Low density edible animal chews and methods of making same

A chewable material and density technology, which is applied in the field of edible chewable material and preparation of such chewable material, can solve the problems of difficult monitoring of expansion of pregelatinized starch, difficult control of product shape, unsatisfactory and other problems, so as to achieve increased feeding opportunities, Reduce raw material costs and improve dental outcomes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Based on the percentages shown in Table 1, based on 500 kg of dry blend, the ingredients were weighed and added to the batch mixer to blend for five minutes. Although pregelatinized corn flour is used, pregelatinized cereal flour can be used as an alternative or in addition.

[0086] The dry blend was metered into an Evolum EV53 (Clextral) twin-screw extruder together with the glycerol / phosphoric acid mixture and water in the proportions shown in Table 1, and was heated at 115 kg / h, a pressure of 64 bar and a temperature of 117°C. Form a plastic dough. Phosphoric acid is not required, but may be added to provide an additional preservative effect.

[0087] Table 1

[0088]

[0089] The extruder was equipped with 10 barrel segments with an L / D ratio of 40. To achieve moderate shear, one reversing screw element was inserted at the end of the fourth barrel, and two such elements were inserted at the end of the fifth barrel. The screw rotated at 140 rpm and the dry ...

Embodiment 2

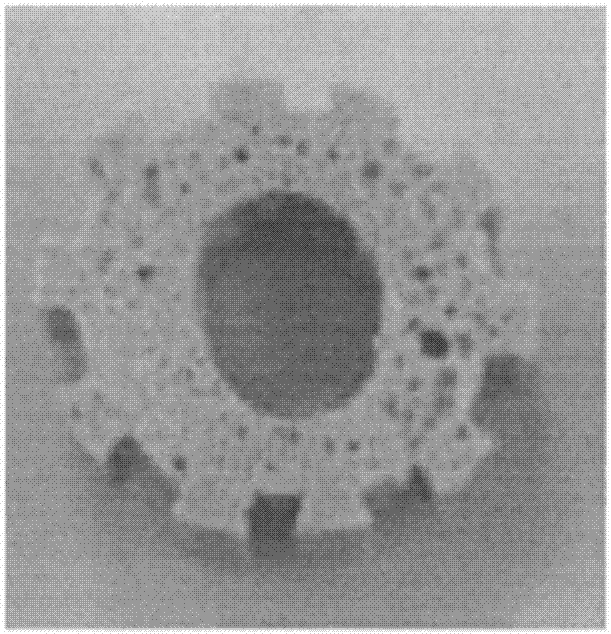

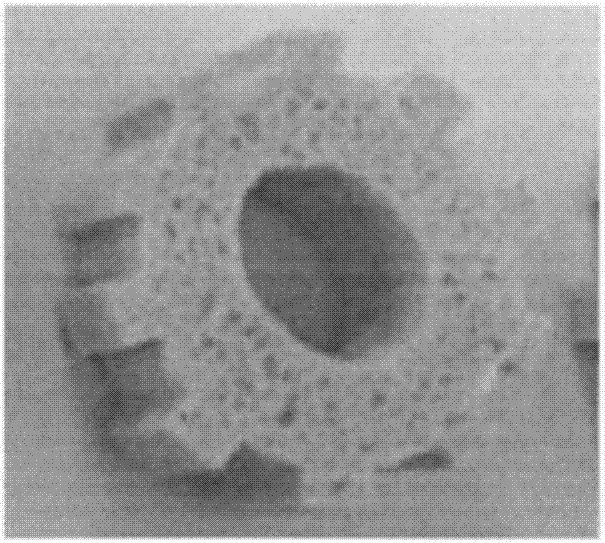

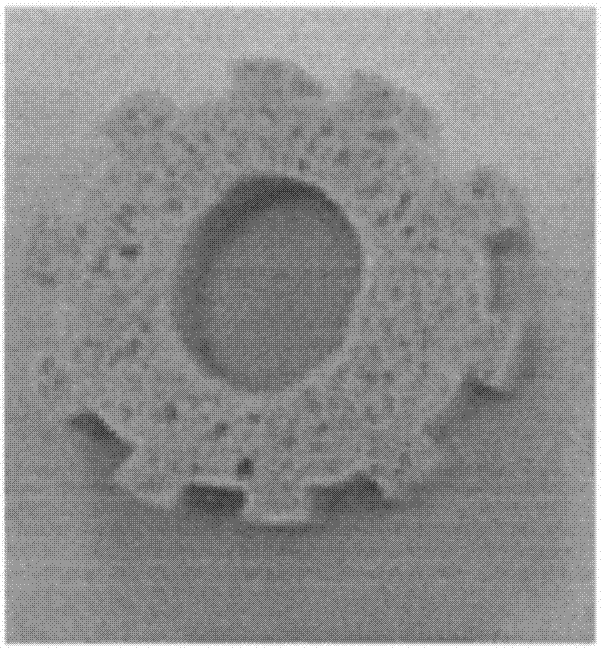

[0092] Example 1 was repeated with the following exceptions. 0.5% sodium bicarbonate was added to the dry blend shown in Table 1 and the pregelatinized corn flour was thus reduced to 83.08%. The maximum pressure and SME are 67 bar and 447KJ / Kg, respectively. The plastic dough is then passed through Image 6 The die system with opening shown was extruded and cut into 120 mm long pieces with a density of 0.74 Kg / L and an expanded porous internal structure ( figure 2 ). Dies with dovetail designs were found ( Image 6 ) avoids a blistered rough exterior surface and produces an acceptably smooth exterior surface. In addition, a single tubular insert is inserted within the mold opening to form a hollow in the product block ( figure 2 ).

Embodiment 3

[0094] Example 2 was repeated with the following exceptions. 1% sodium bicarbonate was added to the dry blend shown in Table 1, and the pregelatinized corn flour was thus reduced to 82.58%. The maximum pressure and SME are 67 bar and 452KJ / Kg, respectively. The plastic dough is then passed through Image 6 The die system with opening shown was extruded and cut into 120 mm long pieces with a density of 0.68 Kg / L and an expanded porous internal structure ( image 3 ). Dies with dovetail designs were found ( Image 6 ) avoids a blistered rough exterior surface and produces an acceptably smooth exterior surface. In addition, a single tubular insert is inserted within the mold opening to form a hollow in the product block ( image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com