Method for strengthening mechanical property of FDM 3D-printed piece

A 3D printing and high-performance technology, applied in the direction of 3D object support structure, additive manufacturing, manufacturing tools, etc., can solve the problems of FDM application range limitation, low bonding strength between layers, poor overall performance of parts, etc., and achieve easy batch operation , low cost of raw materials, and the effect of enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

[0017] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following embodiments are described in detail together with the accompanying drawings.

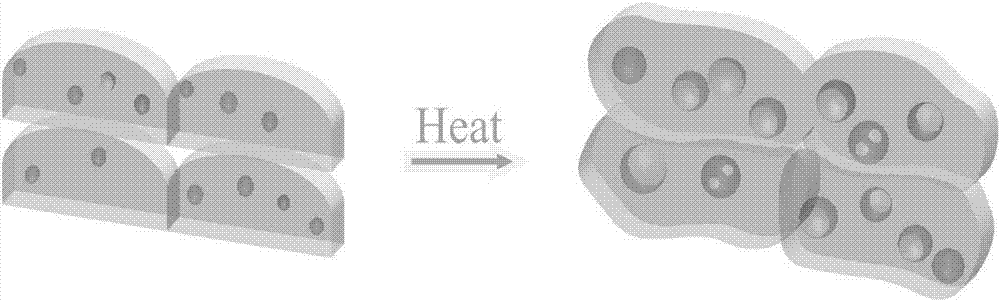

[0018] Modified polyethylene wax is used as the matrix, its melt index is 19g / 10min, and its melting point is about 95°C; AkzoNobel Expancel 930DU120 thermally expandable microspheres are used, and its initial expansion temperature is 120°C. Add 2% expanded microspheres into the matrix, mix well, and prepare FDM 3D printing wire by twin-screw blending. The diameter of the wire is about 1.75mm.

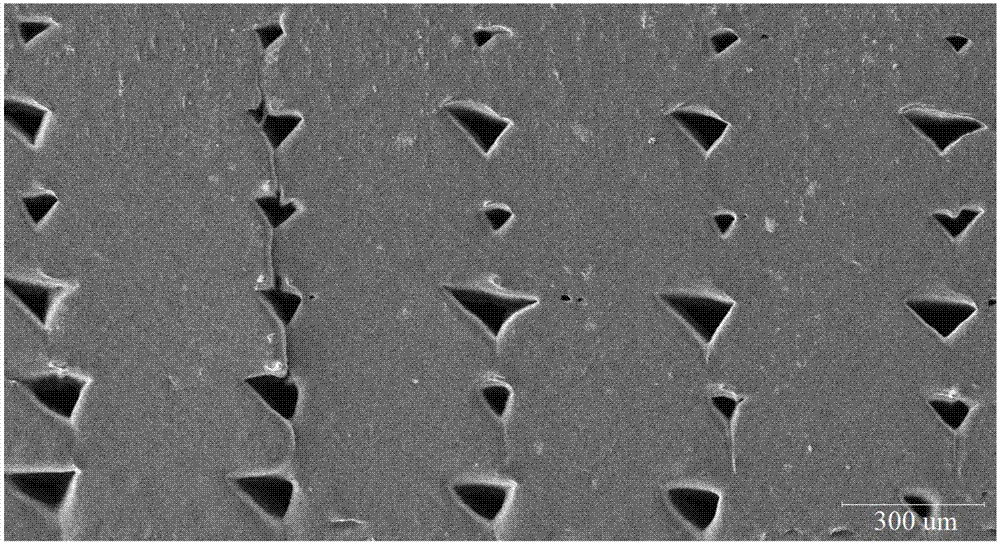

[0019] Put the prepared wire into the FDM 3D printer for printing, printing parameters: nozzle temperature 100°C, nozzle diameter 0.5mm, height of each layer 0.2mm, filling degree 100%.

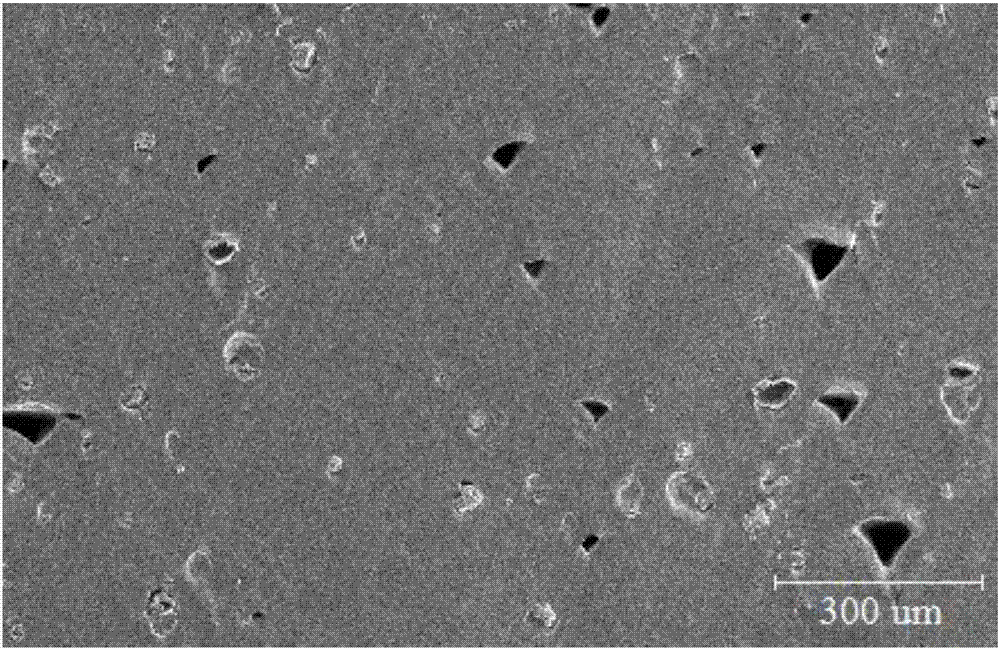

[0020] A flat press is used to hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com