Flame retardant components for lithium batteries based on antimony nanomaterials

A nanomaterial and lithium battery technology, applied in the field of flame retardant film, can solve the problems of spontaneous combustion and explosion of consumers' lives and property safety, and achieve the effects of lowering temperature, improving flame retardant performance, and improving flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

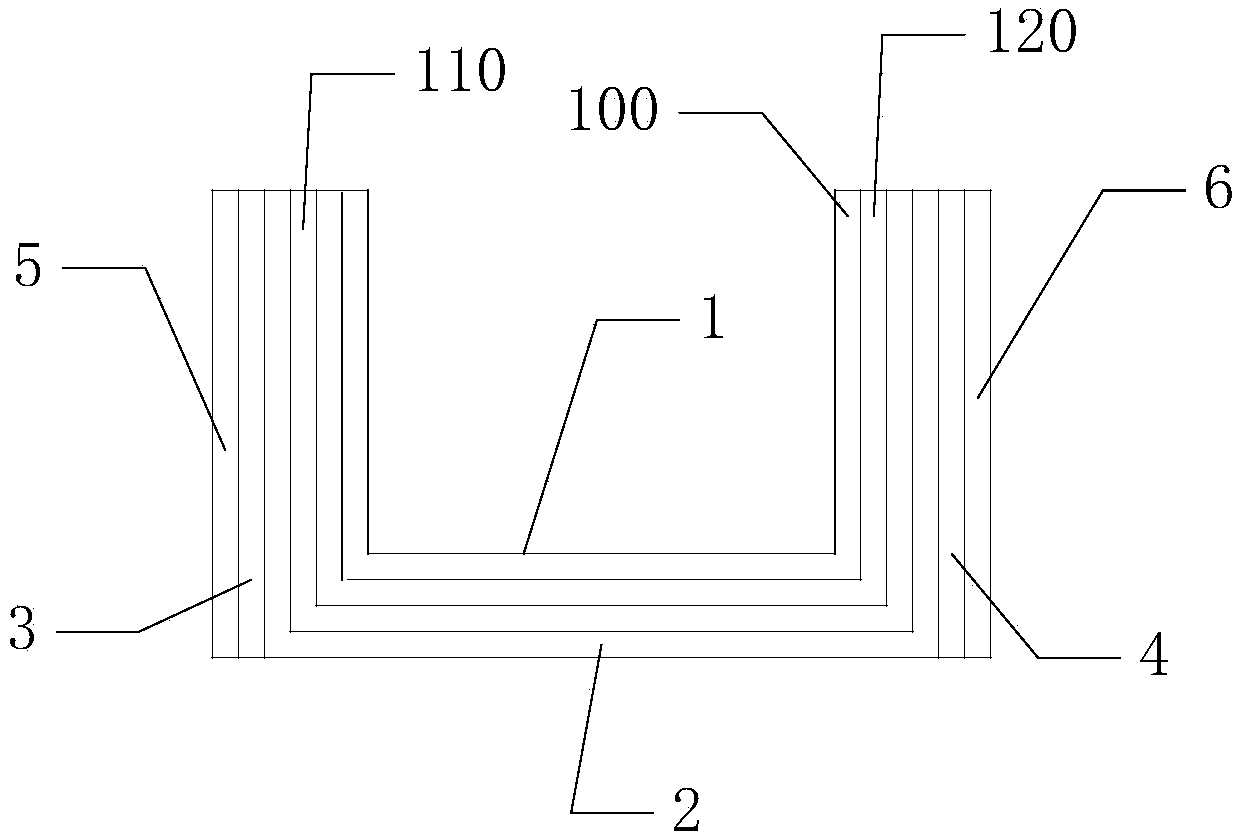

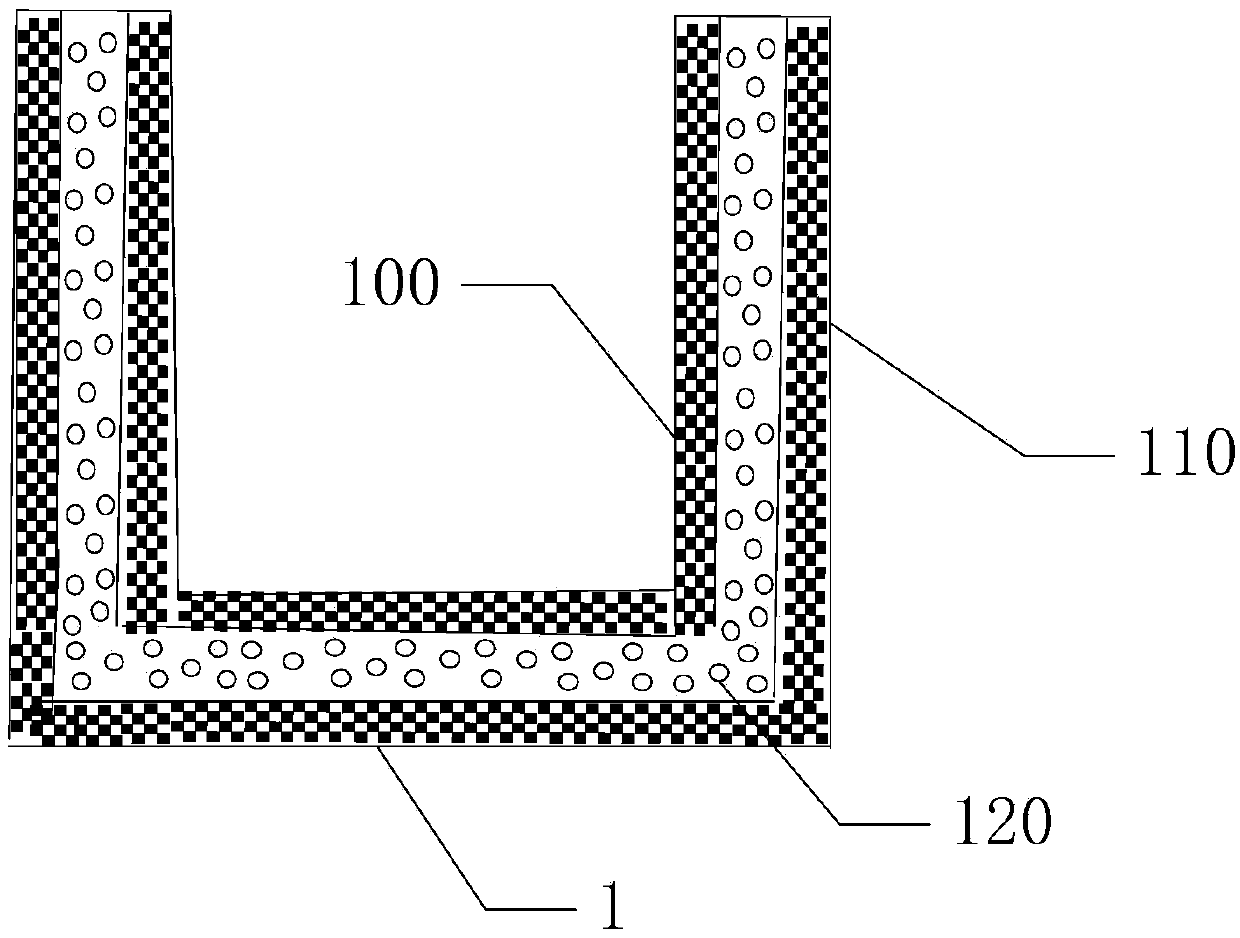

[0033] figure 1 and figure 2 The antimony nanomaterial-based lithium battery flame-retardant member provided by the present invention is shown, specifically including:

[0034] Porous membrane layer 1, which is a concave structure, said porous membrane layer 1 comprises a first porous membrane layer 100 and a second porous membrane layer 110, said first porous membrane layer 100 and said second porous membrane layer The layer 110 forms a cavity structure, and the thickness of the void 120 in the cavity structure is 0.1-0.25 μm, and the void 120 is filled with a heat-conducting medium;

[0035] A base film layer 2, which is attached to the second porous film layer, wherein the structure of the base film layer 2 matches the porous film layer 1, and is also a concave structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com