Fan wheel structure of cooling fan

A heat dissipation fan and fan wheel technology, applied in non-variable pumps, pump components, components of pumping devices for elastic fluids, etc., can solve problems such as easy breakage of joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described based on the preferred embodiments of the accompanying drawings.

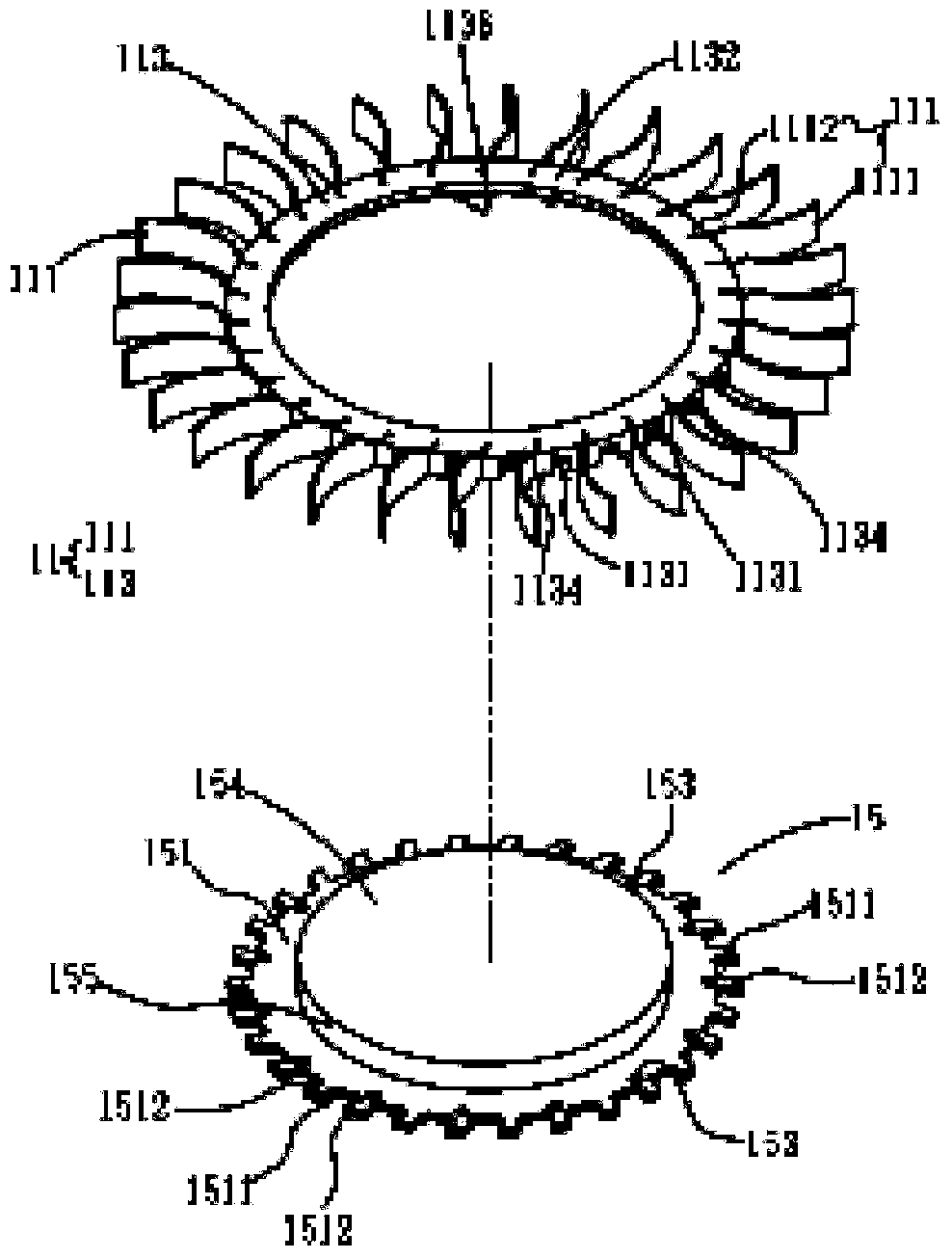

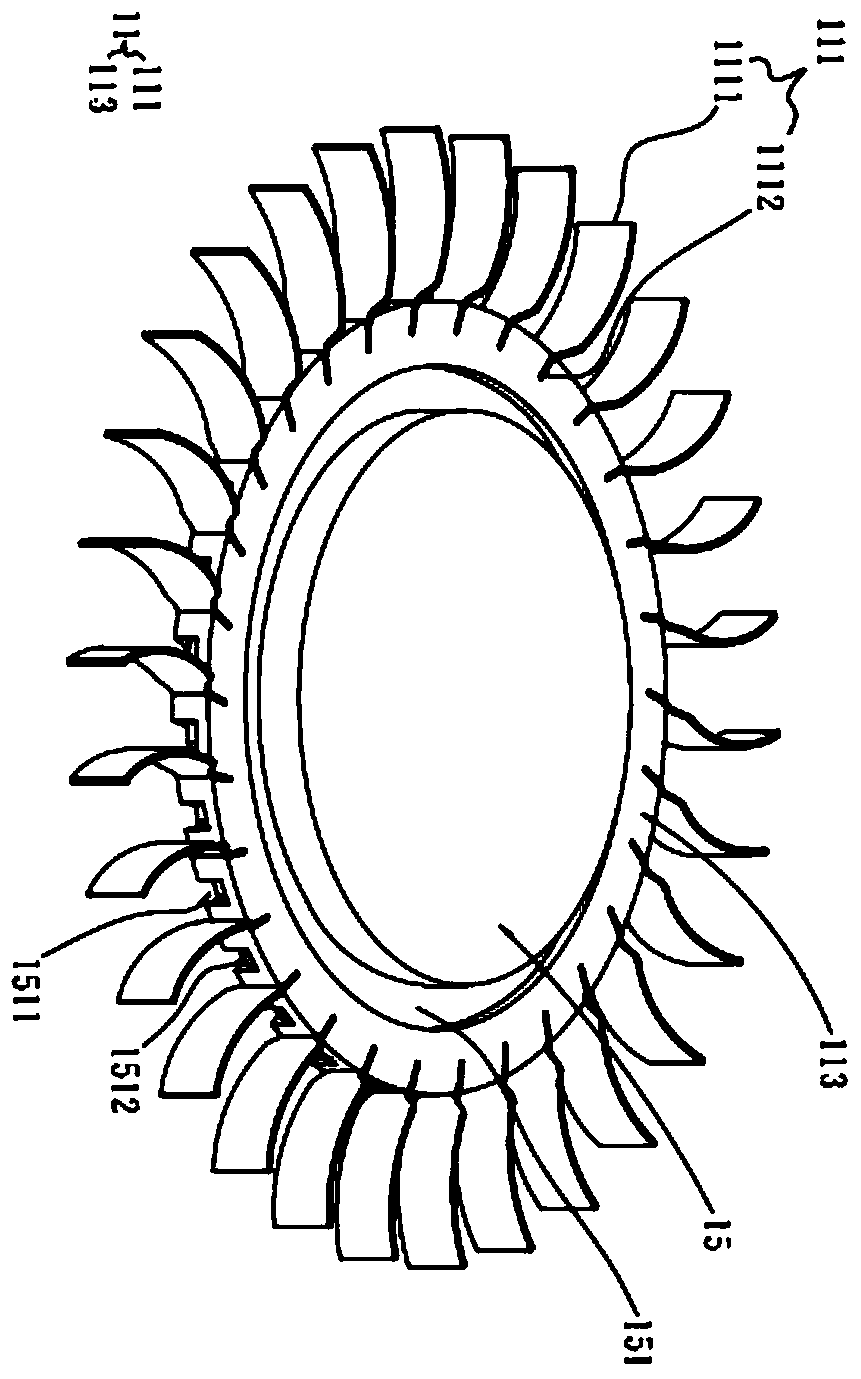

