Spraying castable working performance test device and test method

A technology of working performance and testing method, which is applied in the field of refractory castables, can solve problems such as the inability to reflect the flow state of sprayed castables, the deviation of test methods from reality, and misleading production personnel, so as to achieve intuitive and reliable results, improve work performance and use performance , the effect of optimizing the configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

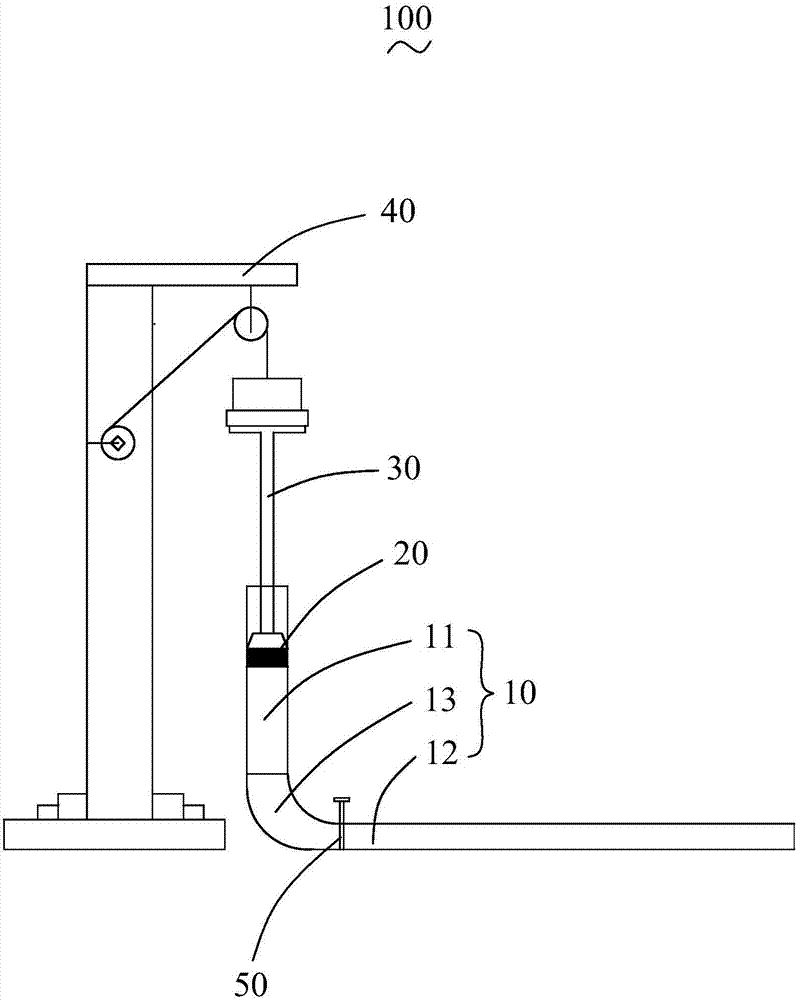

[0043] In this embodiment, the inner diameters of the vertical pipe 11 and the horizontal pipe 12 of the injection castable working performance testing device 100 are 75mm and 40mm respectively, and the lengths are 300mm and 800mm respectively. In the method of testing the working performance of the injection castable using this device, each time 3Kg of the injection castable is loaded into the vertical pipeline 11 and the connecting pipeline 13, and the valve 50 is opened after standing for 15 seconds. At the same time, the constant pressure applied to the piston 20 by the adding device 40 is P 1 = 1 MPa.

