Preparation method of addition-type liquid silicon rubber tackifier

A technology of liquid silicone rubber and tackifier, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of decreased cohesive force, low molecular weight of coupling agent, and general compatibility, etc., to achieve Increase the bonding effect and reduce the effect of gel formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

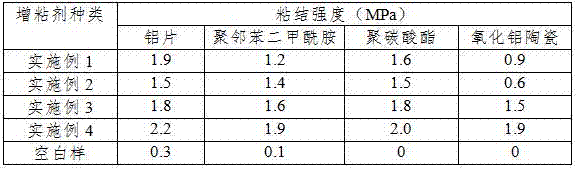

Examples

Embodiment 1

[0016] Add 1000g of dimethyldimethoxysilane into the reaction kettle with mechanical stirring, reflux condenser and thermometer, slowly add 200g of 5% hydrochloric acid aqueous solution dropwise under stirring, and raise the temperature to 60°C for reaction after the dropwise addition is completed 5h, after vacuuming to remove moisture and small molecules, add 1.5g of tetra-n-butyl titanate and 300g of γ-glycidyl etheroxypropyltrimethoxysilane, heat up to 80°C for 5h, vacuumize and heat up to 160°C to remove Low boiling matter, a light yellow transparent liquid product was obtained.

Embodiment 2

[0018] Add 800g of dimethyldimethoxysilane and 200g of diphenyldimethoxysilane into the reaction kettle with mechanical stirring, reflux condenser and thermometer, and slowly add 200g of 5% hydrochloric acid aqueous solution dropwise under stirring After the dropwise addition is completed, the temperature is raised to 60°C for 5 hours, and after vacuuming to remove moisture and small molecules, add 1.5g of tetra-n-butyl titanate, 50G of vinyltrimethoxysilane and 250g of γ-glycidyl etheroxypropyl trimethoxy For silane, heat up to 80°C for 5 hours, vacuumize and heat up to 160°C to remove low boilers, and obtain a light yellow transparent liquid product.

Embodiment 3

[0020] Add 1000g of dimethyldimethoxysilane into the reaction kettle with mechanical stirring, reflux condenser and thermometer, slowly add 200g of 5% hydrochloric acid aqueous solution dropwise under stirring, and raise the temperature to 60°C for reaction after the dropwise addition is completed 5h, after vacuuming to remove moisture and small molecules, add 1.5g of organotin complex, 150g of γ-glycidyloxypropyltrimethoxysilane and 150g of γ-methacryloxypropyltrimethoxysilane, and heat up to React at 80°C for 5h, vacuumize and heat up to 160°C to remove low boilers to obtain a light yellow transparent liquid product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com