Molten iron reladling system and method based on excess steel return line

A return line and molten iron tank technology, which is applied in the direction of casting melt containers, manufacturing tools, metal processing equipment, etc., can solve the problems affecting the control accuracy of automatic steelmaking and many influencing factors, so as to increase the space for process operations and solve the problems Environmental pollution problems, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

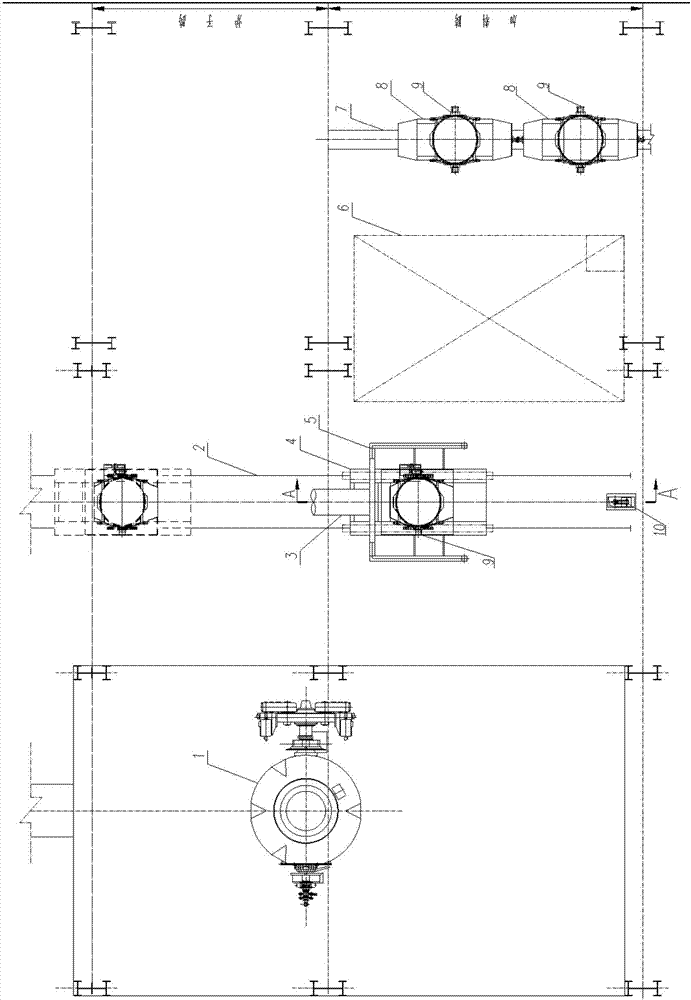

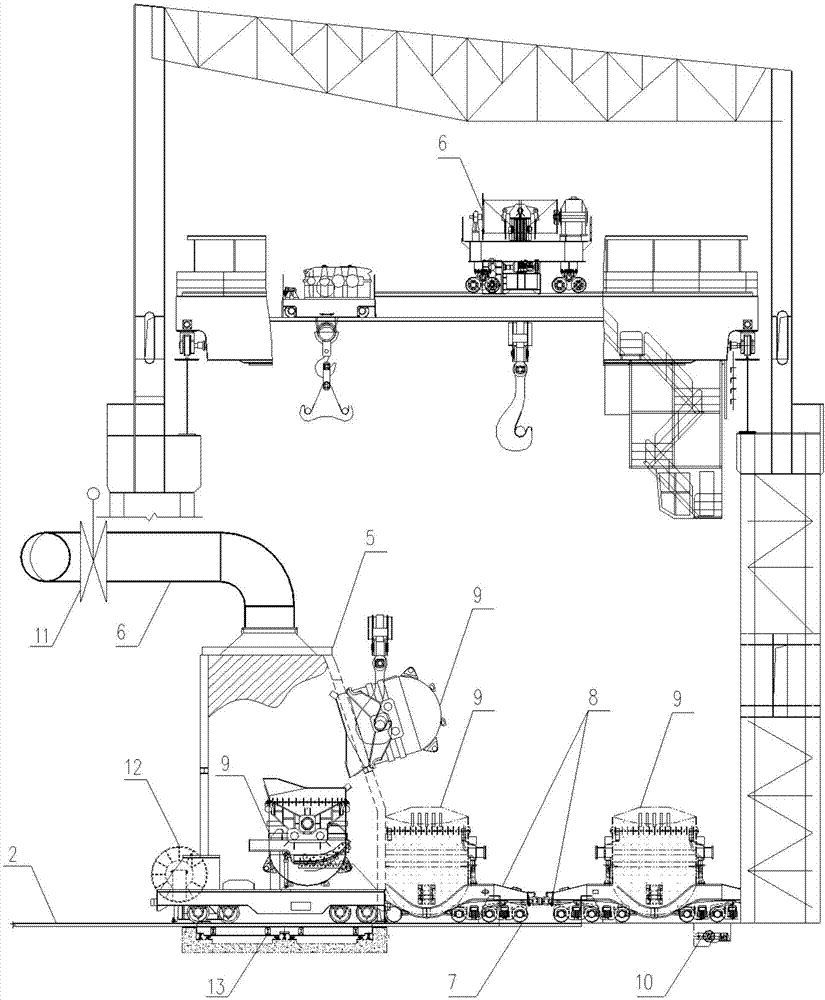

[0036] see Figure 1-2 As shown, the present invention provides a system for pouring molten iron based on the return line of surplus steel, comprising: a feeding span and a furnace span arranged in parallel, connecting the feeding span and the furnace span to the surplus steel return vehicle track 2; the surplus steel return vehicle track 2 A surplus steel return car 4 is set;

[0037] A molten iron pouring system is provided on the track 2 of the return vehicle for remaining steel in the material span; the molten iron pouring system includes a dust treatment device and a weighing device;

[0038] Among them, Yu Gang returns to the car 4 to transport the empty molten iron tank 9 to the molten iron pouring system for weighing. After weighing, the dust treatment device is turned on to pour the molten iron. After the pouring is completed, it is weighed again and calculated according to the two weighings The weight of the molten iron, after weighing, return the remaining steel to...

Embodiment 2

[0054] On the basis of Embodiment 1, an electric butterfly valve 11 is arranged in the dust removal pipe 3 of this embodiment; the electric butterfly valve 11 is opened when the steel is poured, and the electric butterfly valve 11 is closed when the steel is poured.

[0055] Open the electric butterfly valve 11 between the molten iron pouring system and the dust treatment device before pouring the cans; close the electric butterfly valve 11 after the pouring is completed; the smoke and dust generated by the pouring cans are processed by the dust removal system through the dust removal pipe 3 and then discharged up to standard.

Embodiment 3

[0057] On the basis of Embodiment 2, the front and rear walls of the semi-hermetic cover 5 of the present embodiment are provided with openings for entering and exiting the molten iron tank 9 .

[0058] Two openings, one is used for the entry and exit of the surplus steel return car 4, and the other is used for the operation of pouring cans, which can simultaneously operate the two molten iron tanks 9 that need to be poured, saving time. And different operations are carried out in two directions, which also saves the utilization of the space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com