A functional material with latent heat regulation and passive humidity regulation, its preparation method and application

A functional material and mild technology, applied in the field of building materials, can solve the problems of inability to achieve temperature regulation at the same time, lack of complementary materials with different pore sizes, and limited range of humidity regulation, so as to enhance heat storage capacity and heat capacity, and widen humidity regulation. Range, thermal conductivity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

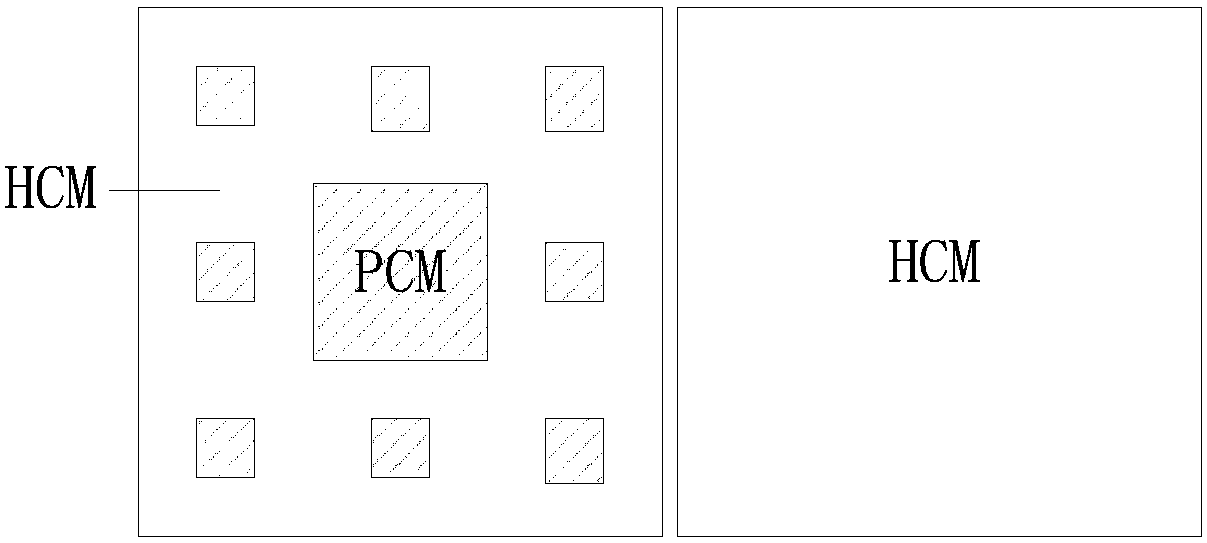

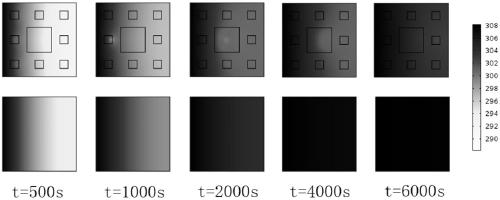

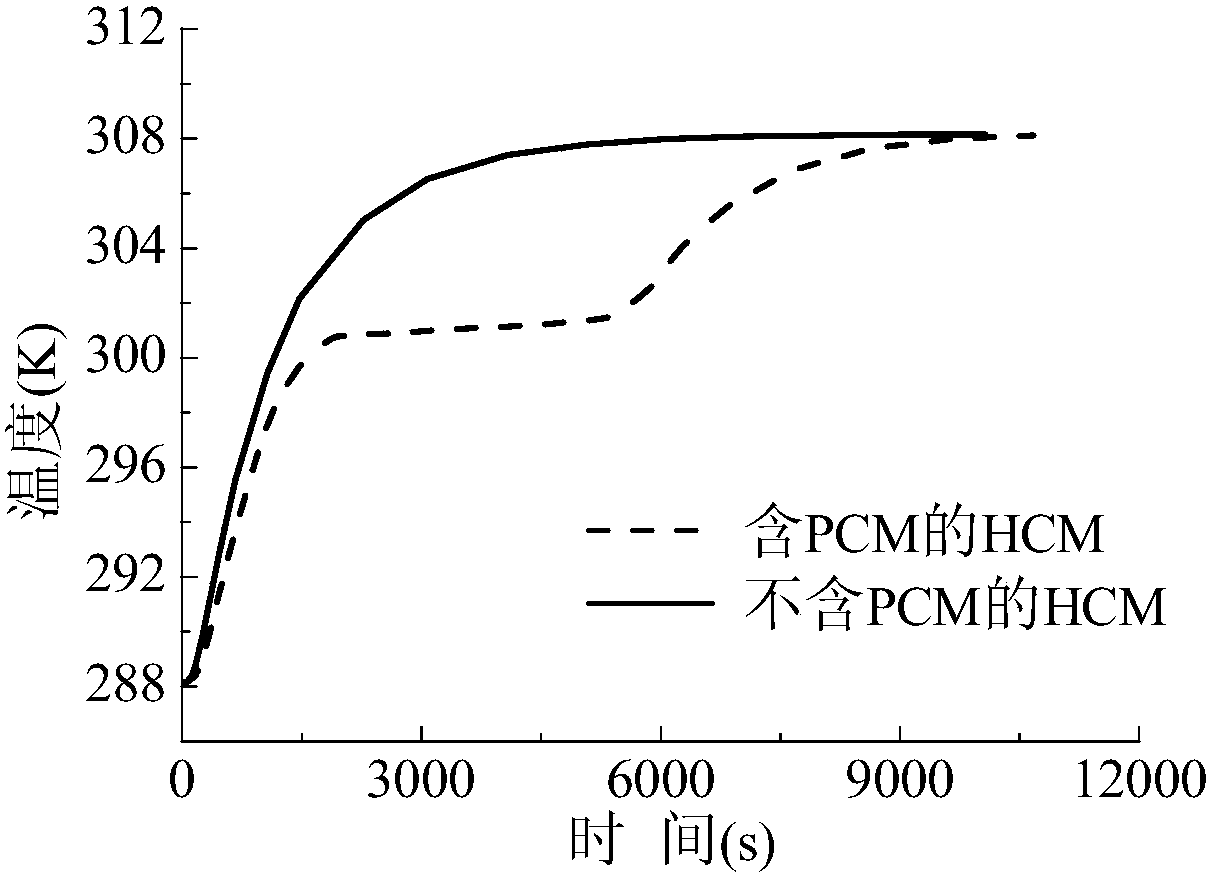

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the above-mentioned functional material with latent heat regulation and passive humidity regulation, the specific steps are as follows:

[0048] Step 1, pretreatment of diatomite: refer to the method disclosed in Chinese patent 201110445847.7 to pretreat diatomite, that is, calcining diatomite at a high temperature of 500-800°C for 1-8 hours;

[0049] Step 2, preparation of composite phase-change capsules: the solid paraffin and liquid paraffin are prepared in a ratio of 5 to 8 parts by mass: 3 parts to prepare a binary mixture, and the binary mixture and expanded graphite are in a mass ratio of 100 parts: 1 to 4 parts Mix the ratio of the composite phase change core material with a phase change temperature of 22-29°C. After the composite phase change core material is solidified into solid particles, stir the solid particles and water-based epoxy resin at a mass ratio of 5:1 , so that the epoxy resin is fully coated on the surface of the solid ...

Embodiment 1

