Laser real-time dynamic cladding repair and stress control system and method of damaged gears

A real-time dynamic laser cladding technology, which is applied to laser welding equipment, belts/chains/gears, components with teeth, etc., can solve the problem of inability to eliminate pores in the cladding layer, sparse structure, and repair gear performance. Guarantee and other issues to achieve the effect of eliminating defects, improving repair efficiency, and reducing repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

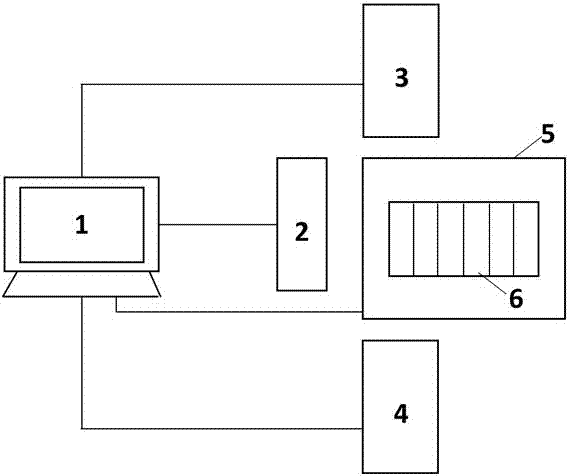

[0040] Damaged gear laser real-time dynamic cladding repair and stress control system, including optical infrared coupling dynamic monitoring and measurement system connected to the central control system, laser cladding system, laser impact system, five-axis linkage platform;

[0041] The central control system drives the laser cladding system and the laser shock system to repair the damaged gear according to the information of the damaged gear fixed on the five-axis linkage platform fed back by the optical infrared coupling dynamic monitoring and measurement system in real time.

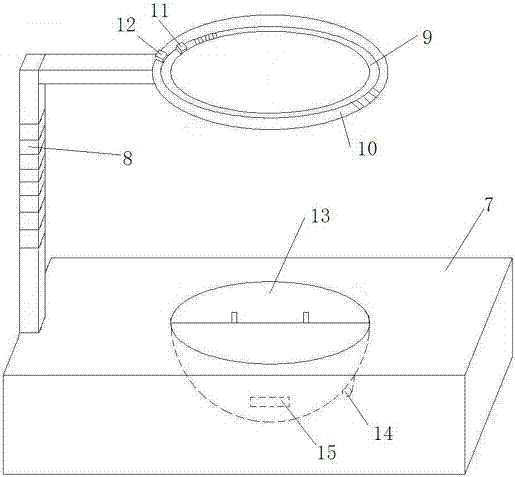

[0042] The five-axis linkage platform includes a hemispherical table embedded in the platform and a ring frame connected to the platform through a support column. The joint surface of the platform and the hemispherical platform is provided with an X-axis and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com