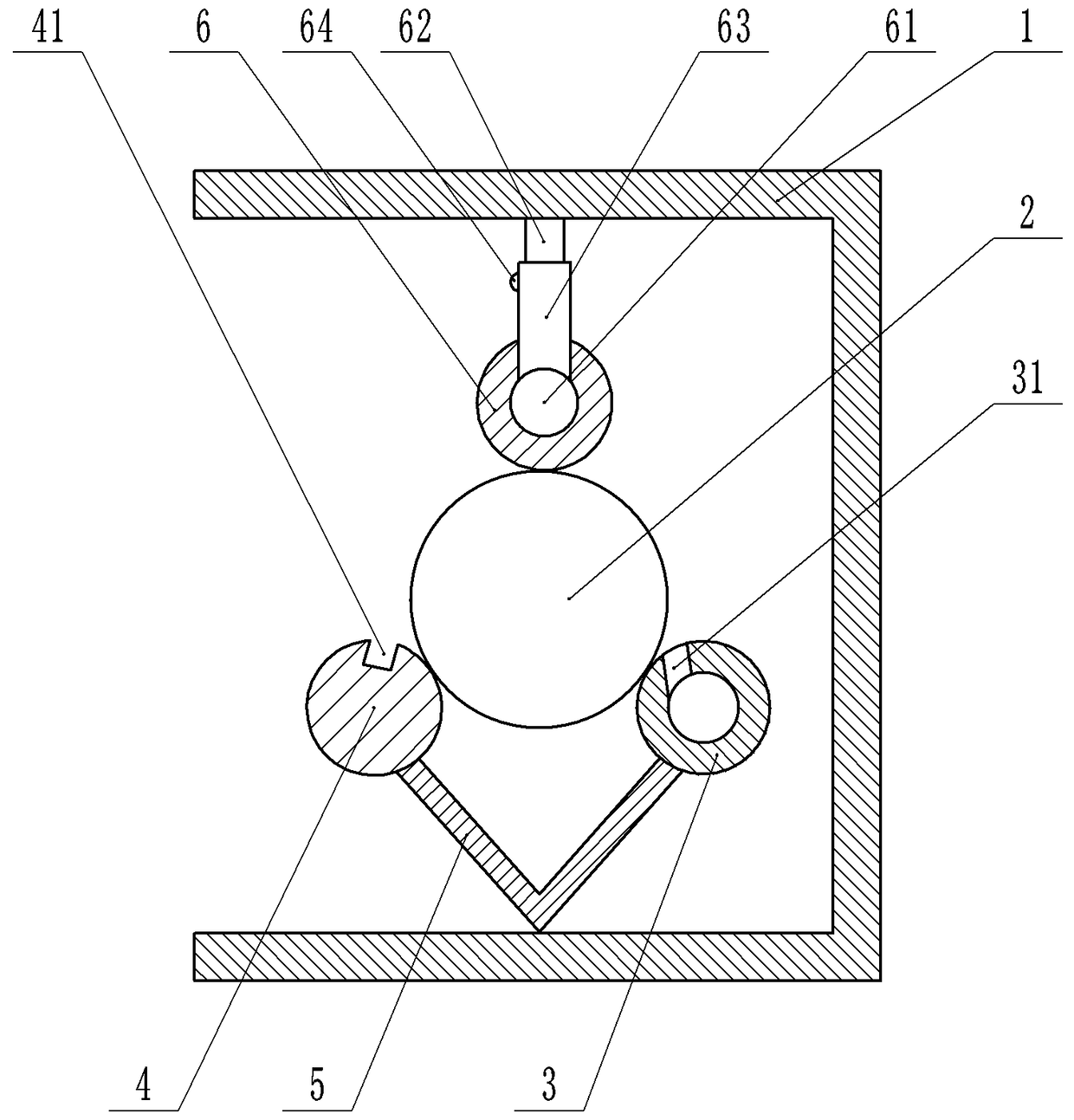

[0021] The reference signs in the accompanying drawings of the description include: fixed frame 1, half shaft 2, water spray pipe 3, water outlet hole 31, threaded roller 4, groove 41, V-shaped plate 5, pressure roller 6, rotating shaft 61, inner rod 62 , outer rod 63, raised button 64.

[0022] Such as figure 1 , figure 2 As shown, the processing device for half-axis quenching machine tools includes a fixed frame 1 made of bakelite, a V-shaped plate 5, a pressure roller 6, a first motor, a second motor and two telescopic rods, and the telescopic rods are fixed on The upper part of the fixed frame 1. The telescoping rod comprises an inner rod 62 and an outer rod 63, the outer rod 63 is slidably connected on the inner rod 62, the surface of the inner rod 62 is provided with a raised button 64, and the surface of the outer rod 63 has a plurality of buttons 64 which can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com