[0052] A functional material with latent heat regulation and passive humidity regulation, wherein the mass ratio of each component is: 30 parts of 32.5 type cement, 15 parts of calcined diatomite, 5 parts of poplar wood powder, and 15 parts of pulverized coal Ash, 10 parts of composite phase change capsules, 15 parts of light sludge ceramsite, 5 parts of corn starch glue stabilizer, 2 parts of nano-titanium dioxide antibacterial agent, 2 parts of OBPA antifungal agent antifungal agent, 130 parts water.

[0053] A method for preparing a functional material with latent heat regulation and passive humidity regulation, the specific steps are:

[0054] Step 1, pretreatment of diatomite: calcining diatomite at a high temperature of 500° C. for 3 hours;

[0055] Step 2, preparation of composite phase change capsules: prepare a binary mixture with solid paraffin and liquid paraffin at a mass ratio of 8:3, mix the binary mixture with expanded graphite at a mass ratio of 100:4, and pre...

Embodiment 2

[0061] A functional material with latent heat regulation and passive humidity regulation, wherein the mass ratio of each component is: 25 parts of 32.5 type cement, 20 parts of calcined diatomite, 5 parts of poplar wood powder, and 17 parts of pulverized coal Ash, 18 parts of composite phase change capsules, 15 parts of light sludge ceramsite, 4 parts of corn starch glue stabilizer, 3 parts of nano-titanium dioxide antibacterial agent, 3 parts of OBPA antifungal agent antifungal agent, 140 parts water.

[0062] The preparation method of the functional material with latent heat regulation and passive humidity regulation in this example is different from Example 1 in that: solid paraffin and liquid paraffin are prepared in a ratio of 6.5:3 by mass to a binary mixture, and the binary mixture and the expansion Graphite was mixed at a mass ratio of 100:3, and the phase transition temperature of the prepared composite phase change core material was 24.1-28°C, and the others were the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com