A gradient heat insulation layer and its preparation method and device

A technology for preparing devices and heat insulation layers, applied in lamination devices, transportation and packaging, heat exchange equipment, etc., can solve problems such as unevenness, difficulty in sticking materials to inner walls, etc., and achieve the effect of meeting the requirements of processing accuracy and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for preparing a gradient heat insulation layer.

[0037] The method for preparing a gradient thermal insulation layer provided by the present invention includes: Step 1: Cut two or more thermal insulation materials according to the size of the inner surface of the workpiece to be insulated; Step 2: Apply on the inner surface of the workpiece The first adhesive is to paste the cut insulation materials on the inner surface of the workpiece in turn, and bond the two adjacent insulation materials with the adhesive; Step 3: After the pasting is completed, apply the insulation material to the Spray two or more different concentrations of immersion liquid on the surface, and the concentration is the mass concentration; after drying, the gradient heat insulation layer is obtained, and the heat insulation material is a flexible porous heat insulation material. The immersion liquid is a liquid with hardening characteristics after drying, and the spray...

Embodiment

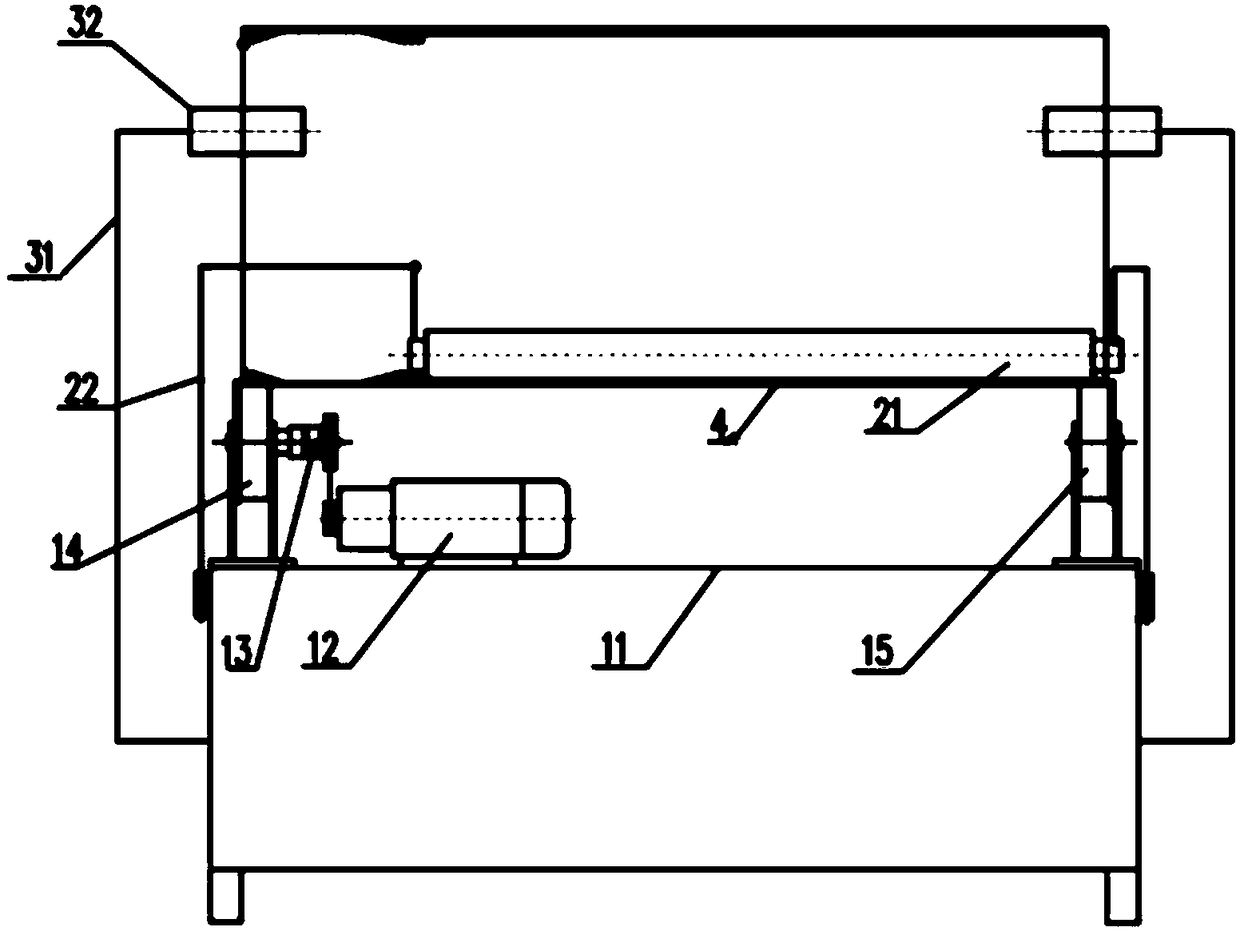

[0071] This embodiment provides a method for preparing the gradient heat insulation layer using the gradient heat insulation layer preparation device provided by the present invention. The device provided in this embodiment is as figure 1 Shown.

[0072] The gradient heat insulation layer for cylindrical workpieces and its coating method and device provided in this embodiment can be applied to large-sized cylindrical workpieces. The length of the work piece is 1.9 meters, the diameter is 0.5 meters, the cylinder of the work piece is welded, and the design depth of the groove for covering the heat insulation material is 7mm. There are actually unevenness. The maximum height difference is 1.2mm and the maximum covering size is 7.8mm. The specific implementation is to bond multiple layers of thermal insulation materials in the workpiece and then perform gradient hardening.

[0073] Among them, according to the working temperature of the workpiece, alumina fiber paper and aluminum si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com