Operation frame body capable of canceling backfilling of basement outer wall and construction method

A basement external wall and construction method technology, which is applied in excavation, infrastructure engineering, wine cellars, etc., can solve the problems of reducing the use area of the basement, waste of operating frames, and heavy workload, so as to simplify the process of building the basement and save energy. Labor costs and the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

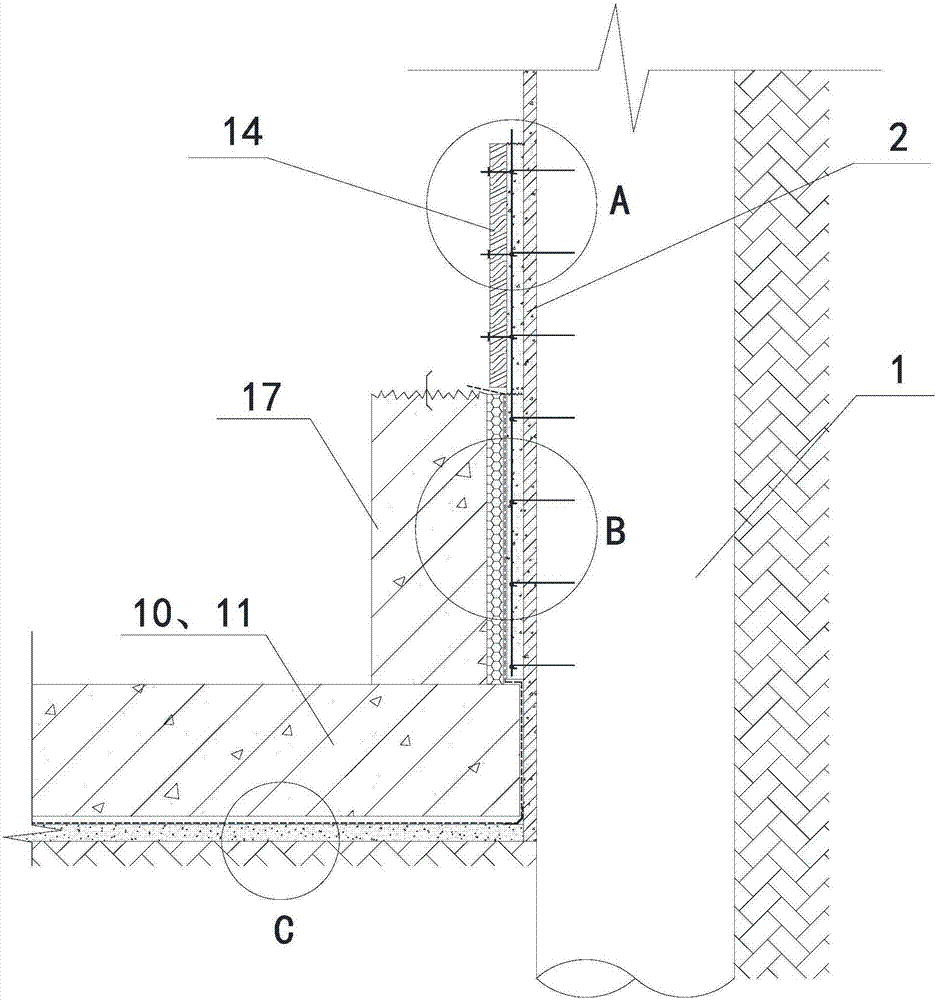

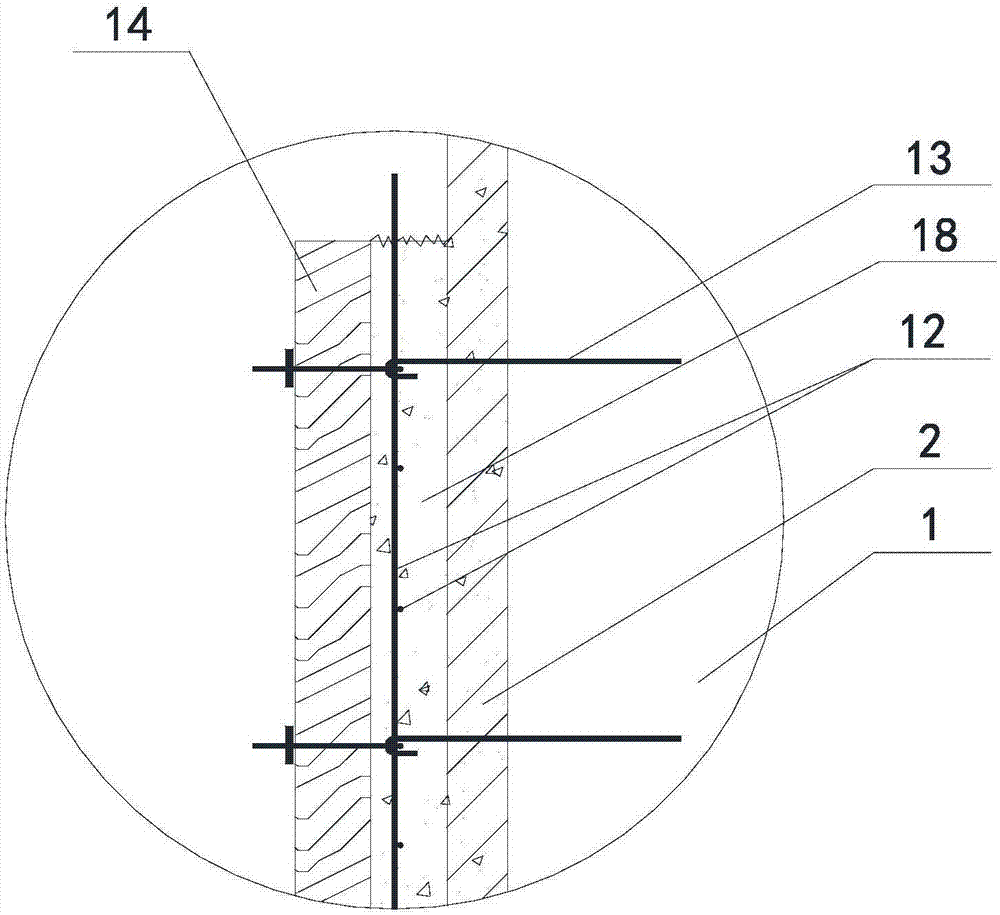

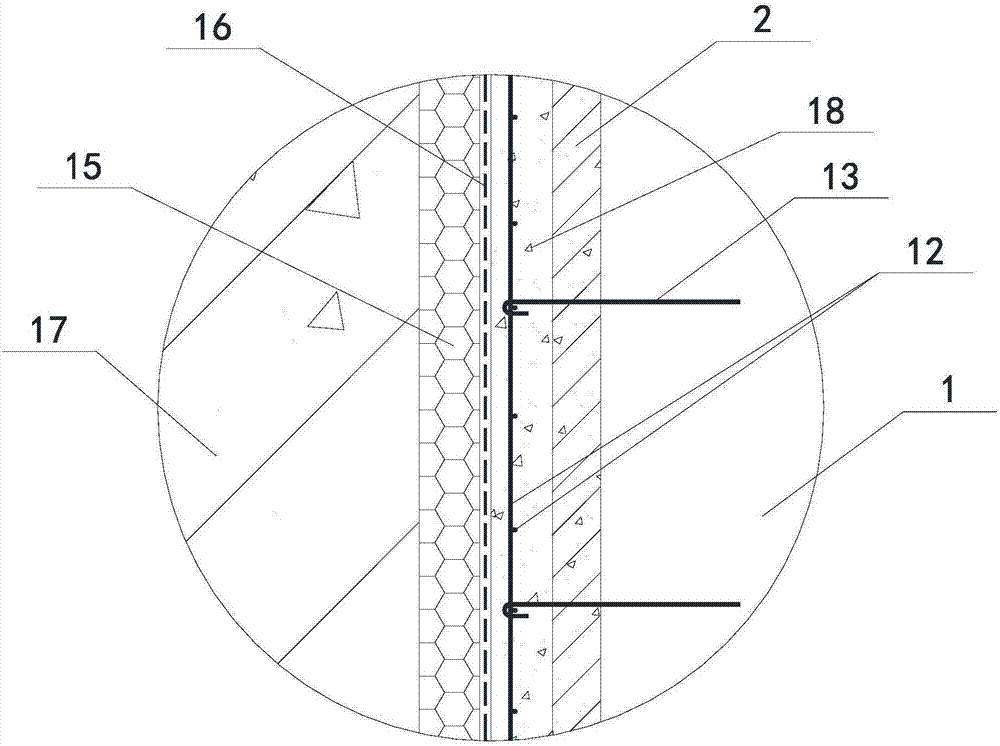

[0061] Such as Figure 5-Figure 7 Shown:

[0062] An operating frame body for canceling the backfilling of the outer wall of a basement includes several support piles 1, and the support piles 1 are rotary drilling bored piles. The shape of several supporting piles 1 arrangement is adapted to the shape of the foundation pit, and the quantity of supporting piles 1 is determined according to the size of the basement construction. In this embodiment, take a rectangular basement as an example, such as Figure 5 As shown, there are 34 support piles 1, the distance between adjacent support piles is 2.3m, and the adjacent support piles are on the side of the empty surface of support piles 1 after foundation pit excavation ( Figure 7 The side B in is the free surface, Figure 7 A side in the middle is the soil surface) sprayed with a concrete base 2, and the thickness a of the concrete base 2 is 80mm; in the concrete base 2, a steel mesh sheet-3 is provided, and the outside of the...

Embodiment 2

[0066] Such as Figure 1-Figure 7 Shown:

[0067] The construction method for canceling the backfilling of the basement outer wall by adopting the operating frame body for canceling the backfilling of the basement outer wall in the above-mentioned embodiment 1 includes the following steps:

[0068] (1) construct the operating frame body that cancels the backfilling of the basement wall in Example 1:

[0069] a, construction foundation pit support pile 1, this support pile 1 adopts the rotary drilling bored pile;

[0070] b. Excavation of earth and stone, sprayed concrete base 2 between support piles 1 after excavation;

[0071] Before the sprayed concrete base 2, the reinforcement mesh 1 3 in the concrete base 2, the external pressure reinforcement reinforcement 4 and the reinforcement 6 are arranged according to the following design scheme:

[0072] ①Reinforcement mesh one 3: Φ8@200 double-layer two-way reinforcement mesh is arranged on the inner side of support pile 1;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com