Compound fertilizer, preparation method and application of compound fertilizer

A technology of compound fertilizer and fertilizer synergist, applied in fertilization methods, urea compound fertilizer, application and other directions, can solve the problems of excessive nitrate nitrogen in groundwater, death of aquatic organisms, eutrophication of water bodies, etc. Slow release effect, nutrient utilization efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

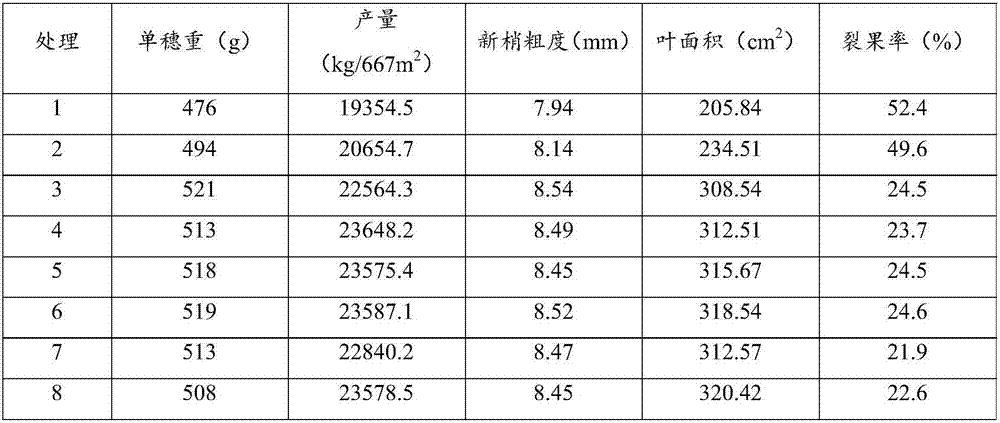

Examples

preparation example Construction

[0055] Wherein the preparation method of active diatomite:

[0056] (1) Take 10-20g of diatomaceous earth and put it in a beaker, add 50-200mL of 0.1-1mol / L NaOH solution, put it in a magnetic stirrer and stir for 2-4h, then centrifuge in a centrifuge at a speed of 5000rpm for 5min, collect Lower diatomaceous earth;

[0057] (2) Add 100-500mL of diatomite to the collected lower layer of diatomite and soak for 10-30min to remove residual NaOH, centrifuge again at 5000rpm for 5min, and re-collect the lower layer of diatomite;

[0058] (3) Add 100-200mL of methanol to the re-collected lower layer of diatomite, magnetically stir for 10-30min, and centrifuge at 5000rpm for 5min to collect the lower layer of diatomite;

[0059] (4) Add 100-200mL 3-aminopropyltriethoxysilane solution with a volume ratio of 10% to the obtained diatomite, stir in a magnetic stirrer at a temperature of 40°C for 20min, and then Centrifuge at 5000rpm for 5min to collect the active diatomaceous earth in ...

Embodiment 1

[0090] Mix and stir the urea of 20 parts by weight, the ammonium sulfate of 15 parts by weight, the monoammonium phosphate of 10 parts by weight, the potassium sulfate of 55 parts by weight, the cyclodextrin of 0.5 parts by weight and the gamma-polyglutamic acid of 0.5 parts by weight, After extruding, granulating and sieving, the compound fertilizer is obtained.

[0091] γ-polyglutamic acid is wettable powder of γ-polyglutamic acid.

Embodiment 2

[0093] The urea of 30 parts by weight, the ammonium sulfate of 10 parts by weight, the monoammonium phosphate of 15 parts by weight, the potassium sulfate of 45 parts by weight, the cyclodextrin of 5 parts by weight and the gamma-polyglutamic acid of 0.2 parts by weight are mixed and stirred, After extruding, granulating and sieving, the compound fertilizer is obtained.

[0094] γ-polyglutamic acid is wettable powder of γ-polyglutamic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com