Barrel formwork and construction method thereof

A construction method and technology of barrel mold, which is applied in the field of building materials, can solve problems such as bridge deck icing and freezing, and achieve the effects of reducing self-weight load, reducing the space occupied by pipelines, and reducing the height of floors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

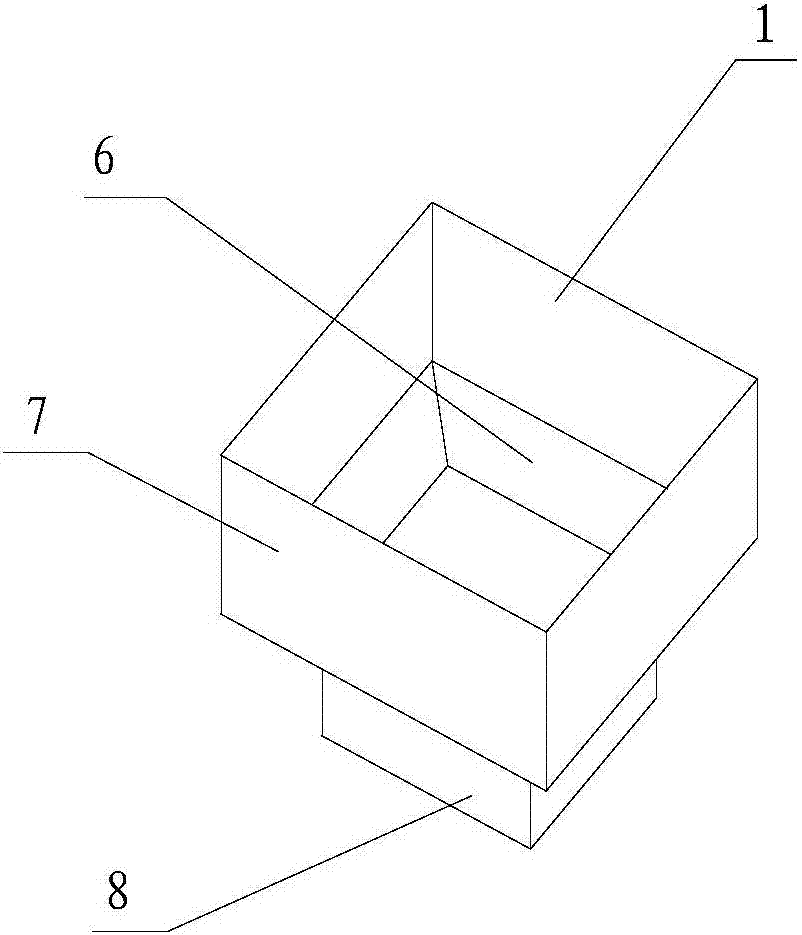

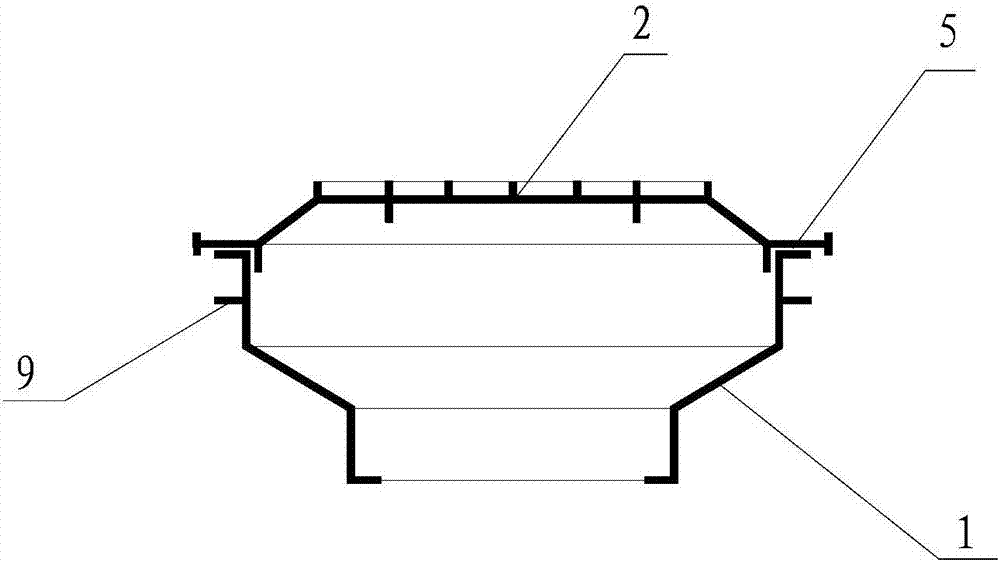

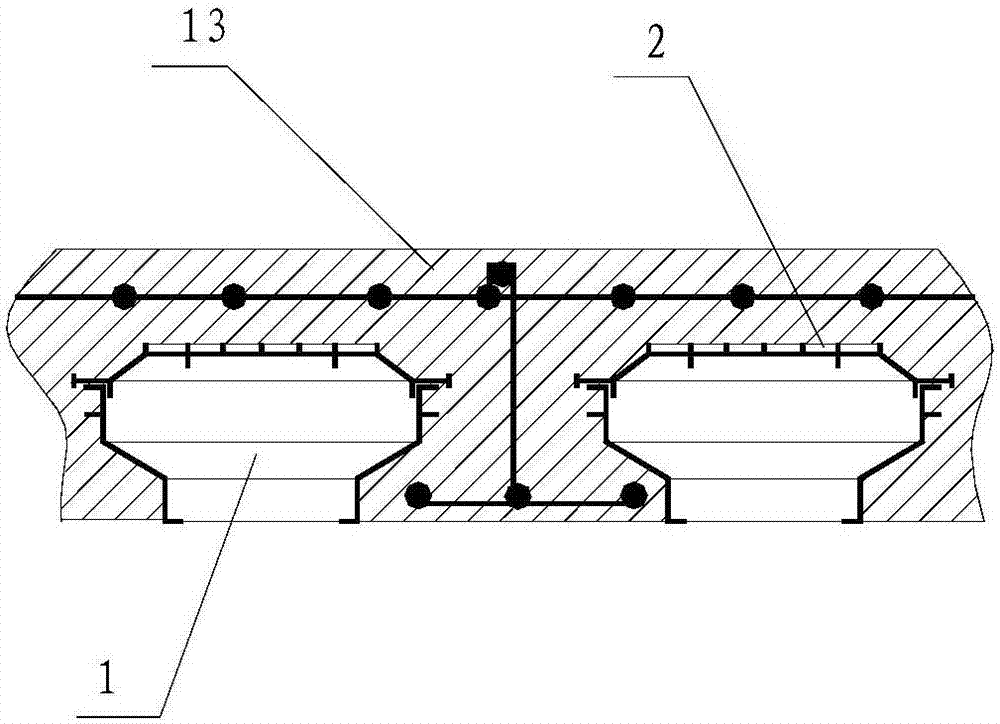

[0041] Embodiment 1: A kind of cylinder mold, comprises cylinder body 1 and end cap 2 as shown in the figure, cylinder body 1 is shaped as a rectangular tubular hollow body, length and width are 600 millimeters, height 125 millimeters, every 25 millimeters is a module ; The shape of the end cover 2 is a pot-shaped rectangular box, the length and width of which correspond to the docking dimensions of the cylinder 1, and the height is 100 mm. It is hot-pressed and formed by recycled waste plastic thin wall material, and it is mass-produced in a factory, with a wall thickness of 3 mm. The butt joint surfaces of the cylinder body 1 and the end cover 2 are in the following form: the four butt joint sides of the end cover 2 are all folded plate slopes, the four butt joint sides of the cylinder body 1 are all V-shaped plate slopes, the joint joint surface 1 and the joint joint surface two 4 is the inclined plane butt joint.

[0042] Further, a barrel mold includes a barrel body 1 an...

Embodiment 2

