Measurement method for reverse backflow amount of vapor generator heat conduction tube and system of measurement method

A steam generator and measurement system technology, applied in reactors, nuclear power generation, nuclear reactor monitoring, etc., can solve the problems of difficult backflow flow measurement, complex steam generator structure, and insufficient installation space, so as to avoid insufficient space and structural damage , good use prospects and market application value, and the effect of reducing technical difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

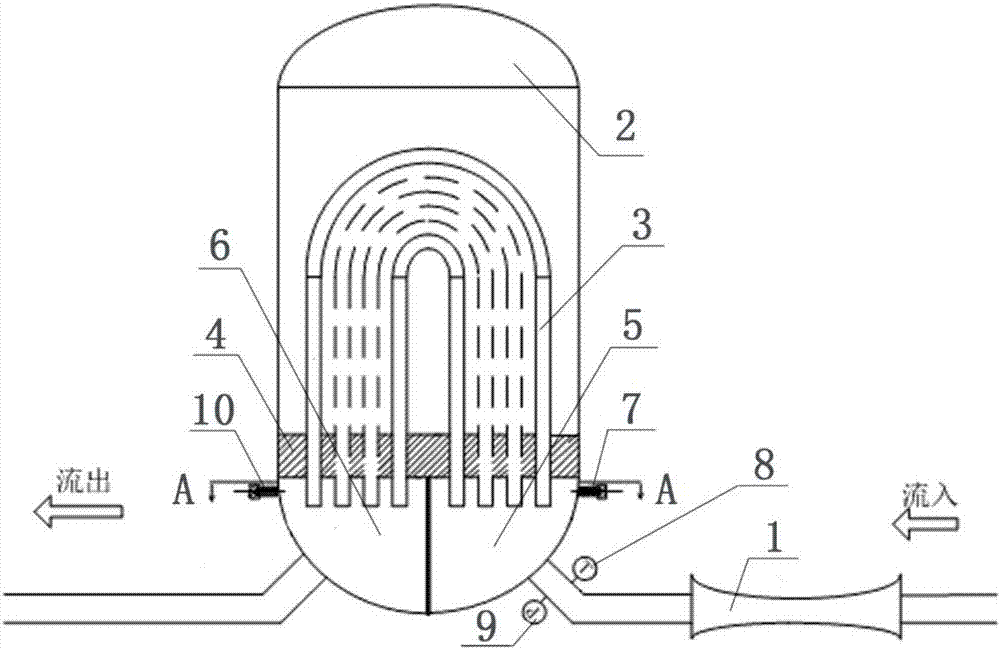

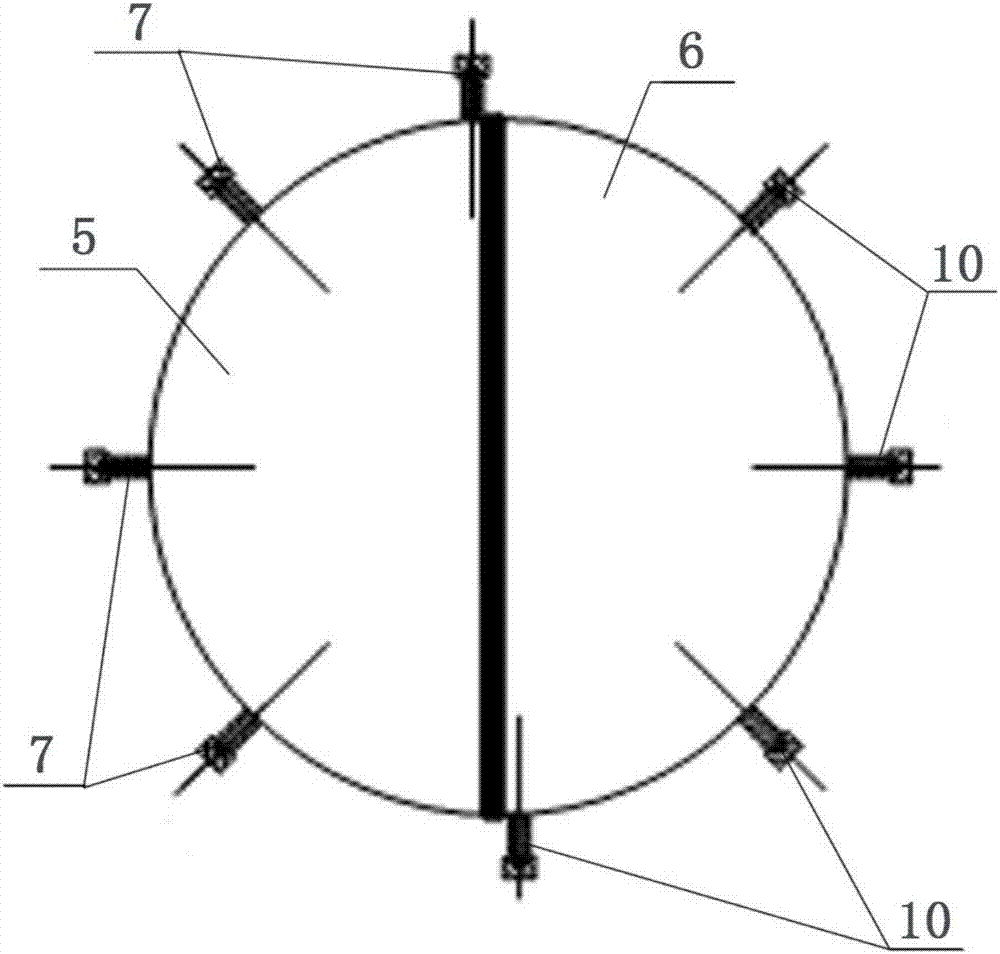

[0039] A measurement system for reverse and reverse flow of steam generator heat transfer tubes, such as figure 1 As shown, it includes a flow meter 1 , an inlet temperature measuring device 8 , an inlet pressure measuring device 9 , an inlet chamber temperature measuring device 7 , and an outlet chamber temperature measuring device 10 .

[0040] The measurement system of the present invention is applied to a U-shaped tube steam generator, wherein the U-shaped tube steam generator includes a primary side and a secondary side 2 . According to the flow direction, the primary side is followed by an inlet chamber 5, a U-shaped heat transfer tube bundle 3 and an outlet chamber 6. The U-shaped heat transfer