Method for producing breast pads and breast pads obtained therefrom

A production method and technology of breast pads, applied in the field of production methods and the obtained breast pads, can solve the problem of high proportion of waste materials, and achieve the effects of high production efficiency, simple process, and reasonable distribution of water-absorbing surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] See Figure 10-12 , the production method of the breast pad of the present embodiment comprises the steps:

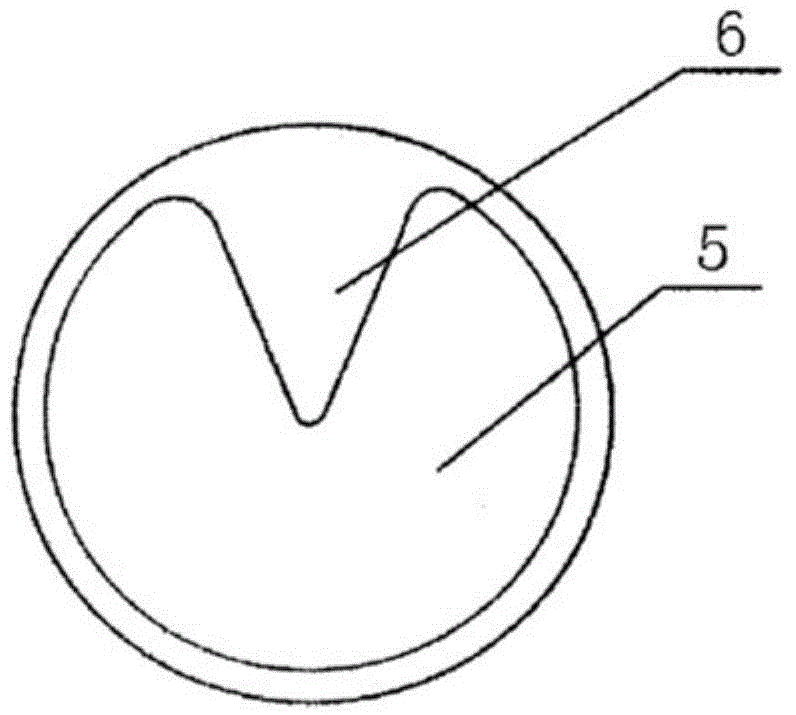

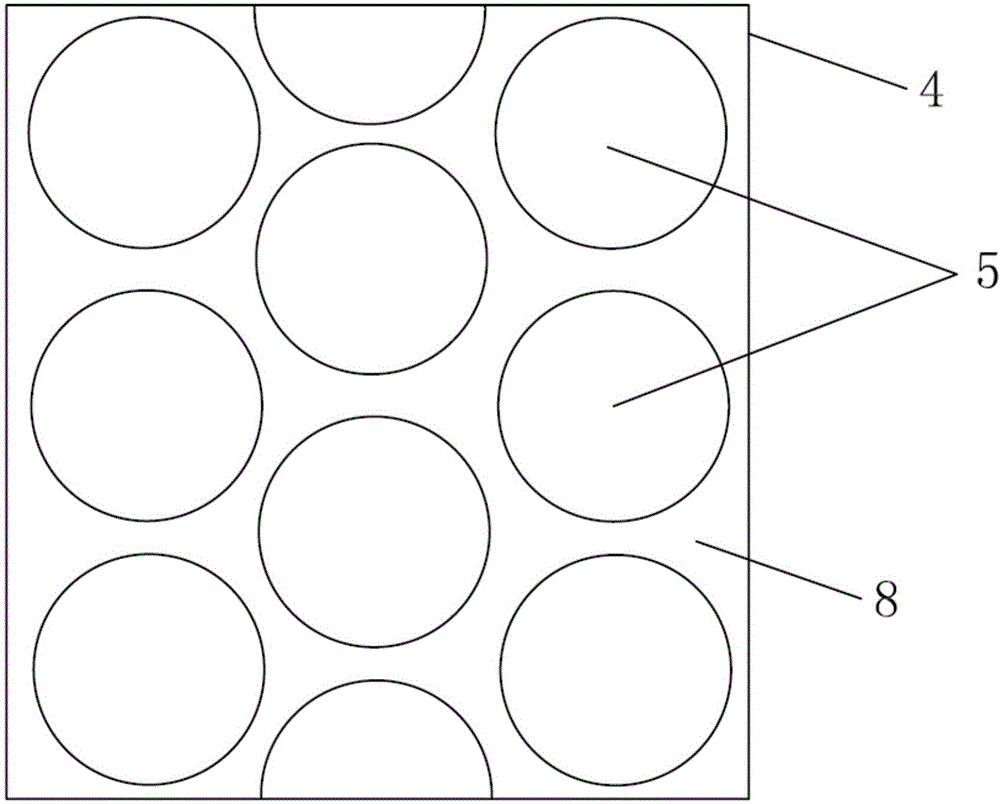

[0033] A. Lay a water-absorbing layer on the waterproof layer or the water-conducting layer; wherein, the water-absorbing layer includes multiple vertical rows alternated along the length direction of the substrate 4 (the substrate 4 includes a waterproof layer and a water-conducting layer stacked up and down) parallel A plurality of semicircular or substantially semicircular water-absorbing units 3 are arranged; as shown in the figure, the water-absorbing unit 3 includes: an arc portion 3-1 and a radial portion 3-2. The water-absorbing units 3 in the same row are symmetrically distributed sequentially along the arrangement direction, the water-absorbing units 3 in the adjacent columns opposite to each other are arranged alternately, and the arcs of the water-absorbing units 3 in any row 3-1 can be projected on the arc portion 3-1 of the adjacent water-absorbing...

Embodiment 2

[0040] like Figure 5 The half-body 2 of the breast pad in the base material 4 adopts another distribution method. After each half-body 2 of the breast pad is cut off, a pair of half-body 2 of the breast pad is welded along the radial line to form a breast pad. Mat finished.

Embodiment 3

[0042] On the basis of above-mentioned embodiment 1, the difference of this embodiment is:

[0043] Stack the two base materials up and down, and the upper and lower adjacent pairs of breast pad halves formed after stacking are stacked symmetrically up and down, and then ultrasonically welded along the edges of the radial parts of each pair of superimposed breast pad halves or hot melt connection.

[0044] In this step, there is no need to turn over the base material, and only need to ensure that the material is set, and the step of ultrasonic welding or thermal fusion connection can be performed, which can further improve production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com