Fermented bean dreg paste

A technology of fermenting bean dregs and bean dregs, which is applied in food science and other fields, can solve problems such as waste of resources, and achieve the effects of removing dregs, diluting the fermented natto flavor, and increasing aroma and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

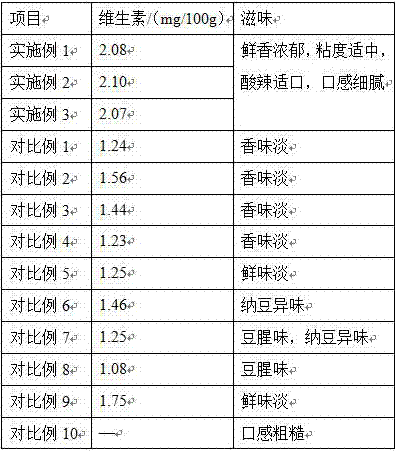

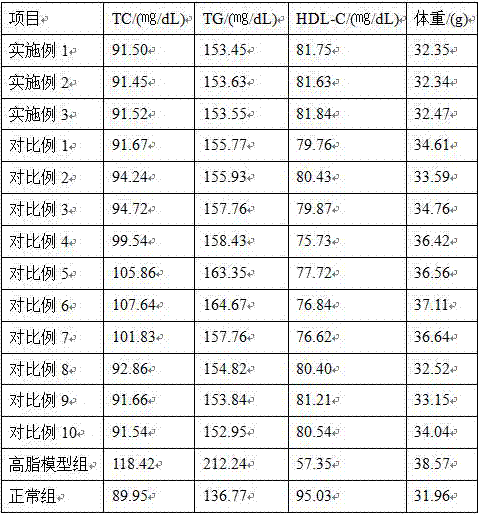

Examples

Embodiment 1

[0023] A fermented bean dregs sauce made from the following raw materials in parts by weight: 64 bean dregs, 22 brine, 17 peanuts, 17 millet, 11 carrots, 3 bacteria natto, 4 lactic acid bacteria, and 0.4 garlic extract;

[0024] The brine is to wash the spices and stir-fry until they are fragrant, add cold water, the amount of water added is 4100 times the weight of the spices, heat and boil, then naturally cool to 40~45°C, heat and boil again to the original volume of 1 / 2, filtered to obtain brine; the spices are composed of the following raw materials in parts by weight: salt 22, dried red pepper 14, shallot 17, ginger 11, pepper 6, Chinese prickly ash 6, cardamom 6, tangerine peel 5, grass fruit 5.

[0025] The lactic acid bacteria are composed of the following raw materials in parts by weight: Lactobacillus delbrueckii 13, Lactobacillus bulgaricus 11, and Lactobacillus casei 6.

[0026] For the garlic extract, heat edible oil to 90-100°C, add minced garlic, mix well, con...

Embodiment 2

[0040] A fermented bean dregs sauce is made from the following raw materials in parts by weight: 65 parts by weight of bean dregs, 23 parts of brine, 18 parts of peanuts, 18 parts of millet, 12 parts of carrots, 4 parts of natto bacteria, 5 parts of lactic acid bacteria and 0.5 parts of garlic extract;

[0041] The brine is washed and fried until fragrant, then added to cold water, the amount of water added is 4200 times the weight of the spices, heated and boiled, then naturally cooled to 40-45°C, heated and boiled again until the volume is 1 / 2, filtered to obtain brine; the spices are composed of the following raw materials in parts by weight: 23 salt, 15 dried red pepper, 18 chives, 12 ginger, 7 pepper, 7 pepper, 7 cardamom, 6 tangerine peel, grass fruit 6.

[0042] The lactic acid bacteria are composed of the following raw materials in parts by weight: Lactobacillus delbrueckii 14, Lactobacillus bulgaricus 12, Lactobacillus casei 7.

[0043]For the garlic extract, heat e...

Embodiment 3

[0047] A fermented bean dregs sauce, made of the following raw materials in parts by weight: 66 bean dregs, 24 brine, 19 peanuts, 19 millet, 13 carrots, 5 bacteria natto, 6 lactic acid bacteria, and 0.6 garlic extract;

[0048] The brine is washed and fried until fragrant, then added to cold water, the amount of water added is 4300 times the weight of the spices, heated and boiled, then naturally cooled to 40-45°C, heated and boiled again until the volume is 1 / 2, filtered to obtain brine; the spices are composed of the following raw materials in parts by weight: 24 salt, 16 dry red pepper, 19 chives, 13 ginger, 8 pepper, 8 pepper, 8 cardamom, 7 tangerine peel, grass fruit 7.

[0049] The lactic acid bacteria are composed of the following raw materials in parts by weight: Lactobacillus delbrueckii 15, Lactobacillus bulgaricus 13, Lactobacillus casei 8.

[0050] For the garlic extract, heat edible oil to 90-100°C, add minced garlic, mix well, continue heating to 110-115°C, nat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com