Treatment method of oily sludge on offshore platform

An offshore platform and treatment method technology, applied in water/sludge/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. effect, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

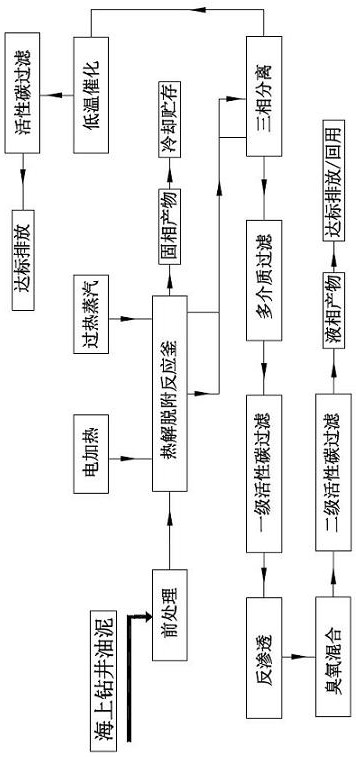

[0029] like figure 1 As shown, the treatment methods of oily sludge on offshore platforms include pretreatment, thermal desorption and desorption treatment, tail gas treatment, and wastewater treatment;

[0030] The pretreatment steps include sorting and crushing of foreign matter. The sorted oily sludge is transported to the thermal desorption reaction kettle, and the foreign matter is crushed and then transported to the thermal desorption reaction kettle.

[0031] The thermal desorption and desorption treatment is completed in the thermal desorption and desorption reactor, and the inner wall of the thermal desorption and desorption reactor is heated simultaneously with the interior of the thermal desorption and desorption reactor. The interior of the thermal desorption reaction kettle is heated by superheated steam, and the superheated steam is introduced from the lower part of the thermal desorption reaction kettle, and then sprayed from the central axis of the thermal deso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com