System and method for continuously treating domestic sludge

A technology for domestic sludge and sludge, which is used in pyrolysis treatment of sludge, dewatering/drying/concentrated sludge treatment, special forms of dry distillation, etc. Problems such as long-term continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

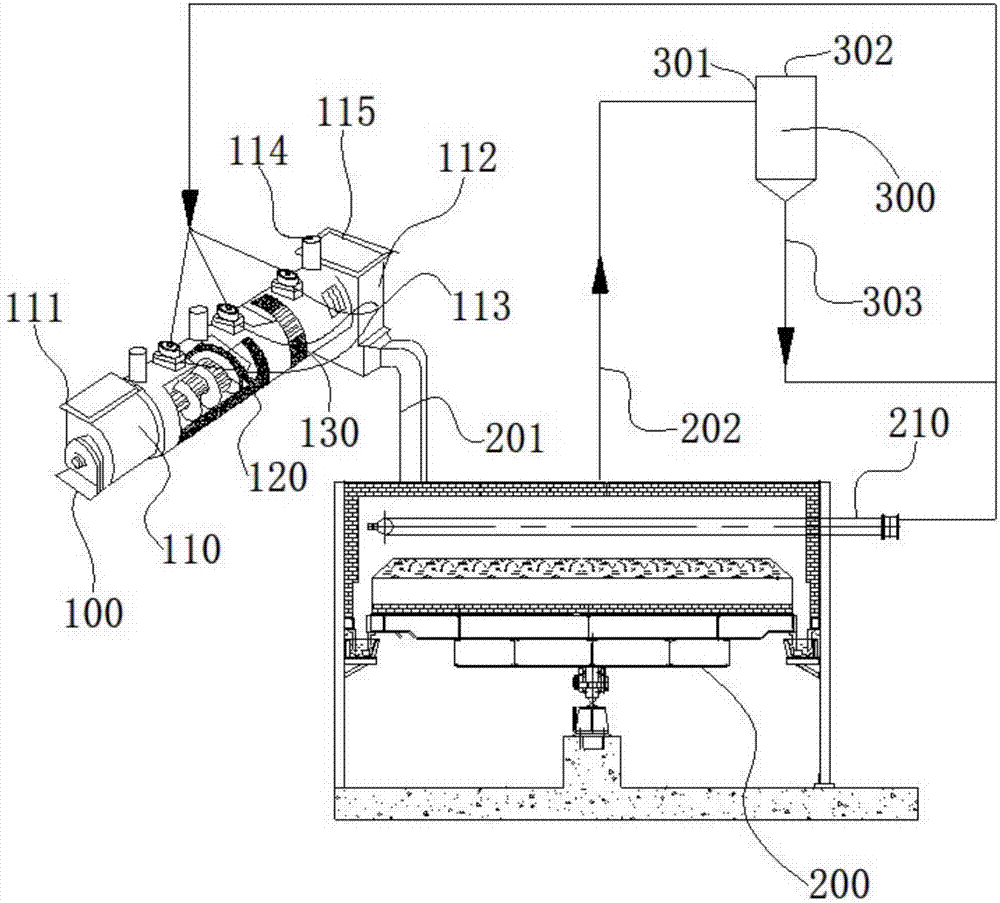

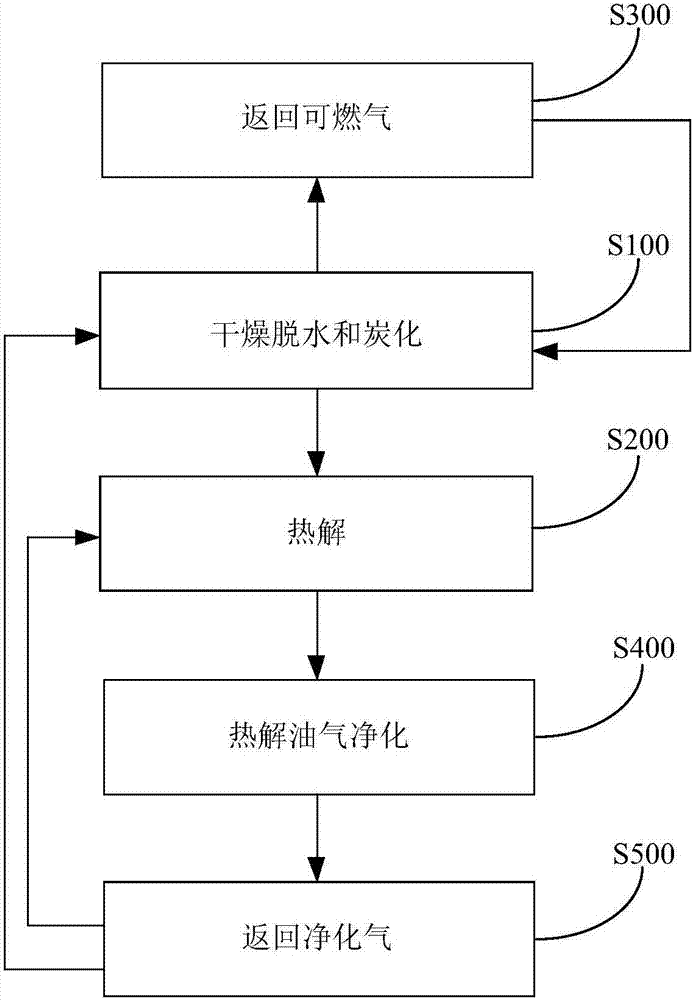

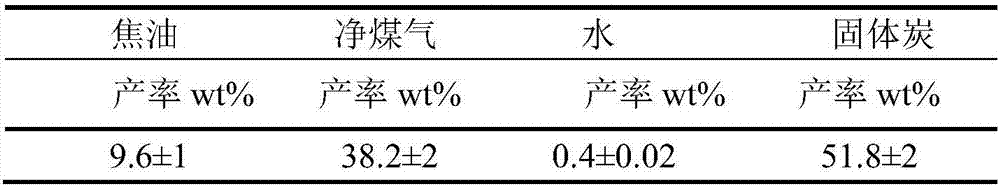

[0085] The domestic sludge with a water content of 82wt% is provided by the Beijing area. The material is stored in the silo, and the stones with a particle size > 30mm are firstly removed by a filter. The domestic sludge is fed into the feeding bin at the front end of the spiral drying carbonization furnace by the feeding system, and the domestic sludge enters the feeding area at the front end of the spiral drying carbonization furnace under the action of gravity. The sludge is sent into the spiral drying carbonization furnace, and the hot flue gas with a temperature of 220±20°C is generated by burning the burners below and above the screw conveyor to directly heat the domestic sludge, and the temperature of the surface domestic sludge near the combustion zone rises rapidly. High, the water evaporates quickly, the combustion heat is quickly transferred from the sludge surface to the inner layer, and under the agitation of the spiral, the domestic sludge is evenly disturbed, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com