A Highly Sensitive Optical Fiber Curvature Sensing Structure with Temperature Insensitivity

A high-sensitivity and sensitive-characteristic technology, applied in the field of high-sensitivity fiber optic curvature sensing structure, can solve the problem that the fiber optic curvature sensor is easily affected by temperature, and achieve the effect of suppressing the interference of curvature characteristics and temperature characteristics, high sensitivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solution and advantages of the present invention clearer, the specific structure, principle and structural optimization process of the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

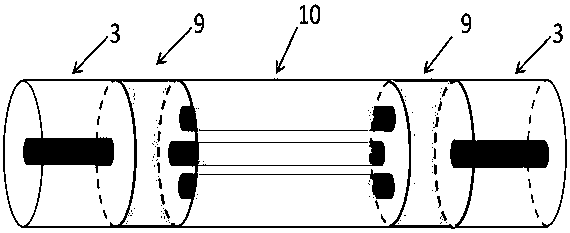

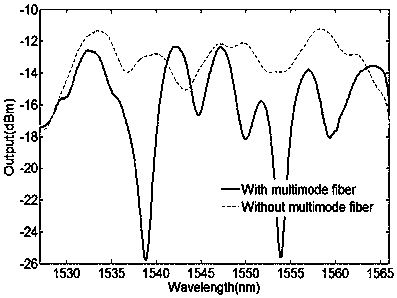

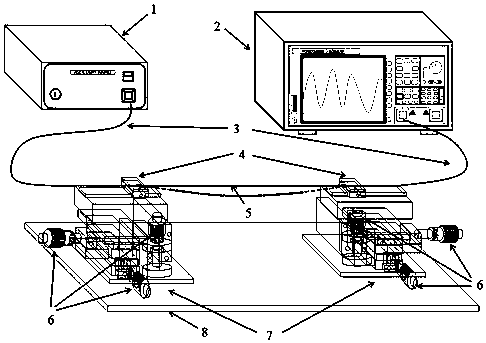

[0027] The present invention proposes a high-sensitivity optical fiber curvature sensing structure with temperature insensitivity, such as figure 1As shown, the three-core optical fiber is used as the central sensitive element, and the three cores of the three-core optical fiber are arranged in an equilateral triangle, the radius of the core is r, and the distance between the cores is d. The broad-spectrum light enters the multimode fiber 9 through the single-mode fiber 3, excites multiple transmission modes, and the transmission mode field becomes larger, and then enters the three-core fiber 10, and the three core modes independently transmit a dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com