Ortho-aminophenol wastewater treatment and recycling method

A technology for o-aminophenol and wastewater treatment, applied in water/sewage treatment, chemical instruments and methods, special compound water treatment, etc. problem, to achieve the effect of continuous production process, low production cost and high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

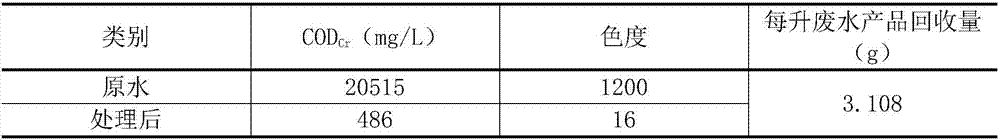

Embodiment 1

[0024] The present embodiment o-aminophenol waste water treatment and resource recovery method, carry out according to the following steps:

[0025] 1. Wastewater pretreatment: adjust the pH value of o-aminophenol wastewater to 7.5 with sulfuric acid or sodium hydroxide, and filter;

[0026] 2. Resin activation: at 60°C, successively use 1.5BV of 8% H 2 SO 4 and 8% NaOH are circulated for 2 hours respectively, and the circulating liquid is drained;

[0027] 3. Resin adsorption: pass the filtrate in step 1 into a resin column filled with G2 resin for adsorption. The resin processing capacity of G2 resin is 200BV, and the processing speed is 2BV / h;

[0028] 4. Advanced treatment: adjust the pH value of the filtrate absorbed by the resin column in step 3 to 3 with concentrated sulfuric acid, add iron filings to aerate the reaction for 4 hours, adjust the pH value of the micro-electrolyzed water to 7, filter, and adjust the pH value of the filtrate value to 4, add FeSO 4 and h...

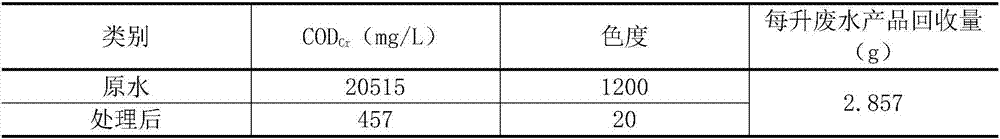

Embodiment 2

[0036] The present embodiment o-aminophenol waste water treatment and resource recovery method, carry out according to the following steps:

[0037] 1. Wastewater pretreatment: adjust the pH value of o-aminophenol wastewater to 8 with sulfuric acid or sodium hydroxide, and filter;

[0038] 2. Resin activation: at 60°C, successively use 1.5BV of 8% H 2 SO 4 and 8% NaOH are circulated for 2 hours respectively, and the circulating liquid is drained;

[0039] 3. Resin adsorption: pass the filtrate in step 1 into a resin column filled with G2 resin for adsorption. The resin processing capacity of G2 resin is 200BV, and the processing speed is 2-2.5BV / h;

[0040] 4. Advanced treatment: adjust the pH value of the filtrate absorbed by the resin column in step 3 to 3 with concentrated sulfuric acid, add iron filings to aerate the reaction for 4 hours, adjust the pH value of the micro-electrolyzed water to 7, filter, and adjust the pH value of the filtrate value to 3, adding Fe(NO 3...

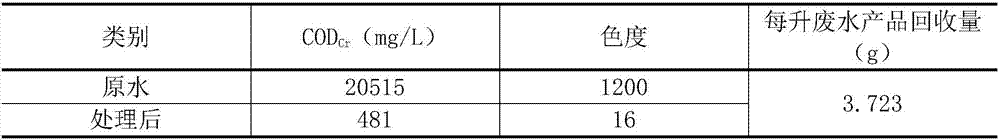

Embodiment 3

[0048] The present embodiment o-aminophenol waste water treatment and resource recovery method, carry out according to the following steps:

[0049] 1. Wastewater pretreatment: adjust the pH value of o-aminophenol wastewater to 8 with sulfuric acid or sodium hydroxide, and filter;

[0050] 2. Resin activation: at 60°C, successively use 1.5BV of 8% H 2 SO 4 and 8% NaOH are circulated for 2 hours respectively, and the circulating liquid is drained;

[0051] 3. Resin adsorption: pass the filtrate in step 1 into a resin column filled with G2 resin for adsorption. The resin processing capacity of G2 resin is 200BV, and the processing speed is 2BV / h;

[0052] 4. Advanced treatment: adjust the pH value of the filtrate absorbed by the resin column in step 3 to 3 with concentrated sulfuric acid, add iron filings for aeration reaction for 4 hours, adjust the pH value of the micro-electrolysis water to 8, filter, and adjust the pH value of the filtrate value to 3, add FeCl 2 and hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com