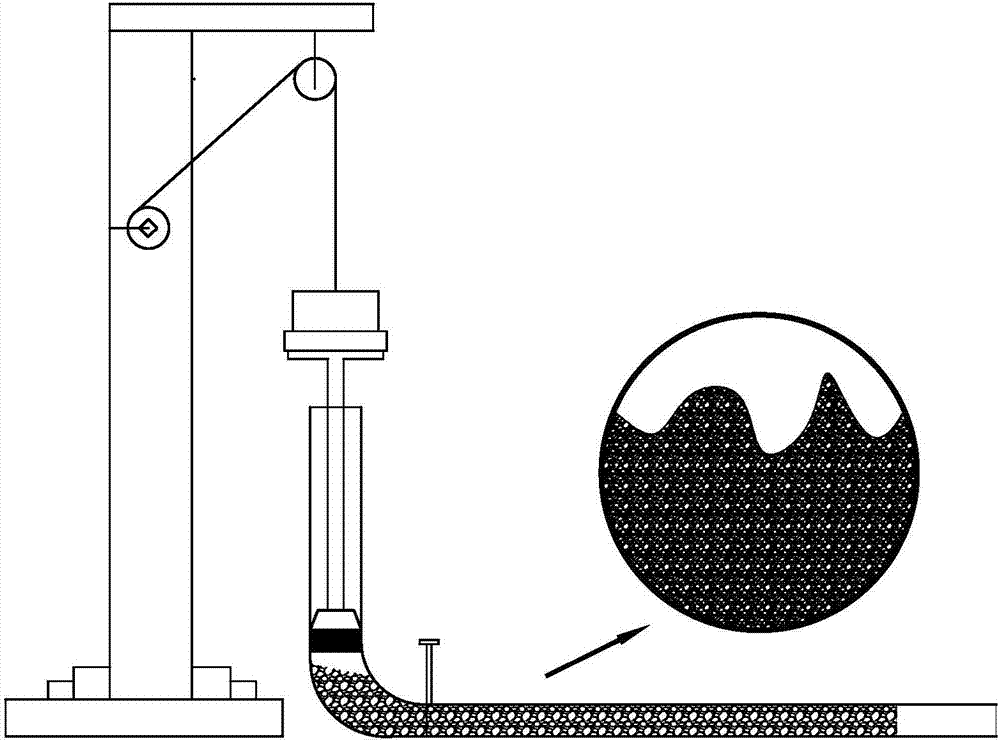

[0044] Please also refer to figure 2 , observing the cured and dried spray castable A in the horizontal pipe 12, it can be seen that the large particles of the spray castable A are concentrated in the lower part of the horizontal pipe 12, and the matrix slurry is distributed in the upper part, and serious segregation occurs. In addition, changing the constant pressure a...

Embodiment 2

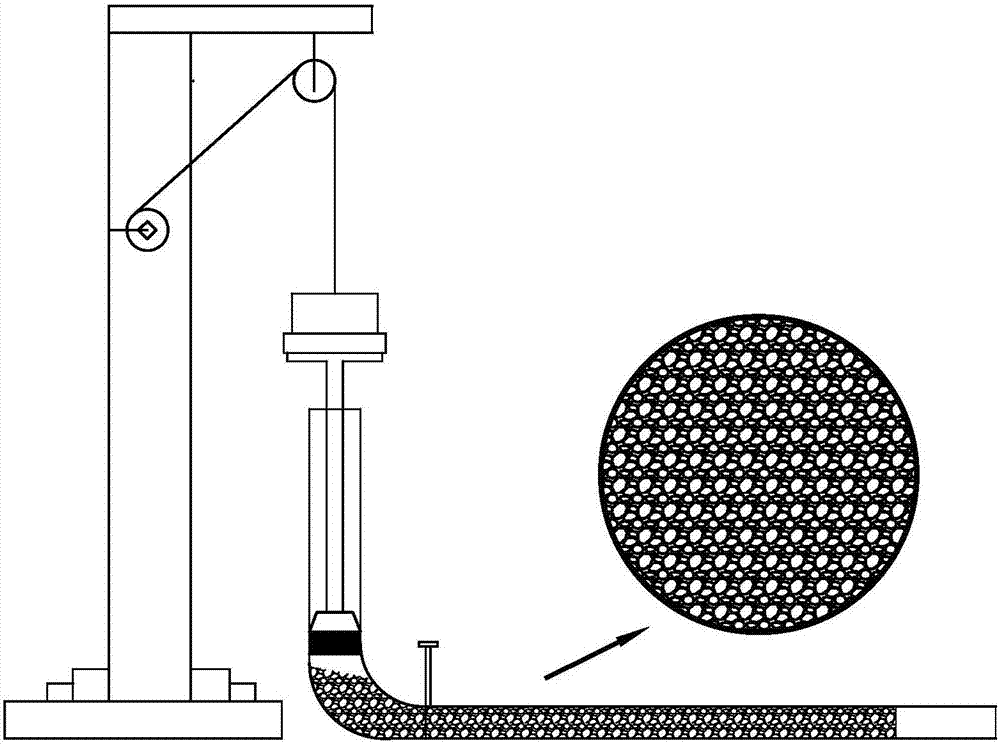

[0046] In this embodiment, the working performance of the sprayed castable B is tested using the working performance test device 100 and parameters described in Example 1. Please also refer to image 3 , observing the spray castable B in the horizontal pipe 12 after curing and drying, it can be seen that the particle distribution of the spray castable B in the horizontal pipe 12 is relatively uniform, and no obvious segregation phenomenon is observed. There is a thin layer of lubricating layer in the place, which shows that the spray castable B works well in the horizontal pipe 12. In addition, the mathematical relationship between pressure and flow rate P=K is obtained by changing the pressure 0 +μ f(V),K 0 If it matches well with μ, it means that the injection castable B is suitable for transportation in the pipeline.

[0047] The working performance test device and test method of the injection castable provided by the present invention can simulate the flow of the inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com