Hollow fiber ultrafiltration membrane and preparation method thereof

An ultrafiltration membrane and fiber technology, applied in the field of membrane separation, can solve the problems of difficult cleaning and organic pollution, and achieve the effects of less pollution, high water flux, and high operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides the preparation method of above-mentioned hollow fiber ultrafiltration membrane, comprises the following steps:

[0042] 1) mixing the raw materials in the mass parts by mass to obtain the spinning casting solution;

[0043] 2) Extrude the spinning casting solution obtained in the step 1) to form a film, draw and solidify in sequence to obtain a nascent hollow fiber ultrafiltration membrane;

[0044] 3) The nascent hollow fiber ultrafiltration membrane obtained in the step 2) is soaked in water, glycerin aqueous solution and dried in sequence to obtain a hollow fiber ultrafiltration membrane.

[0045] In the invention, the raw materials in the mass parts are mixed to obtain the spinning casting liquid.

[0046] In the present invention, the mixing is preferably first mixed with lithium chloride, organic porogen and organic solvent to obtain the first mixed solution; then the first mixed solution is mixed with polym-phenylene isophtha...

Embodiment 1

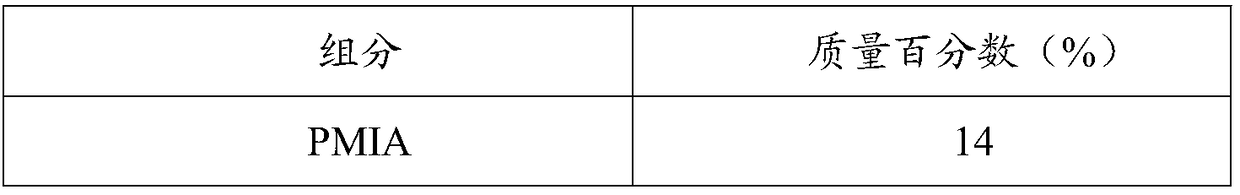

[0069] Raw material formula in the embodiment 1 of table 1

[0070] components

Mass percentage (%)

PMIAs

14

4

DMAC

82

[0071] 1) Add lithium chloride to N,N-dimethylacetamide solvent (DMAC), stir at 45°C to completely dissolve, then add poly-m-phenylene isophthalamide fiber (PMIA), at 6°C Stir for 4 hours to form a homogeneous solution to obtain a casting solution; pour the casting solution into a closed reaction kettle, and vacuum defoam to obtain a spinning casting solution;

[0072] 2) Filtrating the spinning casting solution through an iron mesh under 0.1MPa nitrogen pressure, extruding from a spinneret to form a film, evaporating, gravity pulling, and gel solidification to obtain a nascent hollow fiber ultrafiltration membrane.

[0073] 3) Soak the obtained nascent hollow fiber ultrafiltration membrane in pure water for 48 hours, then soak it in 50 wt% glycerin aqueous solution for 48 hours, and finally ta...

Embodiment 2

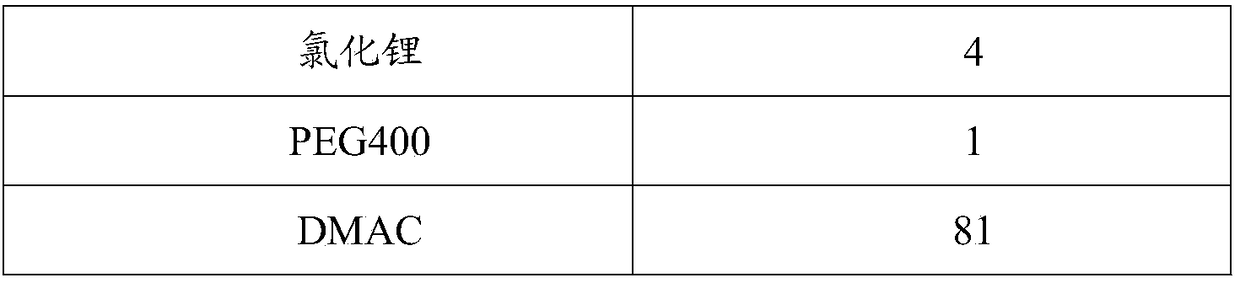

[0075] Raw material formula in table 2 embodiment 2

[0076]