[0053] Embodiment 2: A kind of cylinder mold, comprises cylinder body 1 and end cap 2, cylinder body 1 shape is rectangular tubular hollow body, length and width are 600 millimeters, height 250 millimeters, every 25 millimeters is a module, end The shape of the cover 2 is a pot-shaped rectangular box, the length and width of which correspond to the butt joint dimensions of the cylinder 1, and the height is 50 mm. It is formed by gypsum casting and mass-produced in a factory, with a wall thickness of 40 mm. The docking surface 1 3 and the docking surface 2 4 are in the following form: the butt joint surfaces of the cylinder body 1 and the end cap 2 are the same, the butt joint surfaces of the two opposite sides are serrated, the concave and convex surfaces correspond, and the buckle surface is concave and convex corresponding to the occlusal butt joint .

[0054] Further, the barrel 1 is manufactured in two sections and connected on site.

[0055] Further, a corner brace 10, ...

Embodiment 3

[0065] Embodiment 3: A kind of cylinder mold, comprises cylinder body 1 and end cap 2, and cylinder body 1 is shaped as rectangular tubular hollow body, and length and width are 600 millimeters, and height is 200 millimeters, and every 25 millimeters is a module; The cover 2 is in the shape of a basin-shaped rectangular box, the length and width of which correspond to the docking dimensions of the cylinder 1, and the height is 80 mm. It is hot-pressed and formed by recycled waste plastic thin wall material, and it is mass-produced in a factory, with a wall thickness of 5 mm. The butt joint surface of the cylinder body 1 and the end cover 2 is in the following form: the four butt joint sides of the cylinder body and the end cover are all the same, the two opposite sides are all zigzag folded plates, the concave part of the two opposite sides corresponds to the convex part, and the butt joint surface It is a concave-convex staggered butt joint.

[0066] Furthermore, the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com