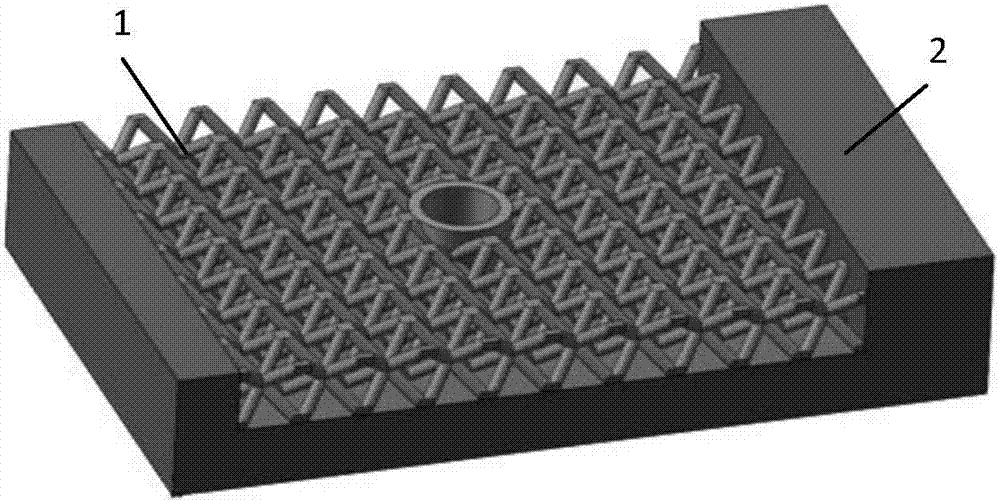

Preparation method of fan-shaped sealing block of dot matrix cooling structure

A technology of cooling structure and lattice structure, which is applied in the field of fan-shaped sealing block preparation, can solve problems such as unmanufacturability, achieve high utilization rate, improve heat insulation and cooling performance, and excellent heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described further below in conjunction with example, but the present invention is not limited to specific embodiment.

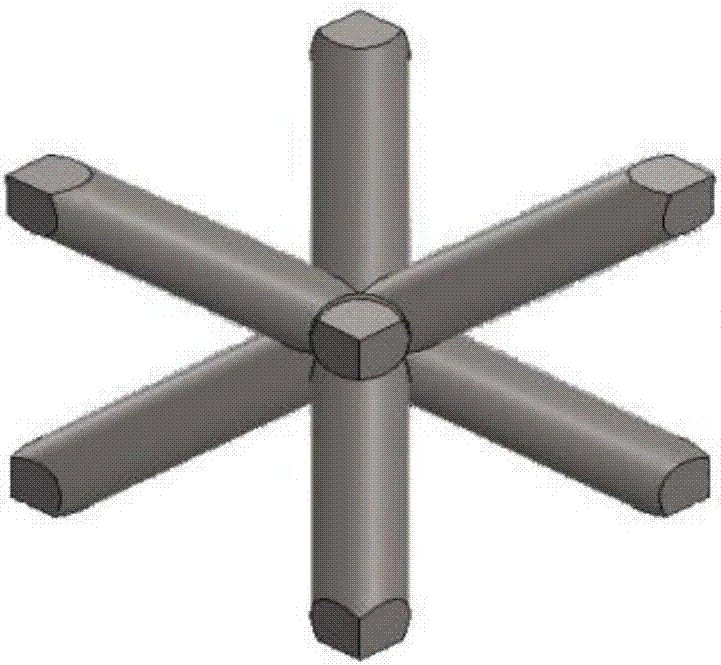

[0034] The fan-shaped sealing block with a lattice structure is prepared by laser selective melting rapid prototyping technology. The lattice structure is composed of lattice units, and each lattice unit is in a tetrahedron, pyramid or kagome configuration, and the lattice structure completely covers the fan-shaped seal. A backplane, using laser selective melting to prepare a fan-shaped sealing block with a lattice structure on the backplane:

[0035] (1) Utilize three-dimensional drawing software (solidworks etc.) to set up the three-dimensional CAD model of the fan-shaped sealing block with lattice structure;

[0036] (2) According to the structural characteristics of the lattice in the fan-shaped sealing block with a new cooling structure, adjust the forming direction of the fan-shaped sealing block to ensure that all lattic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com