Discharge printing process of reactive dyes based on jet ink printing technology

A reactive dye, discharge printing technology, applied in the direction of dyeing, textile and paper making, etc., can solve the problems of unclear outline of the pattern, inability to perform double-sided discharge, and inability to use inkjet printing, etc., to achieve bright and realistic colors, Small footprint and fast printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

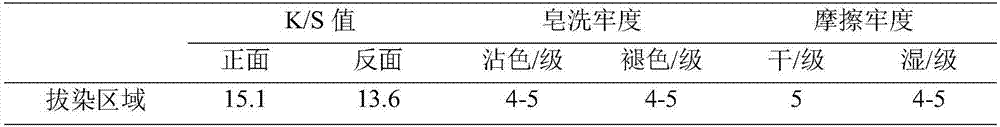

Embodiment 1

[0026] A reactive dye discharge printing process based on inkjet printing technology includes the following steps: sizing→drying→dying ground color→computer design pattern→preparing discharge ink and spray printing→steaming fixation→washing and drying.

[0027] (1) Sizing treatment: The prescription of the sizing agent is: 30% sodium alginate paste, 3% dispersant, 2% anti-migration agent.

[0028] (2) Drying: Dry the fabric after sizing treatment at 80 to 60% dry.

[0029] (3) Dyeing the ground color: using pad dyeing process for dyeing. The recipe of the reactive dye ground color pad dyeing solution is: reactive dye X: 3%, urea 5%, anti-dyeing salt S 2%, baking soda 2%, sodium alginate paste 50%, total liquid volume 100%.

[0030] (4) Computerized printing and color separation (CAD) editing process: Through the description and editing process, the desired pattern is obtained, and the ink jet nozzle is controlled by the computer.

[0031] (5) Preparation of discharge ink and jet printi...

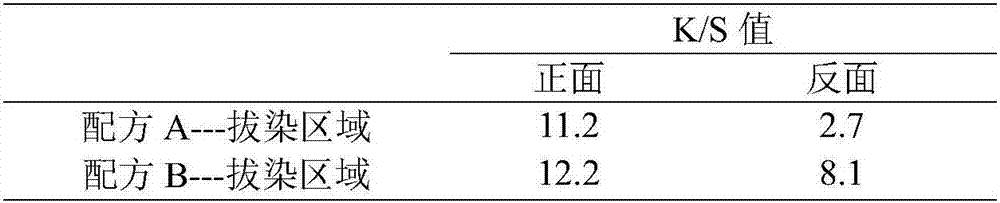

Embodiment 2

[0045] A reactive dye discharge printing process based on inkjet printing technology includes the following steps: sizing→drying→dying ground color→computer design pattern→preparing discharge ink and spray printing→steaming fixation→washing and drying.

[0046] (1) Sizing treatment: The prescription of the sizing agent is: 35% sodium alginate paste, 4% dispersant, 3% anti-migration agent.

[0047] (2) Drying: Dry the fabric after sizing treatment at 80 to 60% dry.

[0048] (3) Dyeing the ground color: using pad dyeing process for dyeing. The recipe of the reactive dye ground color pad dyeing solution is: reactive dye X: 3%, urea 5%, anti-dyeing salt S 2%, baking soda 2%, sodium alginate paste 60%, total liquid volume 100%.

[0049] (4) Computerized printing and color separation (CAD) editing process: Through the description and editing process, the desired pattern is obtained, and the ink jet nozzle is controlled by the computer.

[0050] (5) Preparation of discharge ink and jet printi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com