High-strength mildew-proof wall hanging plate and method for processing same

A processing method and high-strength technology, which is applied in the field of high-strength mildew-proof wall hanging board and its processing, can solve the problems of endangering the health of residents, more chemical pollution in new homes, poor strength and bending performance of wall hanging boards, and unfavorable processing and use of wall hanging boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

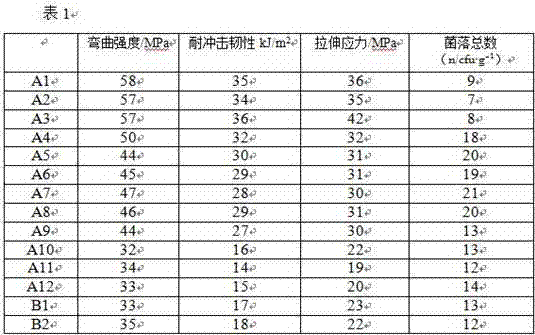

Examples

Embodiment 1

[0056] 1) First mix polyvinyl chloride resin (weight-average molecular weight of 20,000), polypropylene resin (weight-average molecular weight of 30,000), polycarbonate, dibutyl phthalate, ethyl acetate and KH550 silane After the coupling agent is mixed, it is heat-treated at 170°C for 4 hours to obtain the mixture M1;

[0057] 2) Add the reinforcing filler W1 to the mixture M1, and heat-treat at 185°C for 2 hours to prepare the mixture M2;

[0058] 3) The mixture M2 was compression-molded and processed at 185° C. to obtain the high-strength mildew-proof wall-hanging board; denoted as A1.

[0059] Among them, the dosage ratio of polyvinyl chloride resin, polypropylene resin, polycarbonate, dibutyl phthalate, ethyl acetate, KH550 silane coupling agent and reinforcing filler is 100:20:5:1: 30:2.1:5.

Embodiment 2

[0061] 1) First mix polyvinyl chloride resin (weight-average molecular weight of 25,000), polypropylene resin (weight-average molecular weight of 40,000), polycarbonate, dibutyl phthalate, ethyl acetate and silane of the brand KH550 After the coupling agent is mixed, it is heat-treated at 180°C for 3.5 hours to obtain the mixture M1;

[0062] 2) Add the reinforcing filler W2 to the mixture M1, and heat-treat at 195°C for 1.5h to prepare the mixture M2;

[0063] 3) Molding and processing the mixture M2 at 190° C. to obtain the high-strength mildew-proof wall hanging board; denoted as A2.

[0064] Among them, the dosage ratio of polyvinyl chloride resin, polypropylene resin, polycarbonate, dibutyl phthalate, ethyl acetate, silane coupling agent of brand KH550 and reinforcing filler is 100:40:10:3: 40:3.5:12.

Embodiment 3

[0066] 1) First mix polyvinyl chloride resin (weight-average molecular weight of 30,000), polypropylene resin (weight-average molecular weight of 50,000), polycarbonate, dibutyl phthalate, ethyl acetate and KH550 silane After the coupling agent is mixed, it is heat-treated at 190°C for 4 hours to obtain the mixture M1;

[0067] 2) Add the reinforcing filler W3 to the mixture M1, and heat-treat at 205°C for 2 hours to prepare the mixture M2;

[0068] 3) Molding and processing the mixture M2 at 195° C. to obtain the high-strength mildew-proof wall-hanging board; denoted as A3.

[0069] Among them, the dosage ratio of polyvinyl chloride resin, polypropylene resin, polycarbonate, dibutyl phthalate, ethyl acetate, silane coupling agent of brand KH550 and reinforcing filler is 100:50:15:5: 50:5.2:15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com