Air door lock block press-mounting tool

A technology for press-fitting tooling and valve locks, which is used in manufacturing tools, hand-held tools, etc., can solve the problems of high compression resistance of valve springs, easy fatigue, and inconvenient operation, and achieves high versatility. Improve the effect of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

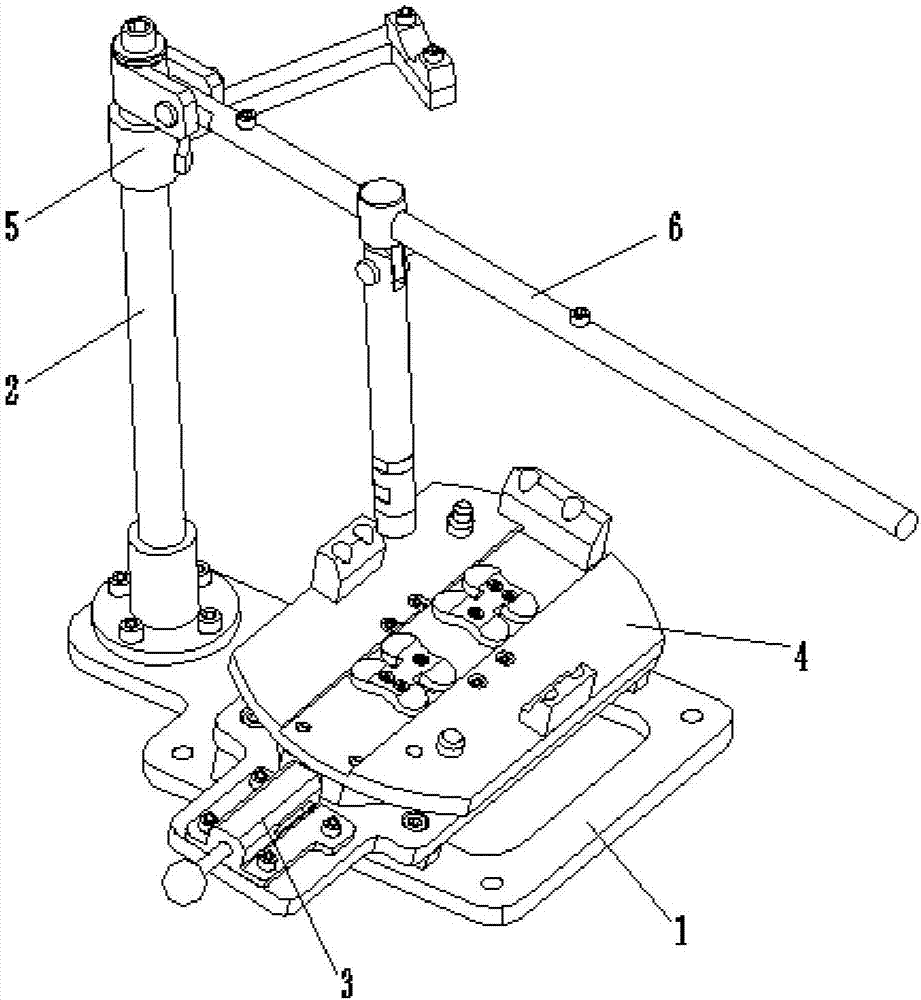

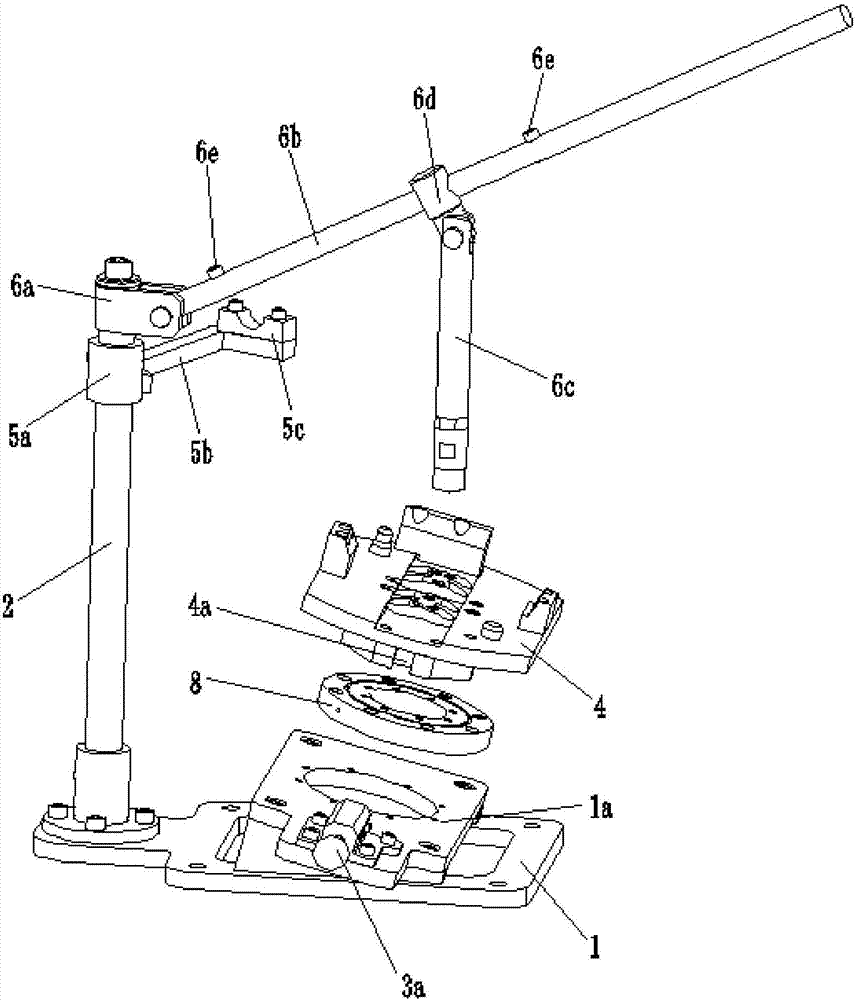

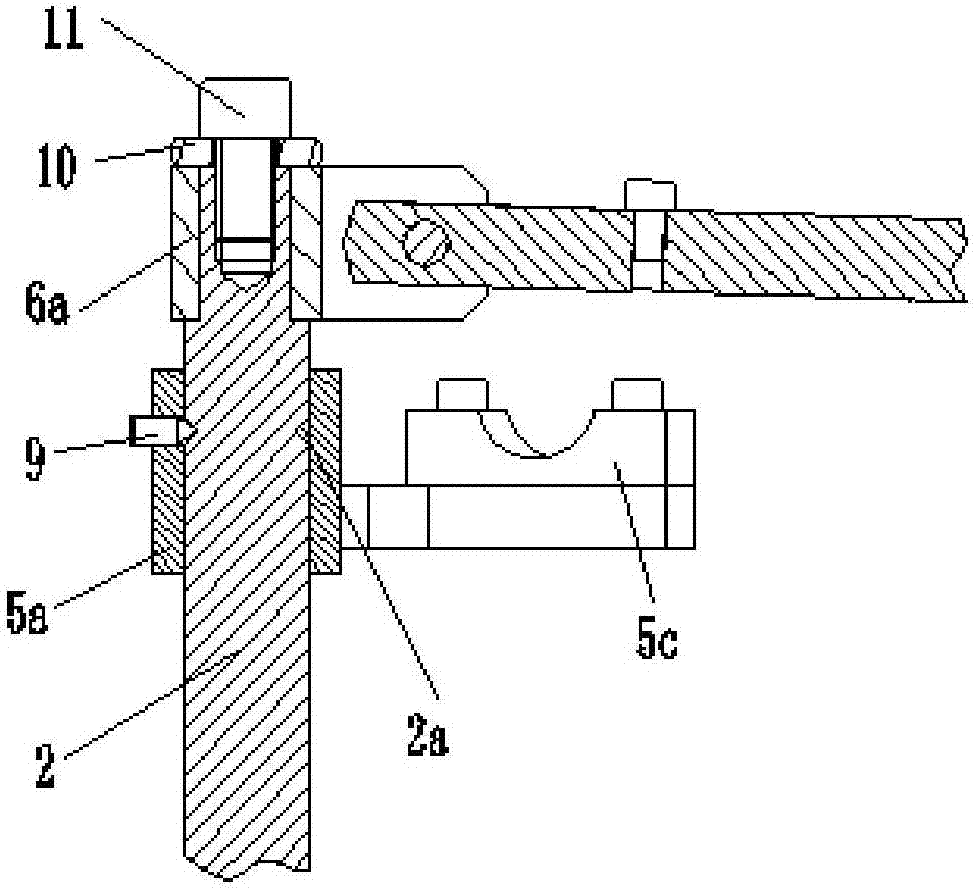

[0024] combine figure 1 — image 3 As shown, a valve lock block press-fitting tool is mainly composed of a bottom plate 1, a column 2, a turntable locking mechanism 3, a turntable assembly 4, a pressure rod support assembly 5, a pressure rod assembly 6, a cross ball collar 7, and a bearing mounting plate 8. Cone end set screw 9, washer 10 and screw 11 are composed.

[0025] Column 2, turntable locking mechanism 3, and turntable assembly 4 are installed on the base plate 1, and turntable assembly 4 is arranged obliquely and can rotate. Due to the inclination of the valve axis, the inclined arrangement of turntable assembly 4 can ensure vertical press-fitting without pressing obliquely.

[0026] Preferably, the base 1 is fixed with an inclined table 1a, on which a bearing mounting plate 8 is fixedly installed, and the turntable assembly 4 is rotatably mounte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com