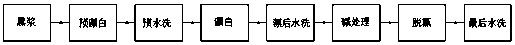

Refined Cotton Bleaching Process

A refined cotton and process technology, which is applied in the field of bleaching and refined cotton bleaching process, can solve the problems of increasing the cost of wastewater treatment of enterprises, deteriorating bleaching effect, and increasing production costs, so as to reduce the number of bleaching times and water consumption, and reduce the amount of escape , increase the effect of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Refined cotton bleaching process, the specific production process is as follows:

[0015] a. Pre-bleaching: first discharge 25t of black pulp formed after cooking into the bleaching tank, then inject 25t of bleached wastewater into the bleaching tank, then add hydrochloric acid solution, adjust the pH value to 5, and then inject 5t into the bleaching tank The activator sodium hypochlorite solution, the available chlorine is controlled at 0.8g / L, then the agitator is turned on, after stirring for 28min, drain 25t to the sewage pool;

[0016] b. Pre-washing: use the water in the recovery pool to wash the black pulp. The washing time is 17 minutes. During washing, the water is discharged to the cooling water pool. When washing, water is drained while water is poured in, and the liquid level in the bleaching pool is kept constant;

[0017] c. Bleaching: Add 1.8t bleaching solution to the bleaching tank, the content of chlorine dioxide in the bleaching solution is 1.3g / L, th...

Embodiment 2

[0025] Refined cotton bleaching process, the specific production process is as follows:

[0026] a. Pre-bleaching: first discharge 28t of black pulp formed after cooking into the bleaching tank, then inject 20t of bleached wastewater into the bleaching tank, then add hydrochloric acid solution, adjust the pH value to 6, and then inject 7t into the bleaching tank The activator sodium hypochlorite solution, the available chlorine is controlled at 0.6g / L, then the agitator is turned on, after stirring for 26min, drain 30t to the sewage pool;

[0027] b. Pre-washing: use the water in the recycling pool to wash the black pulp. The washing time is 18 minutes. During washing, the water is discharged to the cooling pool. During washing, the water is drained while water is poured in, and the liquid level in the bleaching pool is kept constant;

[0028] c. Bleaching: Add 1t of bleaching solution to the bleaching tank, the content of chlorine dioxide in the bleaching solution is 1.2g / L, ...

Embodiment 3

[0036] Refined cotton bleaching process, the specific production process is as follows:

[0037] a. Pre-bleaching: first discharge 30t of black pulp formed after cooking into the bleaching tank, then inject 25t of bleached wastewater into the bleaching tank, then add hydrochloric acid solution, adjust the pH value to 4, and then inject 8t into the bleaching tank The activator sodium hypochlorite solution, the available chlorine is controlled at 0.5g / L, then the agitator is turned on, after stirring for 23min, drain 35t to the sewage pool;

[0038] b. Pre-washing: use the water in the recovery pool to wash the black pulp. The washing time is 15 minutes. During washing, the water is drained to the cooling pool. During washing, water is drained while water is poured in, and the liquid level in the bleaching pool is kept constant;

[0039] c. Bleaching: Add 2t of bleaching solution to the bleaching pool, the content of chlorine dioxide in the bleaching solution is 1.2g / L, the cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com