Mill work state adjusting method and device

A technology of working state and mill, applied in the field of data processing, can solve problems affecting the working efficiency of the mill, and achieve the effect of timely adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

[0073] In order to make it easier for those skilled in the art to understand the technical solutions provided by the embodiments of the present disclosure, the following explanations are given first.

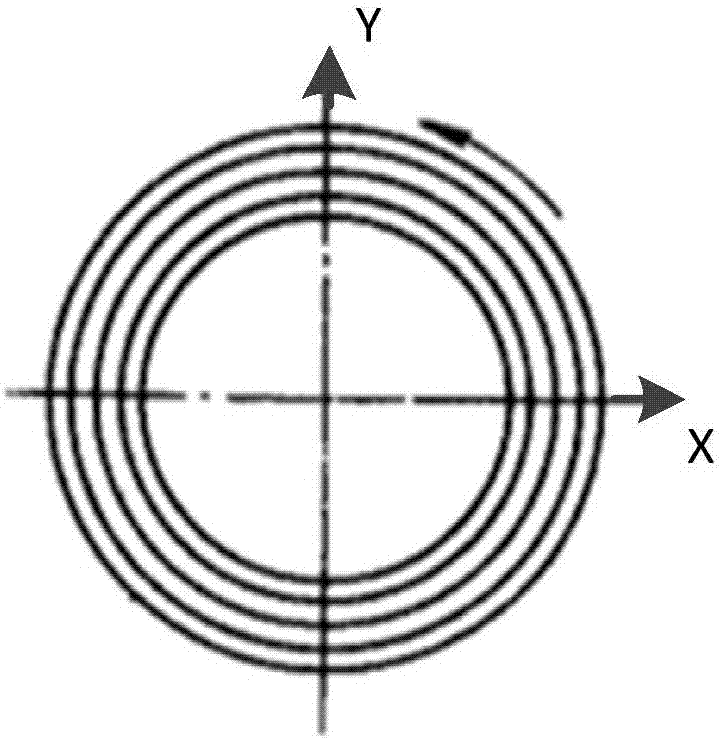

[0074] Usually, the inner wall of the cylinder used for mixing materials and grinding balls is provided with a liner. When the mill rotates, the grinding medium is attached to the liner and rotates with the cylinder under the action of centrifugal force and friction force. When it reaches a certain height After that, it is thrown down by its own gravity.

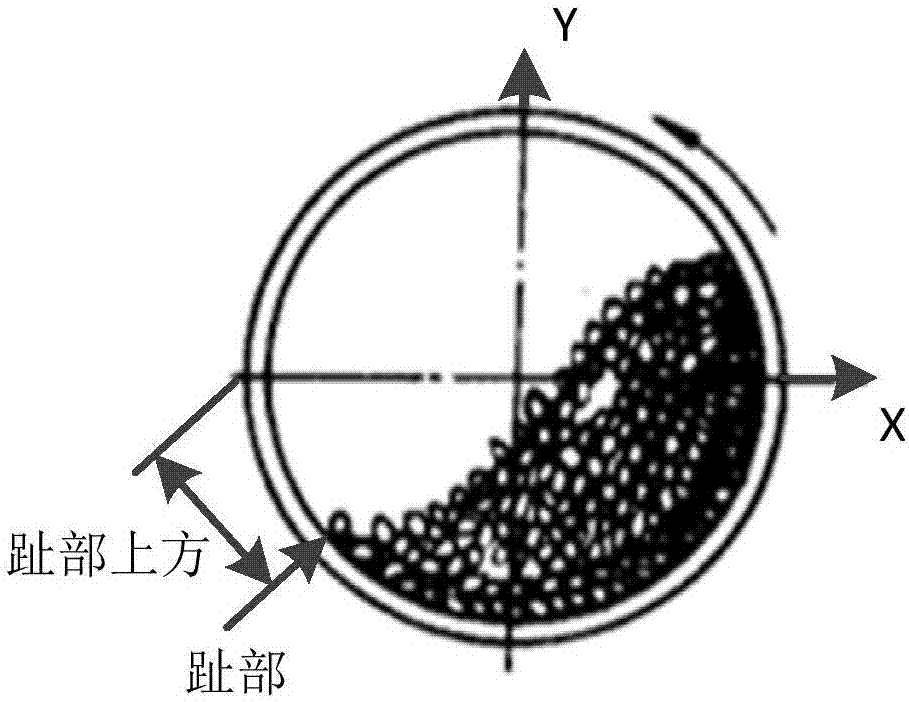

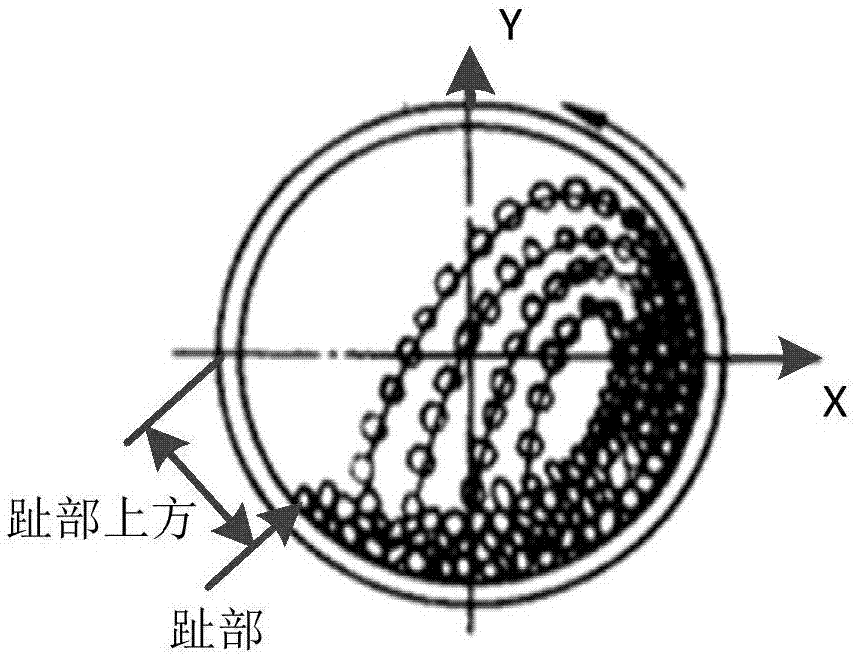

[0075] In the actual application process, as the mill speed increases from low to high, the motion state ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com