tube bundle 3 is fixed on the tube sheet 4 in the steam generator, and the inlet chamber 5 and the outlet chamber The front and rear ends of the chamber 6 are respectively connected with the inlet pipe and the outlet pipe of the steam generator. The secondary side 2 of the steam...

Embodiment 2

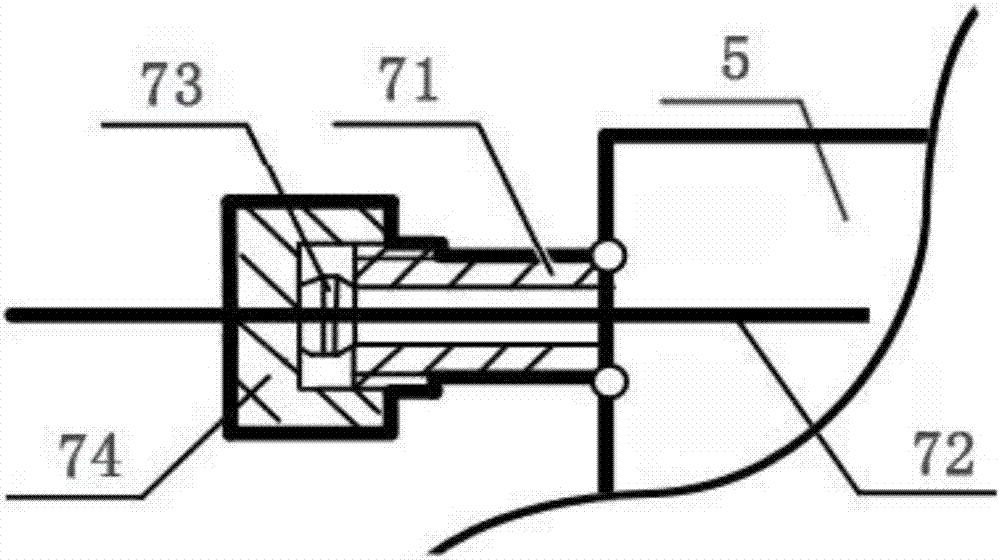

[0050] The difference between this embodiment and Embodiment 1 is that this embodiment provides the structure of the optimized inlet chamber temperature measuring device 7, which includes a temperature measuring assembly 71, a thermocouple 72, a sealing pad 73 and hold-down nut 74, concrete settings are as follows:

[0051] The front end of the temperature measuring component 71 is welded on the pipe wall on the primary side of the steam generator, and the rear end is sealed by a gasket 73 and a compression nut 74 . A through hole is opened on the pipe wall at the position of the welding temperature measuring assembly 71, and a through hole corresponding to the through hole on the pipe wall is set on the temperature measuring assembly 71 at the same time, and the thermocouple 72 passes through the temperature measuring assembly 71 and the through hole on the pipe wall. The hole is inserted into the fluid to be tested on the primary side of the steam generator for temperature m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com