A two-stage water media separation method for coarse coal slime

A sorting technology for coarse coal slime, which is applied in chemical instruments and methods, solid separation, wet separation, etc., can solve problems such as insufficient separation accuracy, decline in separation effect, and difficulty in medium recovery, so as to facilitate management and Normal operation, low cost of technological transformation, and improved de-intermediation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific embodiment, further illustrate the present invention.

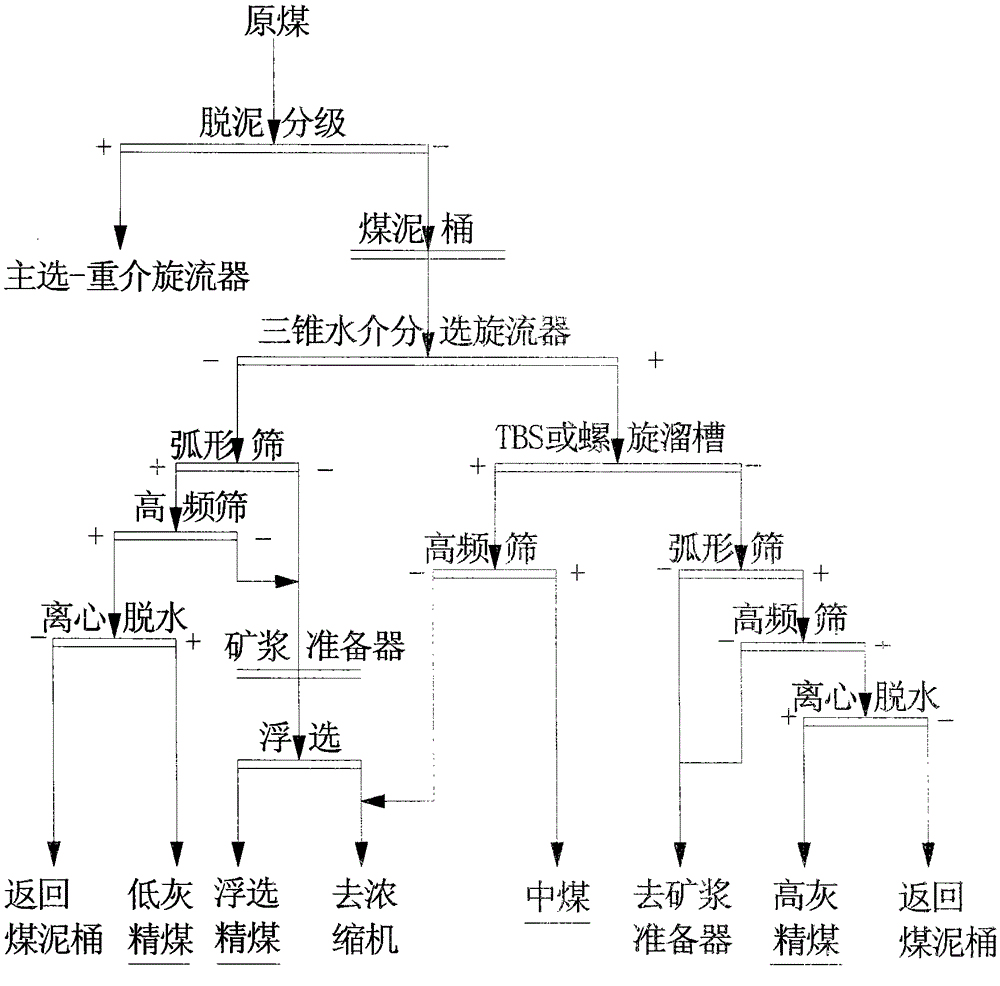

[0029] pass figure 1 It can be seen that a kind of coarse coal slime two-stage water media separation method is characterized in that comprising the following steps:

[0030] In the first step, the raw coal is classified through the desliming sieve with a sieve hole of 0.75mm to 3mm, and the material under the sieve enters the slime bucket, and is directly pumped into the main separation equipment for separation; the material on the grading sieve is fed into the main separation heavy medium sorted in a cyclone.

[0031] In the second step, the main separation equipment for coarse coal slime is the three-cone water-medium separation cyclone. After the coarse coal slime is sorted by the three-cone water-medium separation cyclone, the underflow and overflow are treated separately. The possible deviation Ep value of the above-mentioned three-cone water-medium separation cyclone can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com