Method for rapidly preparing metal-organic framework (MOF) compound having controllable structure by using electrochemical method

A metal-organic framework and electrochemical technology, which is applied in the field of rapid preparation of structure-controllable metal-organic framework compounds by electrochemical methods, can solve the problems of single metal-organic framework morphology and uncontrollable synthesis process, and achieve short synthesis time and smooth synthesis process. The effect of simplicity and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

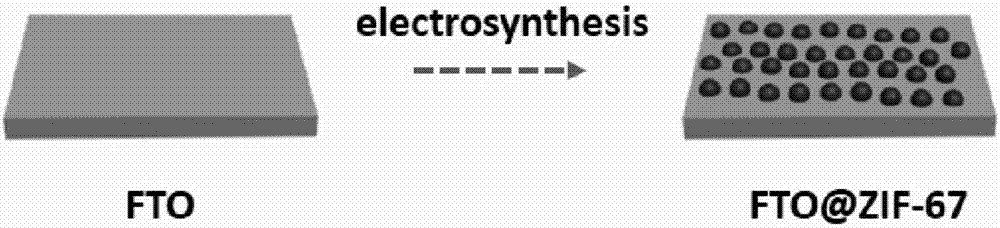

[0020] Synthesis of ZIF-67 nanomaterials on the surface of FTO:

[0021] a: Ultrasonic the conductive substrate FTO with absolute ethanol, acetone and deionized water respectively for 10 minutes to remove impurities on the surface;

[0022] b: Prepare 1mg / mL cobalt nitrate (Co(NO 3 ) 2 ), 0.5mg / mL1,2-dimethylimidazole, methanol mixed solution 50mL as the electrolyte solution;

[0023] c: In the electrolyte solution prepared in step b, FTO is used as the working electrode, the saturated calomel electrode is used as the reference electrode, and the platinum wire is used as the counter electrode, and ZIF-67 is directly grown on the FTO by the constant potential method, and the electrochemically synthesized potential Set to -0.9V, the synthesis time is 200s, and the synthesis temperature is 25°C.

Embodiment 2

[0025] Synthesis of ZIF-67 nanomaterials on CoAl-LDH@Ni foam:

[0026] a: Ultrasonic the conductive substrate Ni foam with absolute ethanol, acetone and deionized water respectively for 10 minutes to remove impurities on the surface;

[0027] b: Soak the Ni foam obtained in step a in 1 mg / mL cobalt nitrate (Co(NO 3 ) 2 ) and 1mg / mL aluminum nitrate (Al(NO 3 ) 3 ) and 1mg / mL urea in a high-temperature and high-pressure reactor, put the reactor in an oven, and react at 110°C for 24 hours to obtain CoAl-LDH grown on Ni foam, that is, CoAl-LDH@Ni foam.

[0028] c: prepare 1mg / mL cobalt nitrate (Co(NO 3 ) 2 ), 50mL of a mixed solution of 0.5mg / mL1,2-dimethylimidazole and methanol was used as the electrolyte solution;

[0029] d: In the electrolyte solution prepared in step c, CoAl-LDH@Ni foam was used as the working electrode, the saturated calomel electrode was used as the reference electrode, and the platinum wire was used as the counter electrode, and CoAl-LDH@FTO was dire...

Embodiment 3

[0031] Synthesis of ZIF-8 nanomaterials on ZnO@Ni foil:

[0032] a: Ultrasonic the conductive substrate Ni foil with absolute ethanol, acetone and deionized water respectively for 10 minutes to remove impurities on the surface;

[0033] b: Soak the Ni foil obtained in step a in 100 mL of absolute ethanol containing 0.06M zinc acetate, and calcinate at 350°C for 30 minutes. Put the calcined Ni foil into a high-temperature and high-pressure reactor containing 0.06M zinc nitrate and 0.06M hexamethylenetetramine (HMT), react at 100°C for 24 hours, wash it with deionized water and ethanol, Dry at room temperature to obtain ZnO nanorod arrays grown on Ni foil, that is, ZnO@Nifoil.

[0034] c: prepare 1mg / mL zinc nitrate (Zn(NO 3 ) 2 ), 0.5mg / mL1,2-dimethylimidazole, methanol mixed solution 50mL as the electrolyte solution;

[0035] d: In the electrolyte solution prepared in step c, ZnO@Ni foil was used as the working electrode, the saturated calomel electrode was used as the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com