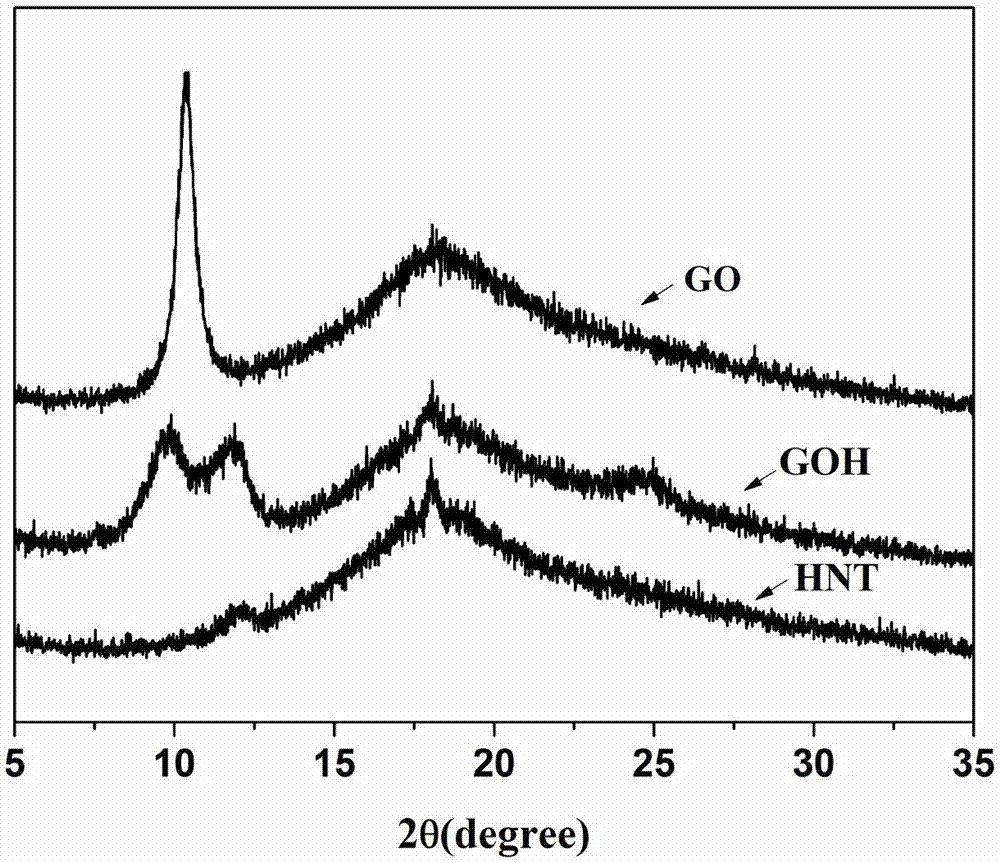

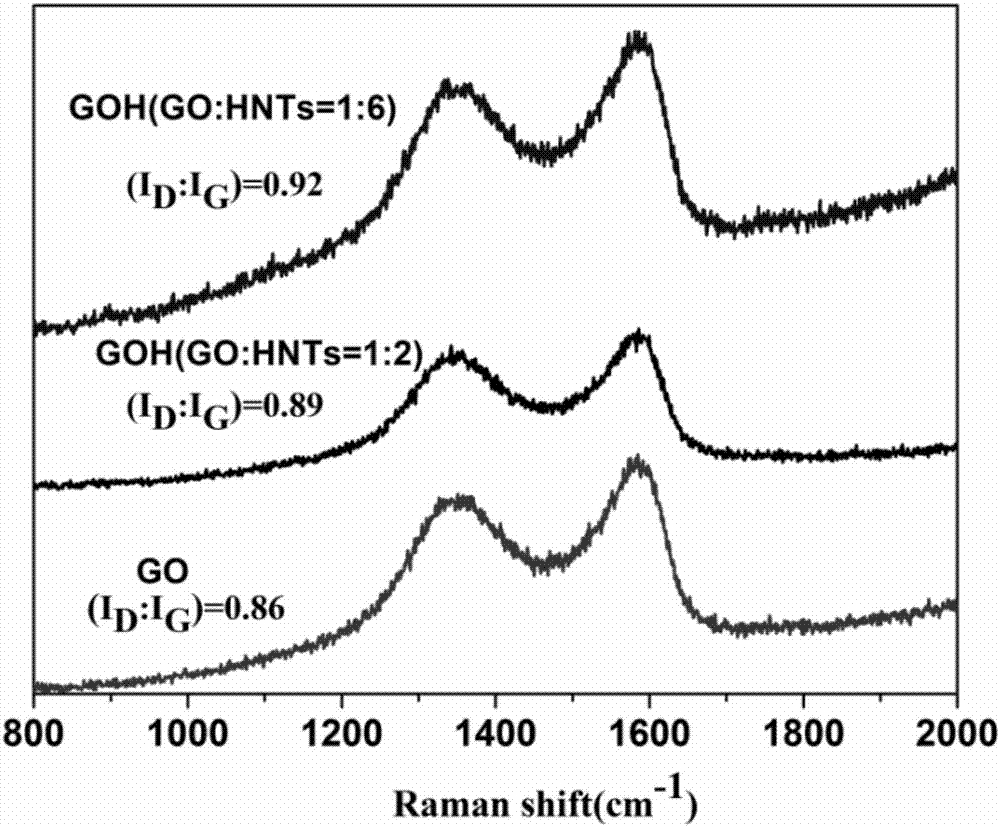

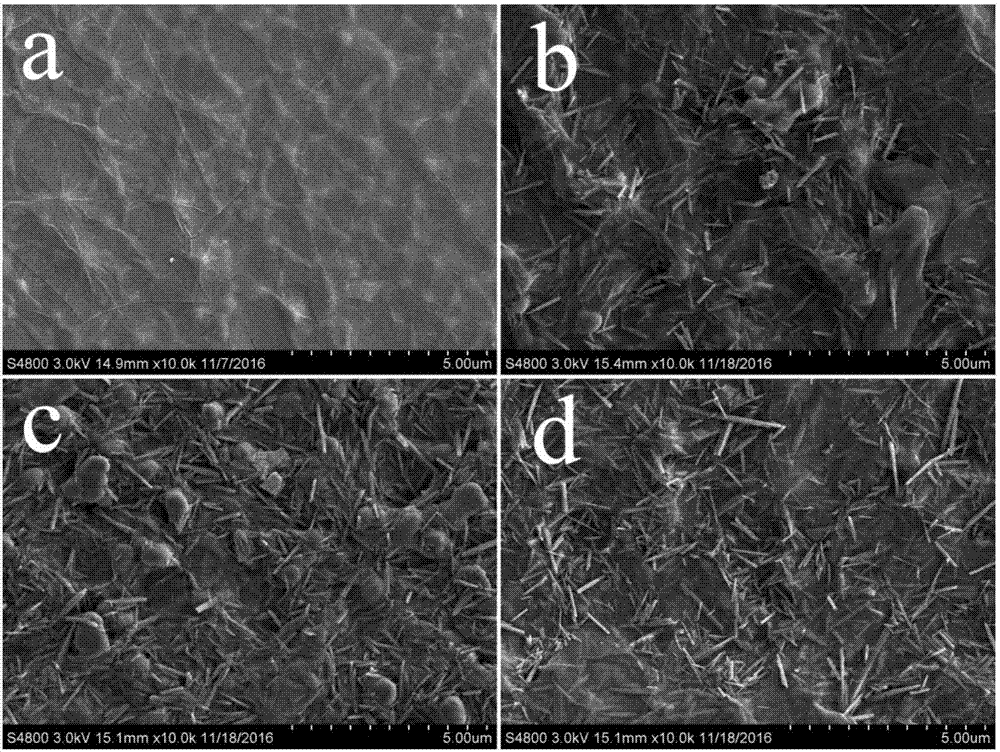

Preparing method of high-performance graphene oxide/halloysite nanotube composite water-oil separation film

A halloysite nanotube, water and oil separation technology, applied in the field of functional membranes, can solve problems such as poor anti-fouling performance, and achieve the effects of small structural damage, high oxidation degree, and low oxidation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment prepares graphene oxide / halloysite nanotube composite water-oil separation membrane according to the following steps:

[0036] 1. Preparation of sheet-layer graphene oxide

[0037] Mix 2g graphite powder with 1g NaNO 3 Add the powder into a three-necked flask, and then add 50 mL of concentrated H with a mass concentration of 98%. 2 SO 4 , with magnetic stirring in an ice-water bath, 6g KMnO 4The solid particles were added to the three-necked flask in batches at 5°C, and after the addition was completed, the temperature was raised to 35°C and stirred for 24 hours; after the reaction, 100mL of deionized water was added to the reaction solution, and 250mL of deionized water was added after mixing evenly, and then Add 15mL of 30wt% hydrogen peroxide dropwise to the reaction solution, then add 200mL of 1mol / L HCl solution, stir and mix evenly, then centrifuge at a speed of 4500r / min, remove the supernatant, wash with water and centrifuge the precipitate un...

Embodiment 2

[0044] In this embodiment, the graphene oxide / halloysite nanotube composite water-oil separation membrane is prepared according to the same method as in Example 1, the difference is only that the mass ratio of sheet-layer graphene oxide to halloysite nanotube is 1:4 in step 3, The obtained composite water-oil separation membrane is denoted as GOH (GO:HNTs=1:4).

Embodiment 3

[0046] In this embodiment, the graphene oxide / halloysite nanotube composite water-oil separation membrane is prepared according to the same method as in Example 1, the difference is only that the mass ratio of sheet-layer graphene oxide to halloysite nanotube is 1:6 in step 3, The obtained composite water-oil separation membrane is denoted as GOH (GO:HNTs=1:6).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com