Method for enhancing heat transfer performance of nano suspension

A technology of nano-suspension and heat transfer performance, applied in the field of strengthening heat transfer, can solve the problems of weakened heat transfer performance of nano-suspension, unstable and lasting thermal properties, poor dispersion stability, etc., and achieves a narrow particle size distribution range. , low cost, and the effect of improving heat transfer performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) 5g sodium dodecylbenzenesulfonate SDBS surfactant and 15gCuO nanoparticles are added to 980g deionized water, then the sample is placed in a constant temperature magnetic stirrer, and the magnetic stirring speed of 500rpm is set for magnetic stirring Stir, and magnetically stir for 30 minutes to make a mixed solution;

[0025] (2) Put the mixed solution into an ultrasonic cleaner for ultrasonic dispersion for 2 hours, and the ultrasonic frequency is 40kHz to obtain sodium dodecylbenzenesulfonate SDBS surfactant with a mass concentration of 0.5% and CuO nanoparticles with a mass concentration of 1.5%. % CuO nanoparticles suspension.

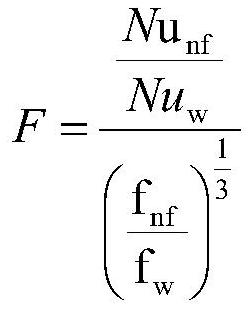

[0026] (3) Pour the prepared CuO nano-suspension into the experimental system, turn on the system for flow heat transfer cycle, adjust the fluid flow rate, record the experimental data and comprehensively analyze the flow and heat transfer characteristics of the nano-suspension. When the Reynolds number reached 3070, the comprehensive ...

Embodiment 2

[0028] (1) 10g polyvinylpyrrolidone PVP surfactant and 10gSiO 2 Nanoparticles were added to 980g deionized water, then the sample was placed in a constant temperature magnetic stirrer, 500rpm magnetic stirring speed was set to carry out magnetic stirring, and magnetic stirring was made into a mixed solution for 30 minutes;

[0029] (2) Put the mixed solution into an ultrasonic cleaner for ultrasonic dispersion for 2 hours, and the ultrasonic frequency is 40kHz to obtain polyvinylpyrrolidone PVP surfactant with a mass concentration of 1.0%, SiO 2 Nanoparticle mass concentration of 1.0% SiO 2 Nanoparticle suspension.

[0030] (3) The prepared SiO 2The nano-suspension is poured into the experimental system, the experimental system is turned on for flow heat transfer cycle, the fluid flow rate is adjusted, the experimental data is recorded and the flow and heat transfer characteristics of the nano-suspension are comprehensively analyzed. When the Reynolds number reached 3045, t...

Embodiment 3

[0032] (1) 15g cetyltrimethylammonium bromide CTAB surfactant and 20g SiC nanoparticles are added to 965g deionized water, then the sample is placed in a constant temperature magnetic stirrer, and 500rpm magnetic stirrer speed is set for Magnetic stirring, magnetic stirring was made mixed solution for 30 minutes;

[0033] (2) Put the mixed solution into an ultrasonic cleaner for ultrasonic dispersion for 2 hours, and the ultrasonic frequency is 40kHz to obtain cetyltrimethylammonium bromide CTAB surfactant mass concentration of 1.0%, SiC nanoparticle mass concentration 1.0% SiC nanoparticle suspension.

[0034] (3) Pour the prepared SiC nano-suspension into the experimental system, turn on the experimental system for flow heat transfer cycle, adjust the fluid flow rate, record the experimental data and comprehensively analyze the flow and heat transfer characteristics of the nano-suspension. When the Reynolds number reaches 3055, the comprehensive flow and heat transfer perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Reynolds number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com