[0077]

[0078] 1) Add lithium chloride and polyethylene glycol (PEG400) to N,N-dimethylacetamide solvent (DMAC), stir and dissolve completely at 60°C, then add polym-phenylene isophthalamide Fiber, stirred at 80°C for 4 hours to form a homogeneous solution to obtain a casting solution; pour the casting solution into a closed reaction kettle, and vacuum defoam to obtain a spinning casting solution;

[0079] 2) Filtrating the spinning casting solution through an iron mesh under 0.3MPa nitrogen pressure, extruding from a spinneret to form a film, evaporating, pulling, and gel curing to obtain a nascent hollow fiber ultrafiltration membrane.

[0080] 3) Soak the obtained nascent hollow fiber ultrafiltration membrane in pure water for 45 hours, then soak it in 50 wt% glycerol aqueous solution for 50 hours, and finally take out the wet ultrafiltration membrane and dry it to obtain a hollow fiber ultrafiltration me...

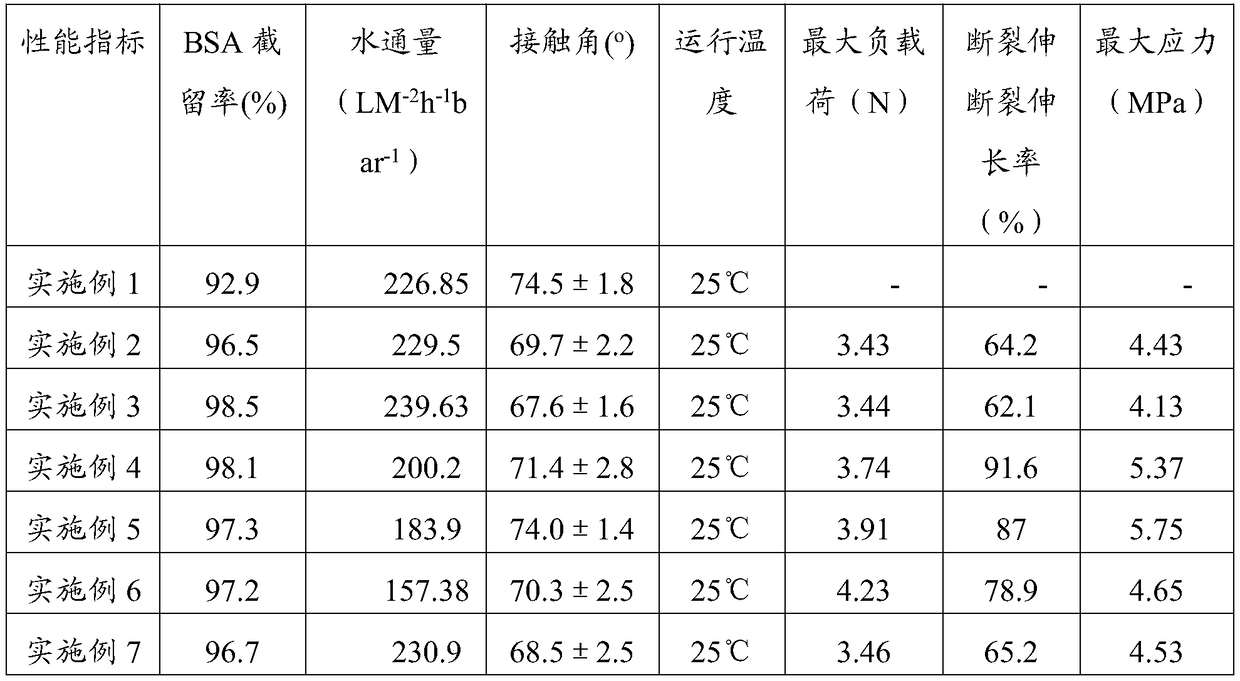

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface contact angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com