Powder coating composition, powder coating, and coated article

A powder coating and composition technology, which is applied in powder coatings, devices for coating liquid on surfaces, coatings, etc., can solve problems such as poor weather resistance of coating films, and achieve the effect of excellent surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

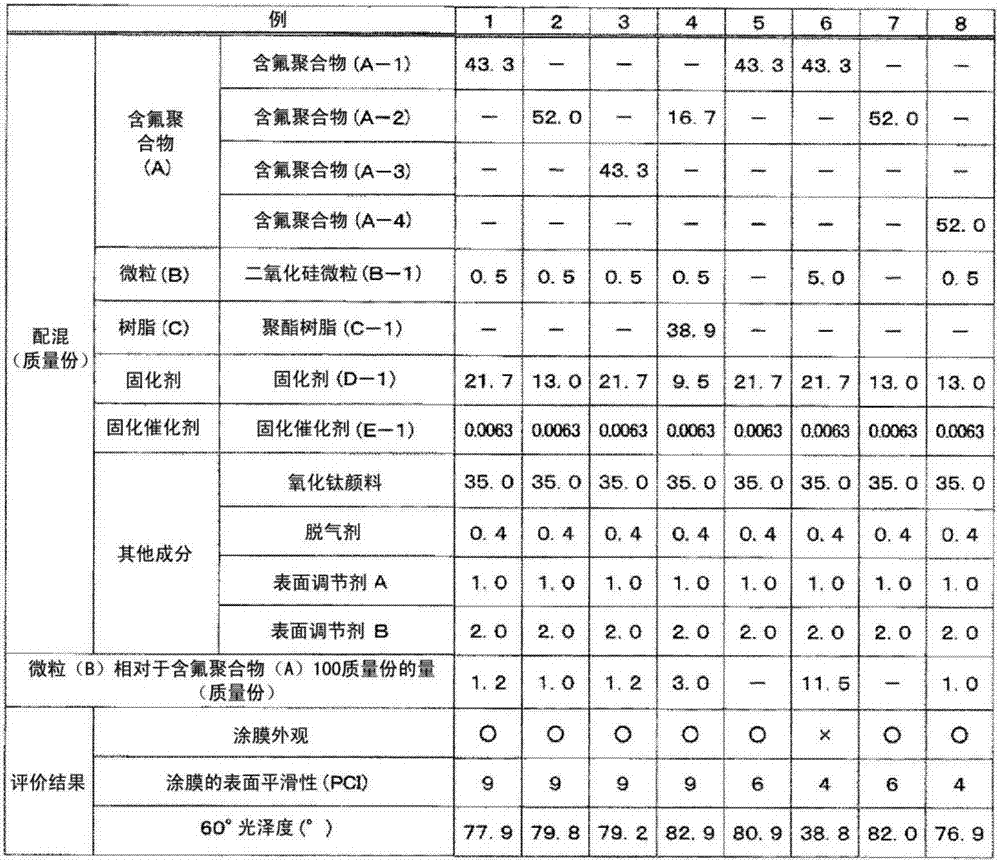

[0260]Hereinafter, although an Example is given and this invention is demonstrated in detail, this invention is not limited to these Examples.

[0261] In addition, in the following examples, examples 1-4 are examples, and examples 5-8 are comparative examples.

[0262] [various measurement methods]

[0263] (Copolymerization composition of fluoropolymer (A))

[0264] pass 1 H-NMR and 13 Calculated by C-NMR.

[0265] (melt viscosity)

[0266] The melt viscosity at 190° C. is a value measured on the following conditions using a rotational rheometer (manufactured by Anton Paar JAPAN, Rheometer MCR302).

[0267] Temperature: from 130°C to 200°C, measure the melt viscosity at 190°C

[0268] Heating rate: 10°C / min

[0269] Frequency: 1Hz

[0270] (glass transition temperature (Tg))

[0271] The glass transition temperature (Tg) is a value measured by a differential calorimeter (DSC).

[0272] (number average molecular weight (Mn))

[0273] The number average molecular we...

manufacture example 1

[0274] [Production Example 1: Production of Fluoropolymer (A-1)]

[0275] 210.7 g of cyclohexyl vinyl ether (CHVE), 282.1 g of hydroxybutyl vinyl ether (HBVE), 122.0 g of ethyl vinyl ether (EVE), xylene 647.2 g, 168.8 g of ethanol, 11.0 g of potassium carbonate, 7.0 g of a 50% by mass xylene solution of tert-butyl peroxypivalate (PBPV), and 680.0 g of chlorotrifluoroethylene (CTFE). Then, the temperature was raised slowly, and after reaching 55° C., it was maintained for 20 hours. Then the temperature was raised to 65°C and kept for 5 hours. Then, it was cooled and filtered to remove the residue to obtain a xylene solution of the fluoropolymer (A-1).

[0276] Thin-film evaporation was performed on the obtained xylene solution, and it dried until the solid content concentration became 99.5 mass %.

[0277] The copolymer composition of the dried fluoropolymer (A-1) thus obtained was CTFE unit / HBVE unit / CHVE unit / EVE unit=50 / 20 / 15 / 15 (mol %). In addition, the glass transition...

manufacture example 2

[0278] [Production Example 2: Production of Fluoropolymer (A-2)]

[0279] 104.0 g of tert-butyl vinyl ether (t-BuVE), 132.0 g of hydroxybutyl vinyl ether (HBVE), and 385.0 g of vinyl pivalate (VPV) were introduced into a stainless steel autoclave with a stirrer with an inner volume of 2500 mL. g, 555.0 g of xylene, 157.0 g of ethanol, 11.0 g of potassium carbonate, 7.0 g of a 50% by mass xylene solution of tert-butyl peroxypivalate (PBPV), and 630.0 g of chlorotrifluoroethylene (CTFE). Then, the temperature was raised slowly, and after reaching 55° C., it was maintained for 20 hours. Then the temperature was raised to 65°C and kept for 5 hours. Then, it was cooled and filtered to remove the residue to obtain a xylene solution of the fluoropolymer (A-2).

[0280] Thin-film evaporation was performed on the obtained xylene solution, and it dried until the solid content concentration became 99.5 mass %.

[0281] The copolymer composition of the dried fluoropolymer (A-2) thus ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com