Solar cell secondary silk-screen printing and four-lens positioning integrated device

A solar cell and screen printing technology, applied in screen printing, printing, printing presses, etc., can solve the problems of errors, low precision, low production efficiency, etc., achieve fast alignment speed, eliminate human errors, and expand production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

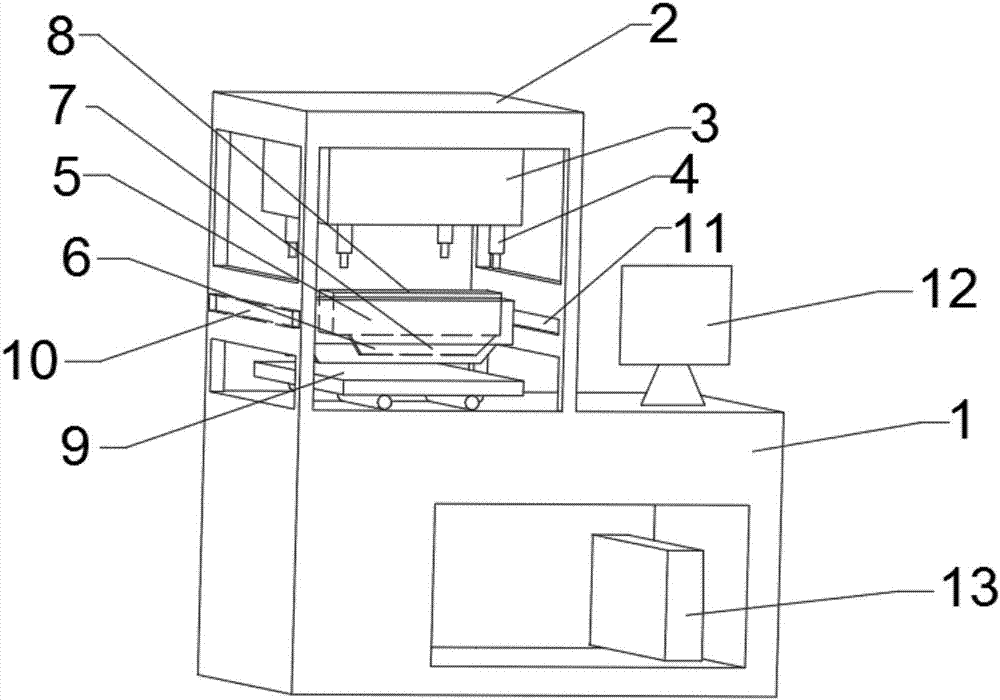

[0013] like figure 1 As shown, a secondary screen printing and four-eye positioning integrated device for solar cells, an operating table 1, a support frame 2, a large servo controller 3, a camera 4, a first small servo controller 5, and a first printing head 6 , the second printing head 7, the first small servo controller 8, the printing platform 9, the first slide rail 10, the second slide rail 11, the display 13 and the host computer 13; For supporting the large servo controller 3 and the camera 4, the first small servo controller 5, the first printing head 6, the second printing head 7, and the first small servo controller 8 are placed on the printing platform 9. On the left and right sides, the printing platform 9 is placed directly under the camera 4. After cooperation, a four-eye positioning integrated printing automation integrated dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com