Method of improving coloring efficiency of surimi products in oil-frying process by using microwave heating

A surimi product, microwave power technology, applied in the direction of food ingredients as color, food ingredients as taste improver, food science, etc. The effect of shortening the surface dehydration time, eliminating the burden of sewage treatment, and improving the coloring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

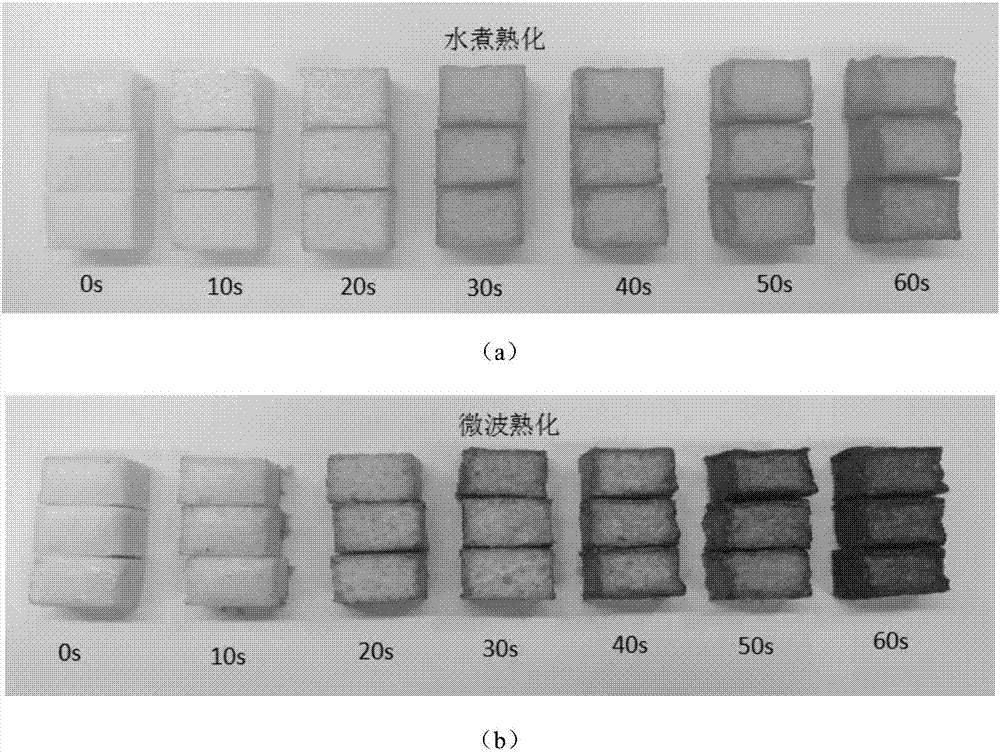

[0028] Embodiment 1 adopts the two-stage boiling and ripening mode to produce fish tofu

[0029] The formula of fish tofu used in this embodiment is as follows: 300g of frozen minced fish, 105g of starch, 128g of soybean protein emulsified paddle, 70g of ice water, 29g of fat meat, 35g of egg white, 14g of salt, 7g of white granulated sugar, 5g of monosodium glutamate, 3.5g of xylose, Glucose 3.5g.

[0030] The steps for making fish tofu used in this example are as follows: 1. Thawing: the frozen silver carp surimi (AA grade) sold under the trade name frozen surimi (AA grade) by Qianjiang Liuwu Aquatic Food Co., Ltd. was thawed overnight at a temperature of 4° C. When the surface temperature of the surimi is below 10°C, and the central temperature of the surimi is below -4°C, then cut into cubes (about 1.5×1.5×1.5cm in size) for later use; ② chopping and mixing: weigh 300g of thawed and diced surimi , in a high-speed chopping machine sold under the brand name "Shenfa" by Shan...

Embodiment 2

[0034] Embodiment 2 adopts microwave ripening mode to produce fish tofu

[0035] The formula of fish tofu used in this embodiment is as follows: 300g of frozen minced fish, 105g of starch, 128g of soybean protein emulsified paddle, 70g of ice water, 29g of fat meat, 35g of egg white, 14g of salt, 7g of white granulated sugar, 5g of monosodium glutamate, 3.5g of xylose, Glucose 3.5g.

[0036] The steps for making fish tofu used in this example are as follows: 1. Thawing: the frozen silver carp surimi (AA grade) sold under the trade name frozen surimi (AA grade) by Qianjiang Liuwu Aquatic Food Co., Ltd. was thawed overnight at a temperature of 4° C. When the surface temperature of the surimi is below 10°C, and the central temperature of the surimi is below -4°C, then cut into cubes (about 1.5×1.5×1.5cm in size) for later use; ② chopping and mixing: weigh 300g of thawed and diced surimi , in a high-speed chopping machine sold under the brand name "Shenfa" by Shanghai Shenfa Mach...

