Combine harvester grain loss sensor performance calibration device

A technology of combine harvester and calibration device, which is applied to harvesters, cutters, instruments, etc., can solve the problems of low grain loss detection efficiency, loss, and uncontrolled number of grains thrown down, so as to improve detection efficiency and work stability. performance, optimize design, and improve the efficiency of loss detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

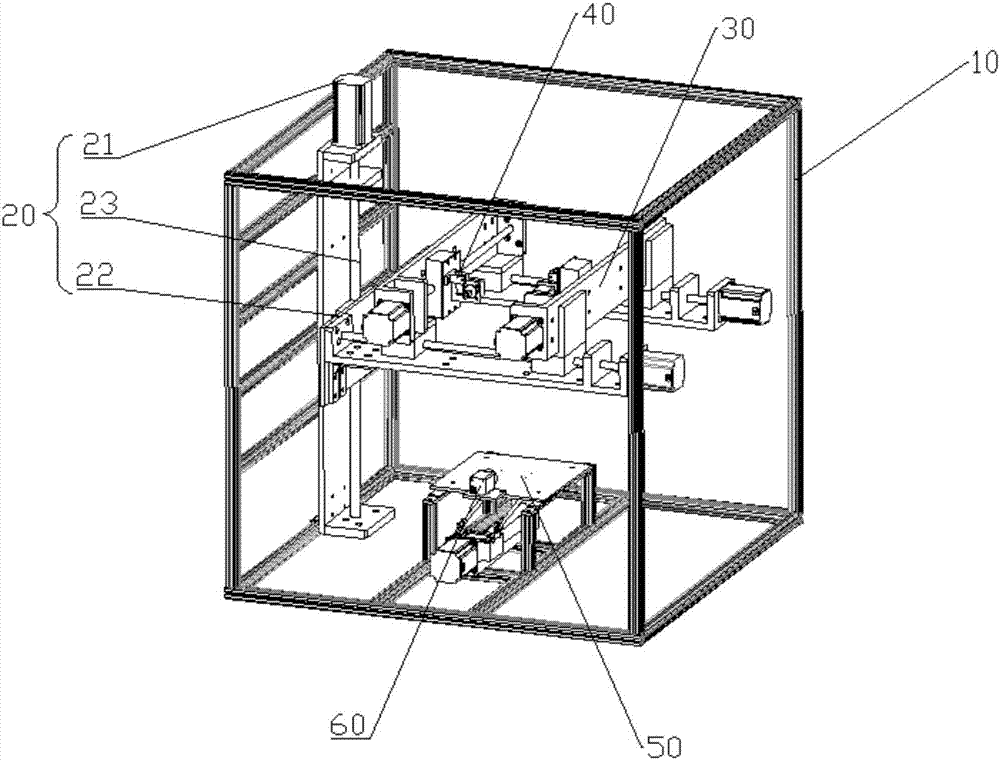

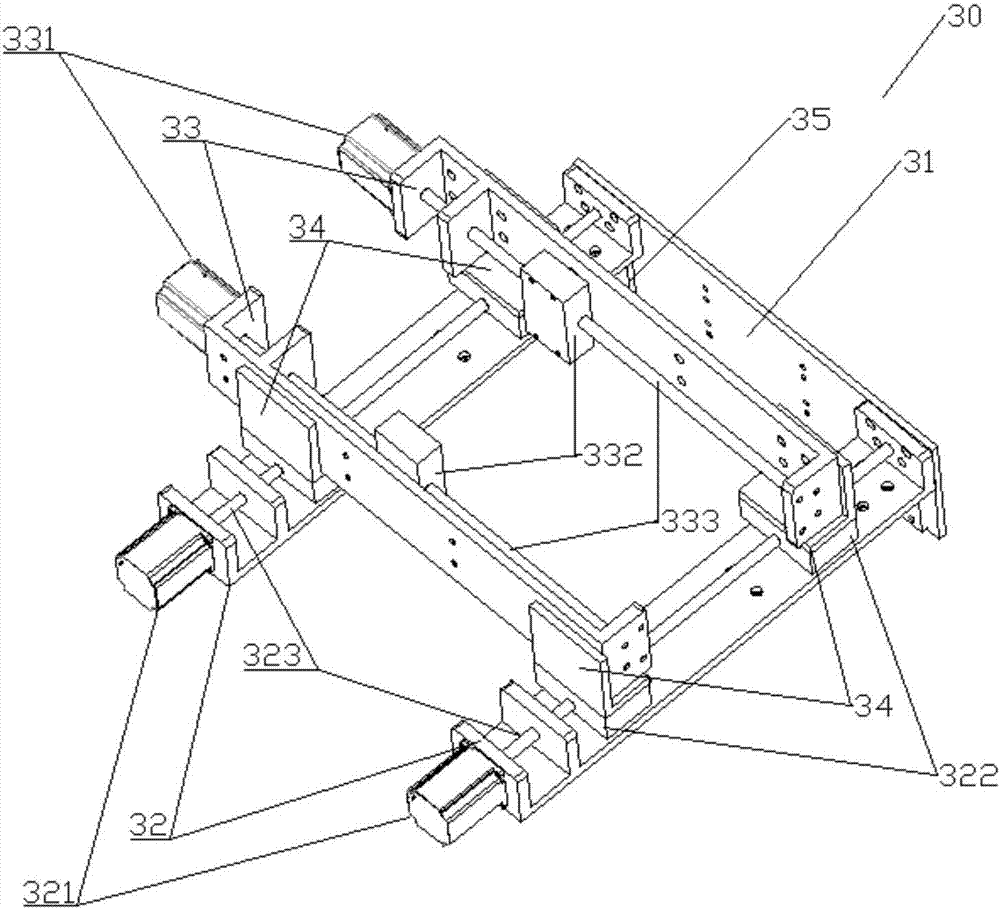

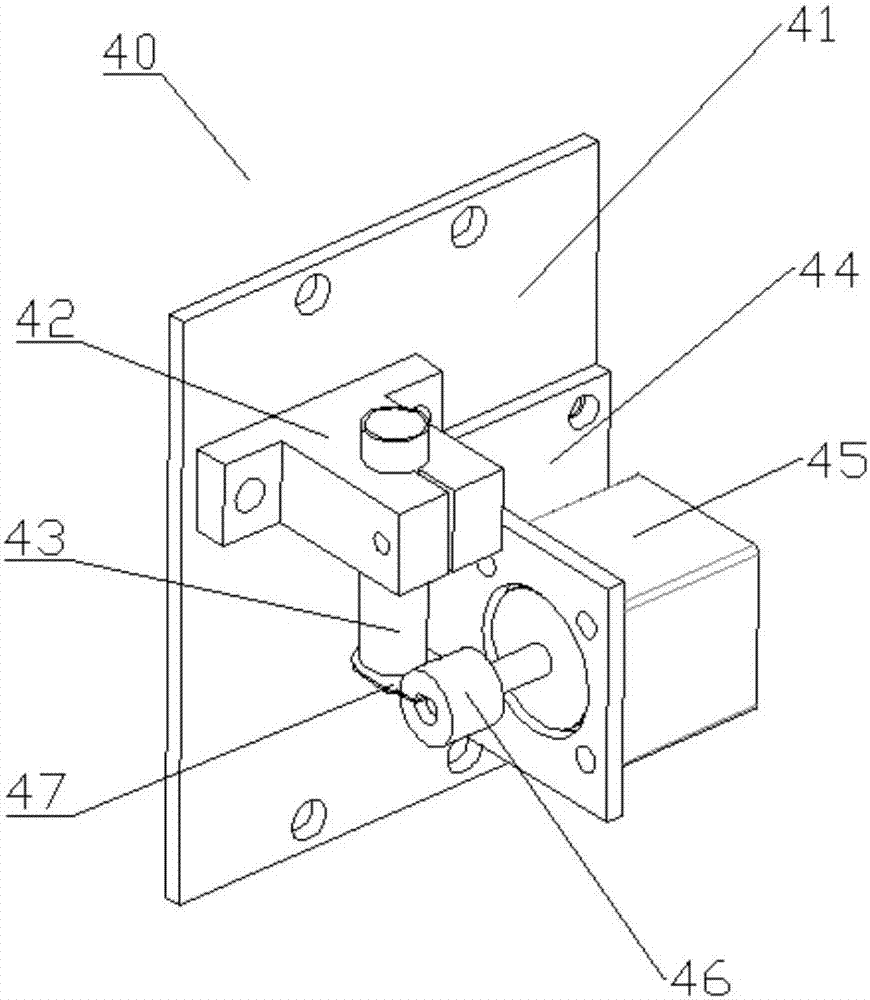

[0029] Such as figure 1 As shown, the specific implementation of the present invention comprises support frame 10, lifting mechanism 20, moving platform 30, drop seed assembly 40, sensor support platform 50, camera assembly 60, control system 70; Support frame 10 is placed vertically, and sensor support platform 50 and The lifting mechanism 20 is all fixed on the support frame 10, and the lifting mechanism 20 is connected with the moving platform 30 positioned at the top of the sensor supporting platform 50. The moving platform 30 is equipped with a falling seed assembly 40, and the camera assembly 60 is installed on the sensor supporting platform 50. The control system 70 is respectively connected with the lifting mechanism 20, the moving platform 30, the seed dropping assembly 40, the sensor supporting platform 50 and the camera ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com