Operating platform capable of realizing quick cleaning of petroleum pipeline machining waste chips

A technology for oil pipelines and consoles, which is applied to workbenches, metal processing equipment, metal processing machinery parts, etc. It can solve the problems of operator scratches, single function, and inability to meet the requirements of oil pipeline elbow clamping, etc., and achieves convenience The effect of iron filings cleaning and avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

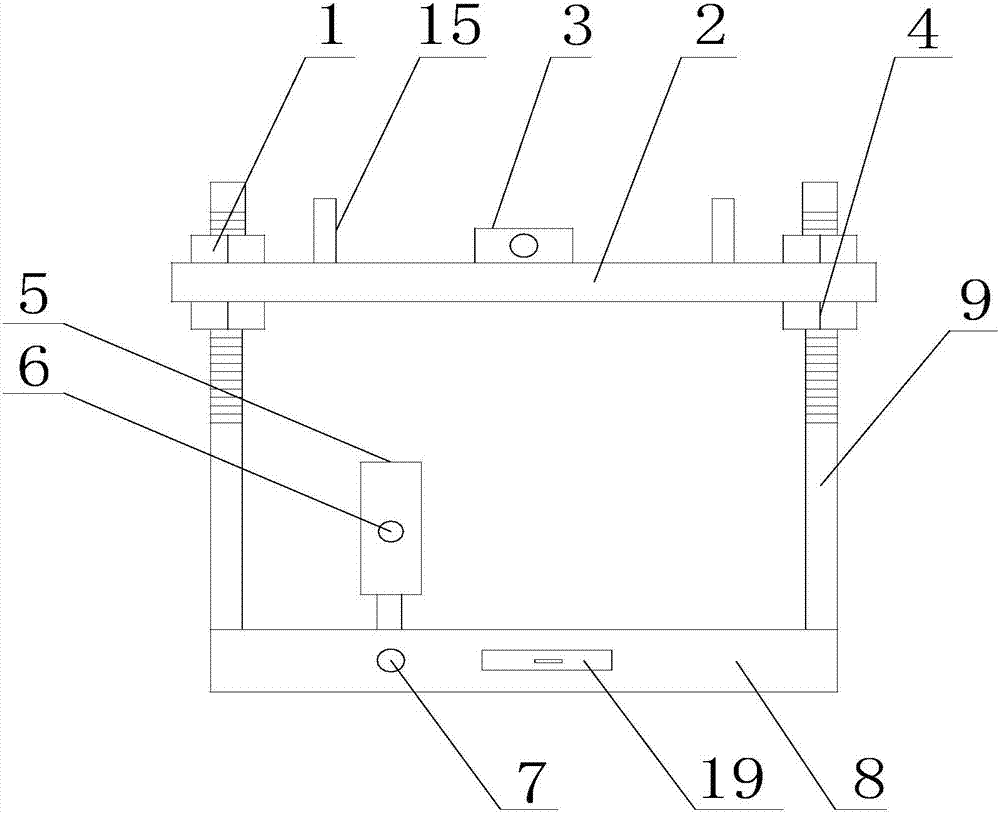

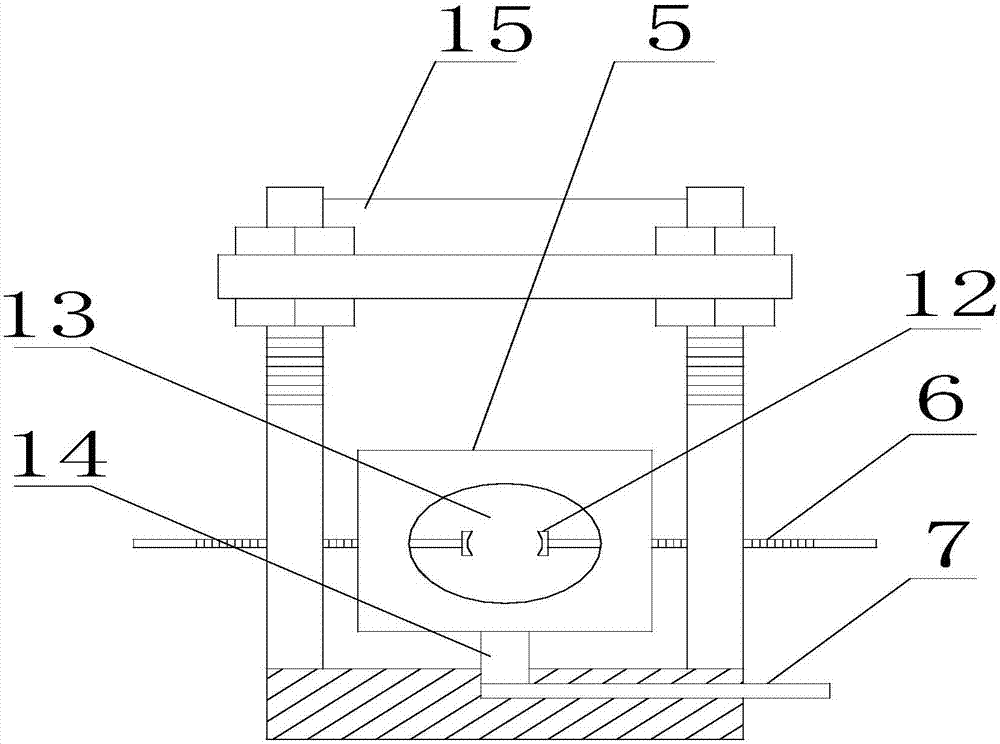

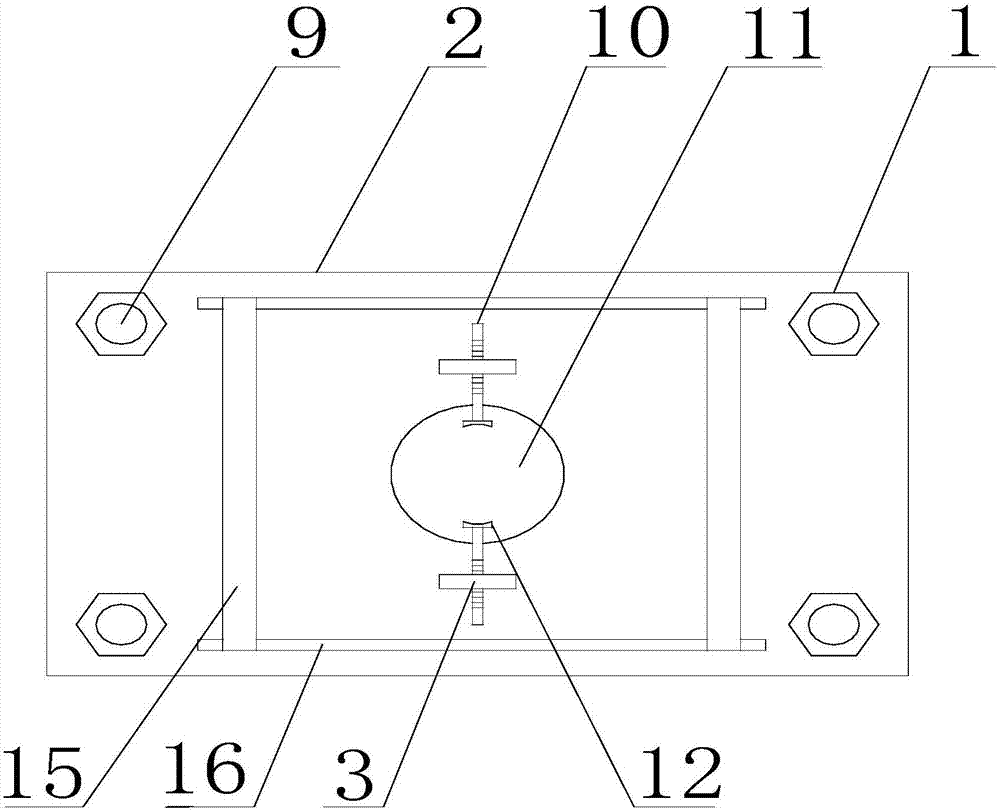

[0027] Such as Figure 1 to Figure 4 As shown, the operating table for quickly cleaning oil pipeline processing waste of the present invention includes a base 8 and a processing table 2, both of which are rectangular in structure, and the top of the base 8 is provided with four supporting columns 9, and the four supporting Columns 9 are respectively located at the four corners of the base 8, and four support columns 9 are inserted on the processing table 2, and the support columns 9 are also provided with a first nut 1 and a second nut 4, the first nut 1 and the second nut The nuts 4 are all connected to the support column 9 by threads, and the processing table 2 is located between the first nut 1 and the second nut 4, and the heights of the first nut 1 and the second nut 4 can be adjusted according to actual use needs. The distance between the processing table 2 and the base 8 meets the needs of elbows of different lengths; the top of the processing table 2 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com