Embodiment 3

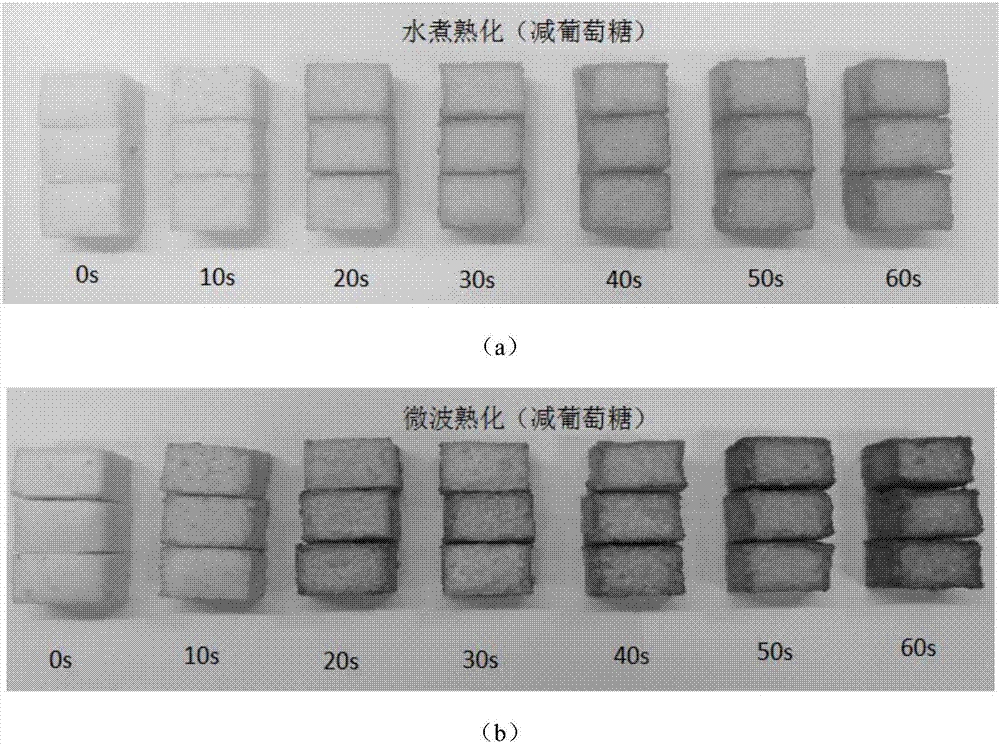

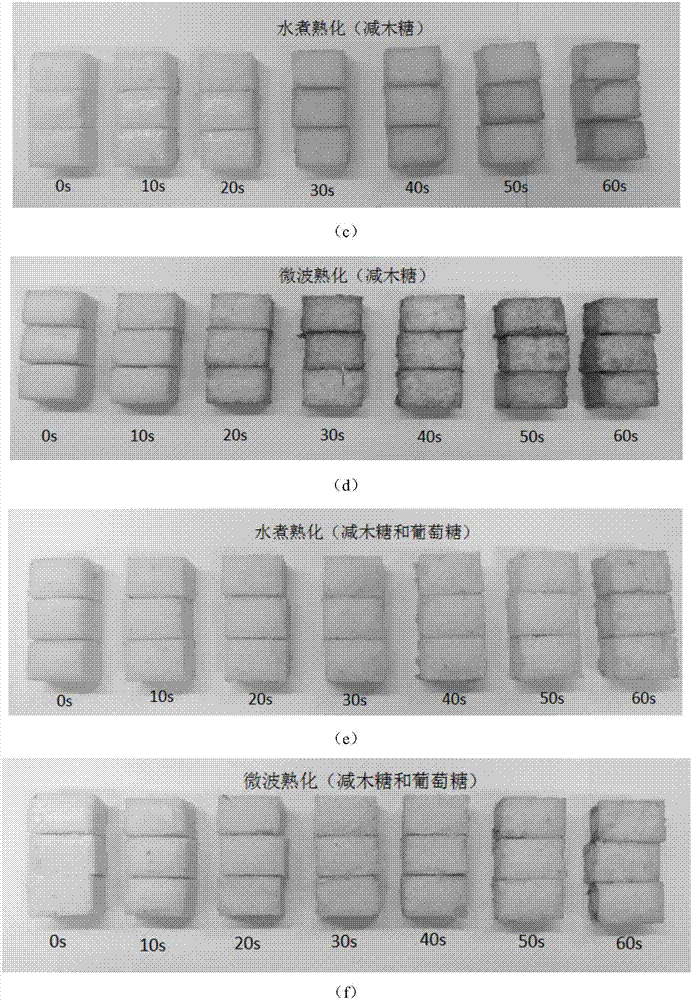

[0040] Embodiment 3 adopts the two-stage boiling and ripening mode (subtracting the coloring sugar component in the formula) to produce fish tofu

[0041] This example adopts a two-stage boiling method, and compares it with other examples by reducing the chromogenic components in the formula, specifically including the following three implementation methods: (1) subtracting the xylose component in the formula; (2) Subtract the glucose component in the formula; (3) Subtract the xylose and glucose components in the formula. The fish tofu recipes used are as follows: (1) 300g frozen surimi, 105g starch, 128g soybean protein emulsified paddle, 70g ice water, 29g fat meat, 35g egg white, 14g salt, 7g white sugar, 5g monosodium glutamate, and 3.5g glucose. (2) Frozen surimi 300g, starch 105g, soybean protein emulsified paddle 128g, ice water 70g, fat meat 29g, egg white 35g, salt 14g, white sugar 7g, monosodium glutamate 5g, xylose 3.5g. (3) Frozen surimi 300g, starch 105g, soybean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com