A compressed air shock wave soot blower

A shock wave soot blower and compressed air technology, which is applied in the field of boiler tools, can solve the problems of poor shock wave generation quality, insignificant soot blowing effect, and high maintenance costs, and achieve power saving, wide application range, and low maintenance cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

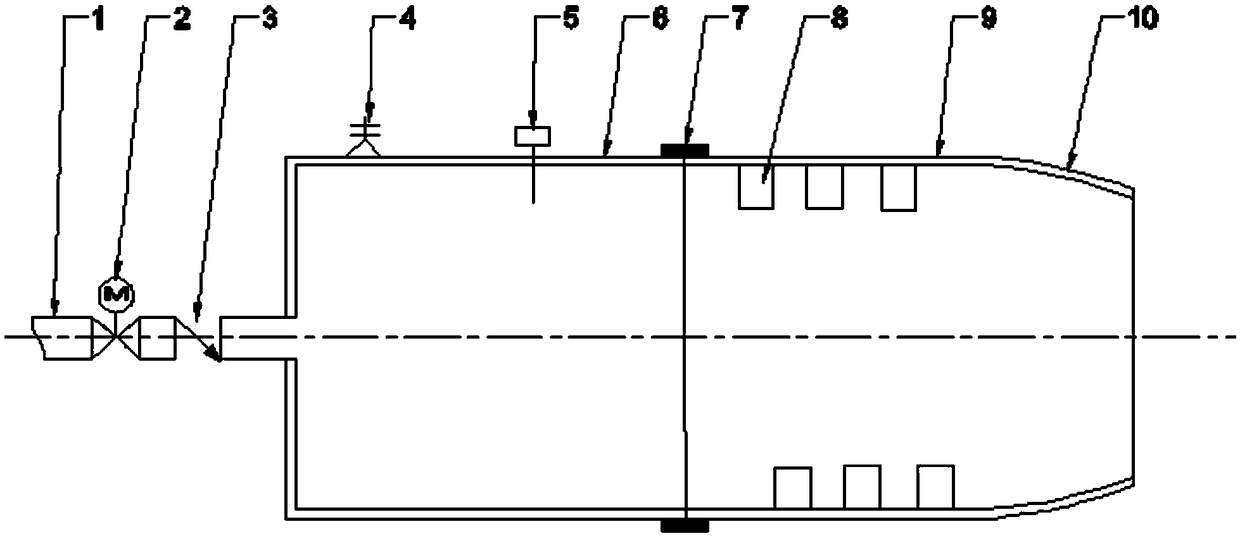

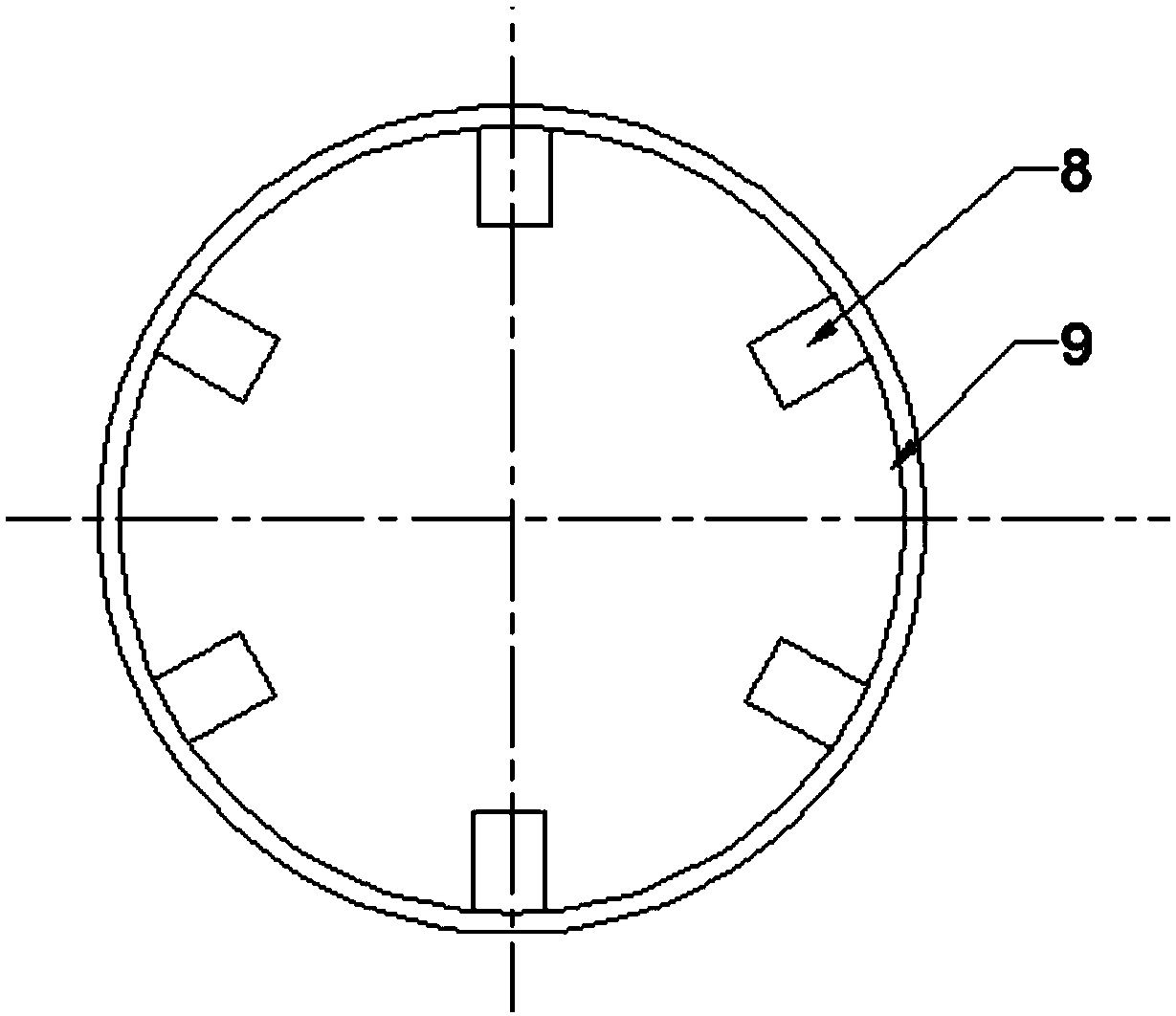

[0032] Such as figure 1 , 2 Shown, a kind of compressed air shock wave sootblower comprises high-pressure section, spoiler section and outlet section 10, and high-pressure section is connected with spoiler section, and spoiler section is connected with outlet section 10; Described high-pressure section, spoiler section The cross-section of the outlet section 10 is circular, the diameter of the turbulence chamber 9 is equal to that of the high-pressure chamber 6, the inlet end of the outlet section 10 is equal to the diameter of the turbulence chamber 9, and the outlet Section 10 is a tapered circular nozzle;

[0033] The high-pressure section includes a connecting pipeline 1, an electric stop valve 2, a one-way valve 3, an explosion relief valve 4, a pressure sensor 5 and a high-pressure chamber 6; The gas outlet end of the connecting pipe 1 communicates with the high pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com