Moving bed anaerobic fermentation reactor

An anaerobic fermentation and active bed technology, applied in the direction of gas production bioreactors, biochemical instruments, biochemical equipment and methods, etc., can solve problems such as pH value, difficult temperature control, difficult heat and mass transfer, and large water consumption , to achieve the effect of saving sewage treatment costs, simplifying the treatment process, and occupying less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

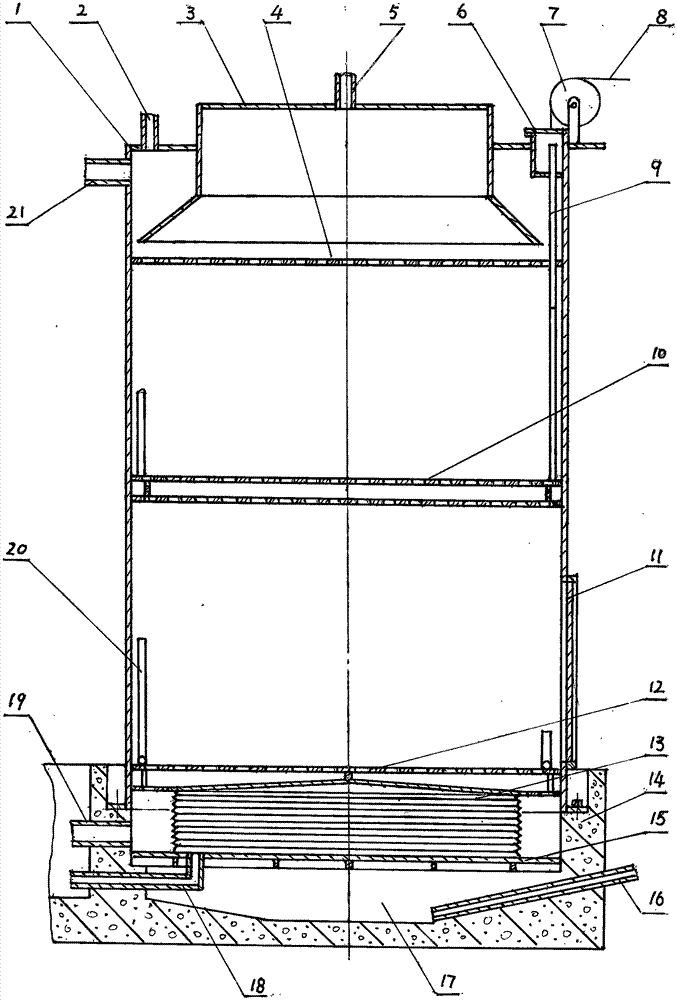

[0017] The accompanying drawing shows that the tank body 1 is a vertical device, the upper part is provided with a gas collecting hood 3, and the lower part of the gas collecting hood is in the tank body 1. The top of the gas collecting hood is provided with a biogas outlet pipe 5 communicating with it, and the outlet pipe communicates with a biogas storage tank (not shown in the figure). The baffle plate 4 is arranged under the gas collecting hood 3, and its periphery is fixed on the inner wall of the tank body 1. The baffle is a perforated plate. The bottom of baffle plate 4 is provided with upper movable bed 10, and above upper movable bed is provided with 4 telescopic suspension rods 9, and the suspension rod top is connected with the wire rope 8 on the pulley 7 that is fixed on tank body 1 top. Wire rope is connected with winch (not shown in the figure). When the upper movable bed 10 rises to a predetermined position, it can be fixed. Suspender rod 9 tops and wire rope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com