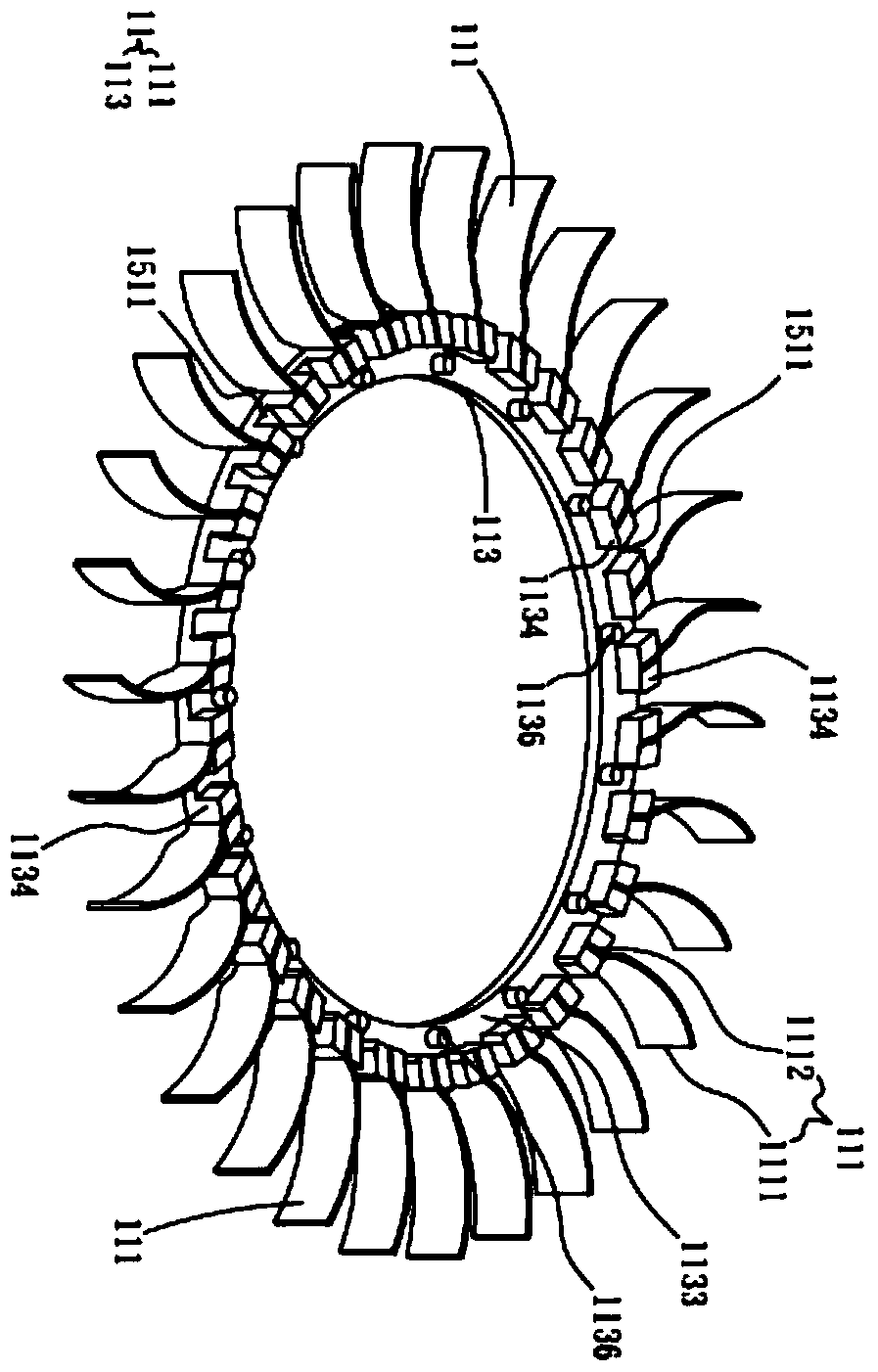

[0038] refer to Figure 1A and Figure 1B It is a three-dimensional schematic diagram of the decomposition and assembly of the first embodiment of the present invention, supplemented by reference image 3 . The present invention provides a fan wheel structure of a cooling fan. The cooling fan in this embodiment is, for example, a centrifugal fan (not shown in the figure). The aforementioned fan wheel structure 1 includes a fan blade set 11 and a hub 15. The fan blade set 11 has a plurality of blades 111 and a ring cover 113. The material of these blades 111 can be a metal material with ductility and good strength. , such as aluminum, aluminum alloy, steel, iron or titanium alloy, but the present invention is not limited thereto. And these blades 111 have a front end 1111, a rear end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com