Long glass fiber enhanced polypropylene composite material with low shrinkage and low warpage and preparation method and application thereof

A composite material, polypropylene technology, used in the manufacture of automobile tailgate panels, long glass fiber reinforced polypropylene composite materials and their preparation fields, can solve problems such as no better solutions, and achieve good appearance, manufacturing The effect of reducing shrinkage and warpage of parts and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4 and comparative example 1~4

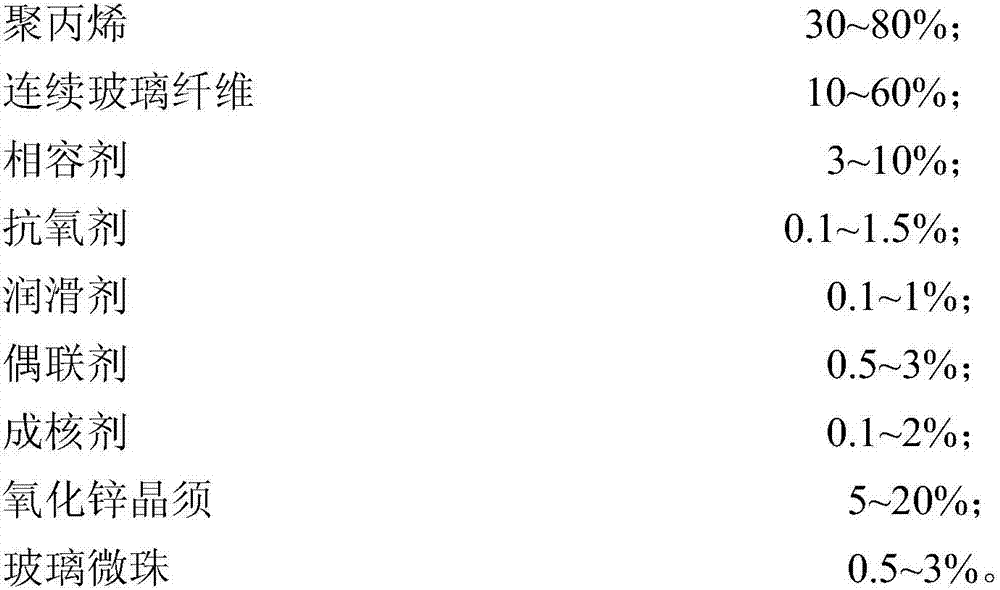

[0042] Low shrinkage, low warpage long glass fiber reinforced polypropylene composite materials, the raw material ratios of Examples 1 to 4 and Comparative Examples 1 to 4 are listed in Table 1 and Table 2 below, unless otherwise stated, percentages refer to Percentage by weight, the zinc oxide whiskers are four needle-shaped zinc oxide whiskers, the length of the needle-shaped body is 10-50 μm, the root of the needle-shaped body is 0.5-5 μm, the aspect ratio is 20-50, and the apparent density is 0.2±0.1g / cm 3 , the true density is 5.4±0.2g / cm 3, heat resistance 800 ~ 1800 ℃; glass beads are hollow glass beads, the density is 0.2g / cm 3 ~0.7g / cm 3 , the particle size distribution is between 5 and 35 microns.

[0043] The preparation method of low shrinkage and low warpage long glass fiber reinforced polypropylene composite material comprises the following steps:

[0044] (1) drying the zinc oxide whiskers at 80°C for 4 hours to obtain dried zinc oxide whiskers;

[0045] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com