Rotating disc type repair station for storing and maintaining coke oven doors and operation method

A repair station and turntable technology, applied in coke oven heating, coke oven door/closer, coke oven, etc., can solve the problem of low work efficiency, labor and time-consuming, and the furnace door repair station cannot receive the second furnace Doors and other problems can be solved to achieve the effect of saving land occupation and compact process layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

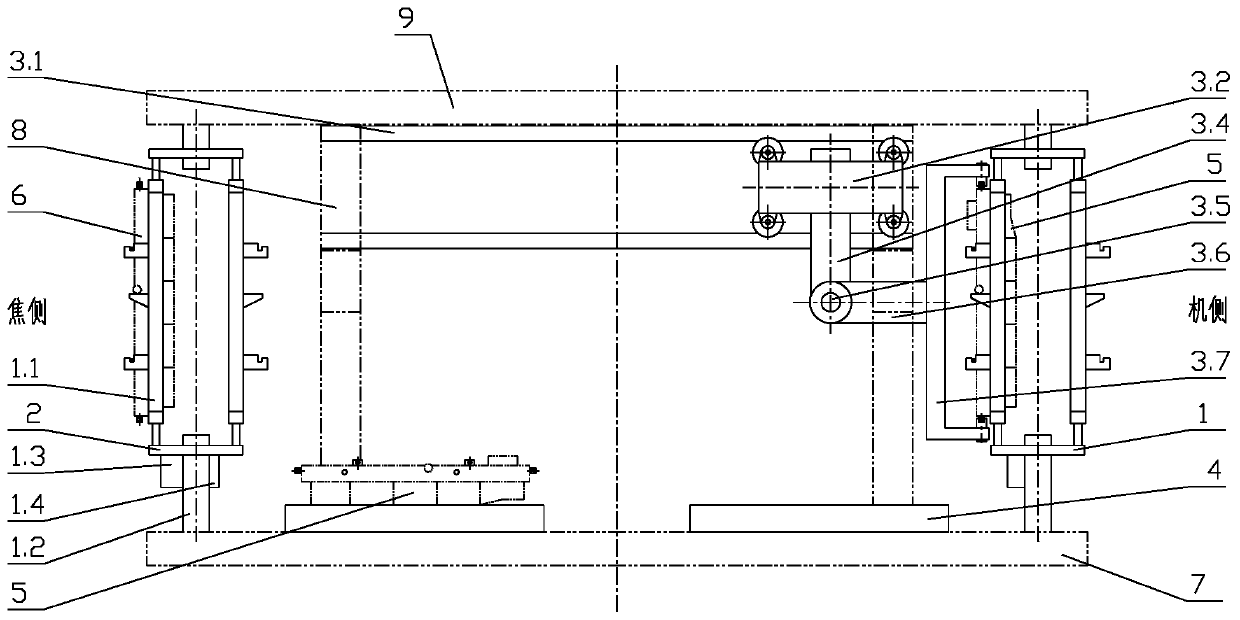

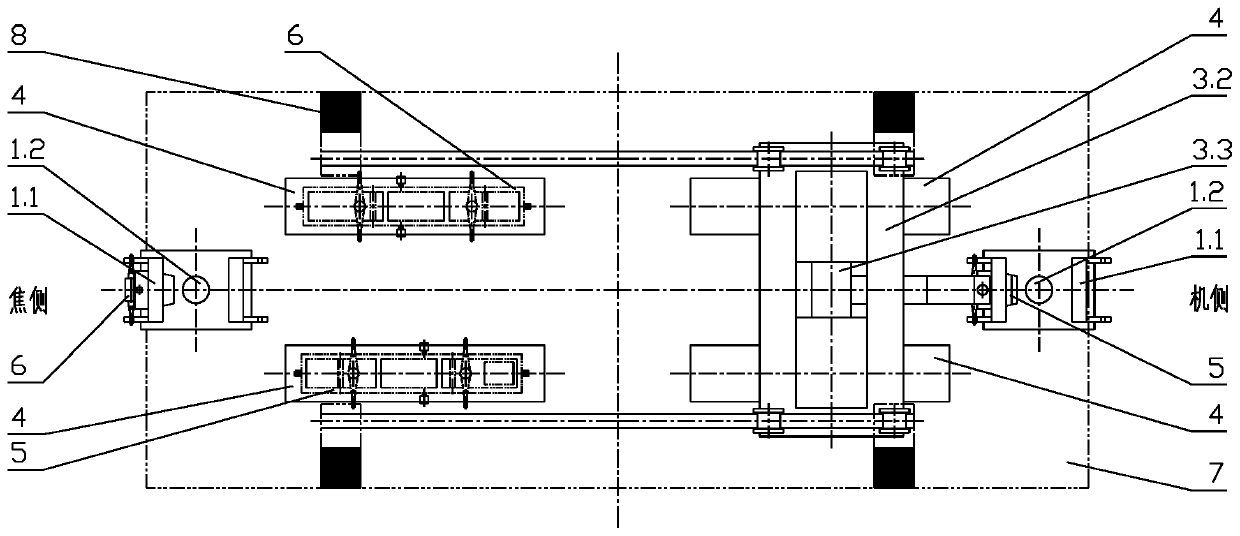

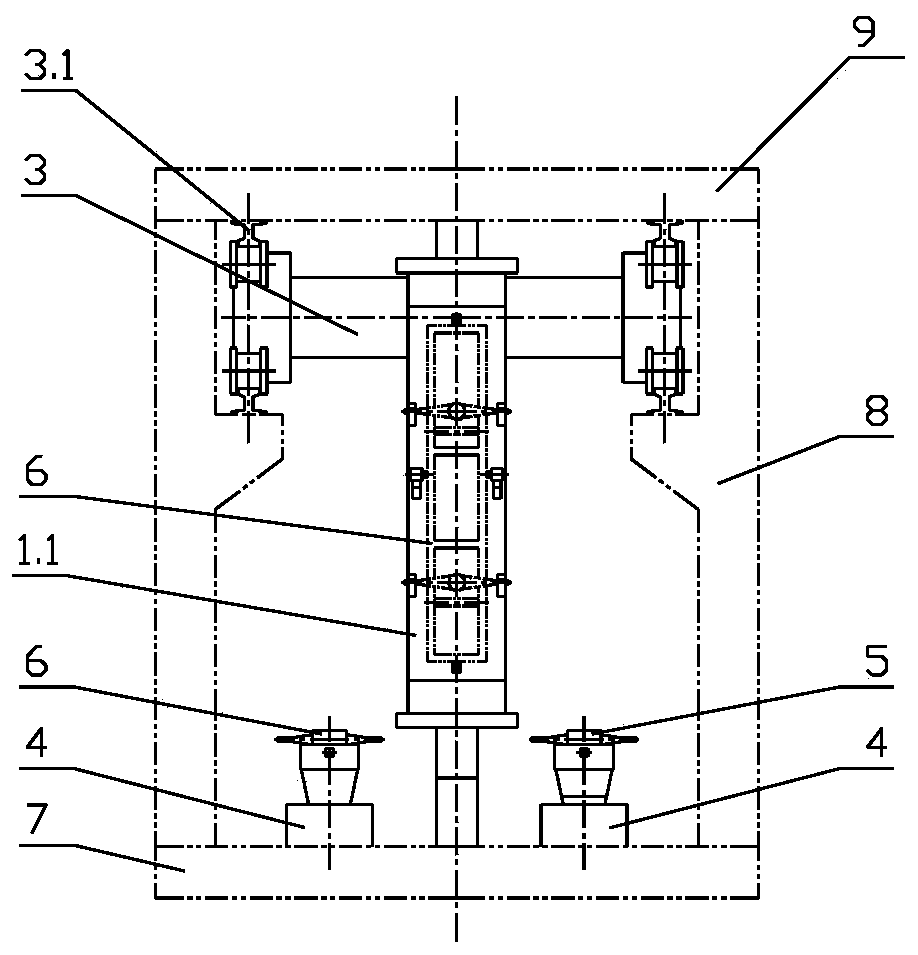

[0041] See Figure 1-Figure 3As shown, a carousel type repair station for storing and maintaining coke oven doors according to the present invention includes a carousel door repair station composed of machine-side storage carousel 1, coke-side storage carousel 2 and furnace door removal and hanging device 3 The machine-side storage carousel 1 is arranged on the machine side for storing the machine-side furnace door 5; the coke-side storage carousel 2 is arranged on the coke side for storing the coke-side furnace door 6; the machine-side storage carousel 1, coke There are multiple furnace door storage positions on the side storage carousel 2; a furnace door repair station 4 is provided in the middle of the furnace door repair station between the machine side storage carousel 1 and the coke-side storage carousel 2, and the furnace door lifting devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com