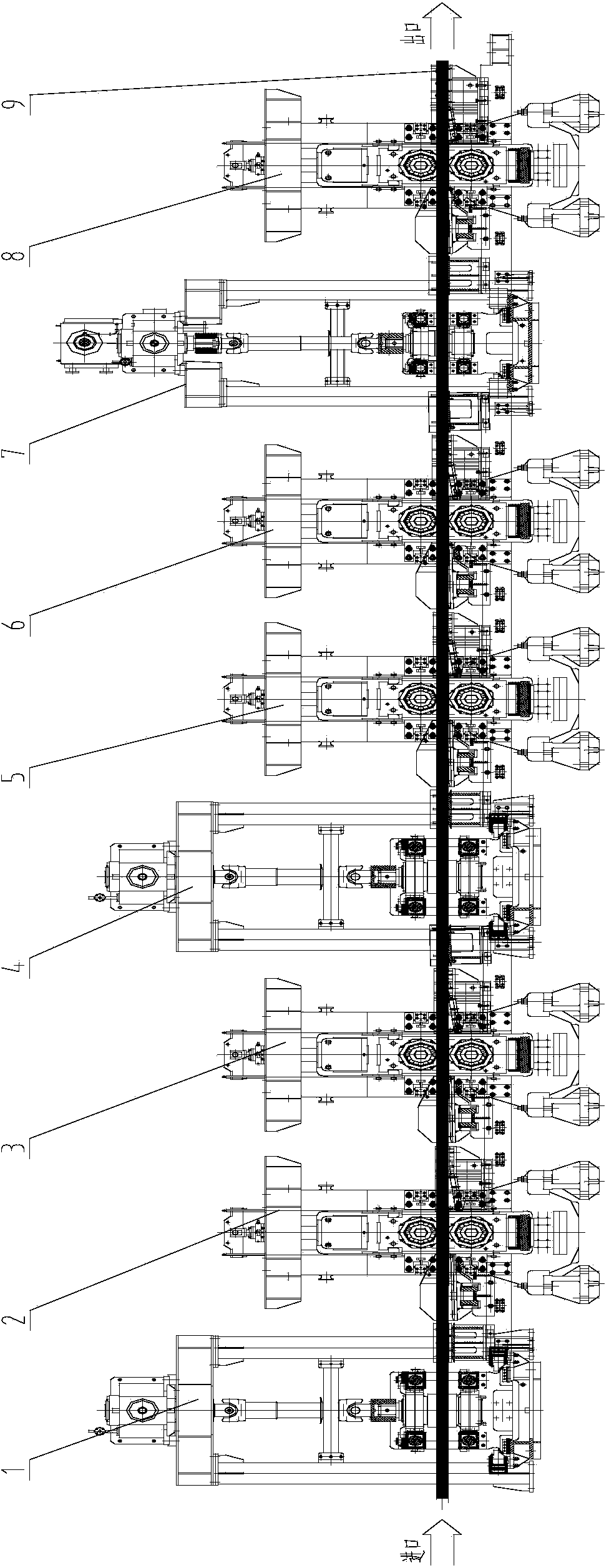

Tandem rolling process of roughing rolling unit

A technology of rough rolling unit and continuous rolling, which is applied in the direction of metal rolling, and can solve the problems of affecting the output of strip steel mills, large bearing capacity, and affecting processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The present invention is described now in conjunction with accompanying drawing, the continuous rolling process of roughing mill unit, and its process is:

[0023] The first process: The vertical rollers of the vertical rolling mill 1 carry out hot rolling on the original strip steel billet; the original strip steel blank heated to a temperature of 1100°C-1150°C is placed on the working table of the production line and placed on the In front of the vertical roller of vertical roller mill 1, the original strip steel blank is conveyed to the direction of the vertical roller of vertical roller mill 1, so that the vertical roller of vertical roller mill 1 bites into the original strip steel blank and performs width hot rolling on the original strip steel blank to form Strip steel blank 1, the width of the strip steel blank 1 is reduced by 40-50mm compared with the width of the original strip steel blank;

[0024] The second process: the flat roll of flat roll mill 1 carries...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com