Industrial exhaust gas and suspended particulate matter purifying processing system

A technology for purification and treatment of industrial waste gas, which is applied in the fields of climate change adaptation, climate sustainability, and dispersed particle separation. Low cost, good purification effect and less equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

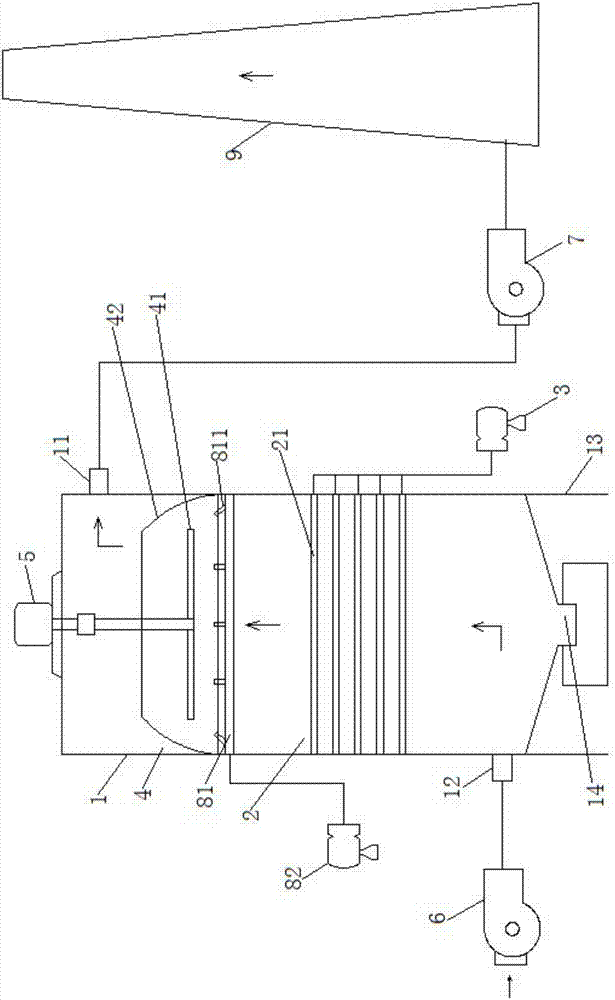

[0048] Example: such as figure 1 , 3 As shown, the industrial waste gas and suspended particulate matter purification treatment system of this embodiment includes a purification cylinder 1, an atomization spray system, a dynamic physical aerosol separation system, a suction device 6 and an exhaust device 7;

[0049] The above-mentioned purification cylinder 1 is a cylindrical structure with a hollow inside. The above-mentioned cylindrical structure has a top wall and a bottom wall, and an air outlet 11 is provided on the upper side wall, and an air inlet 12 is provided on the lower side wall;

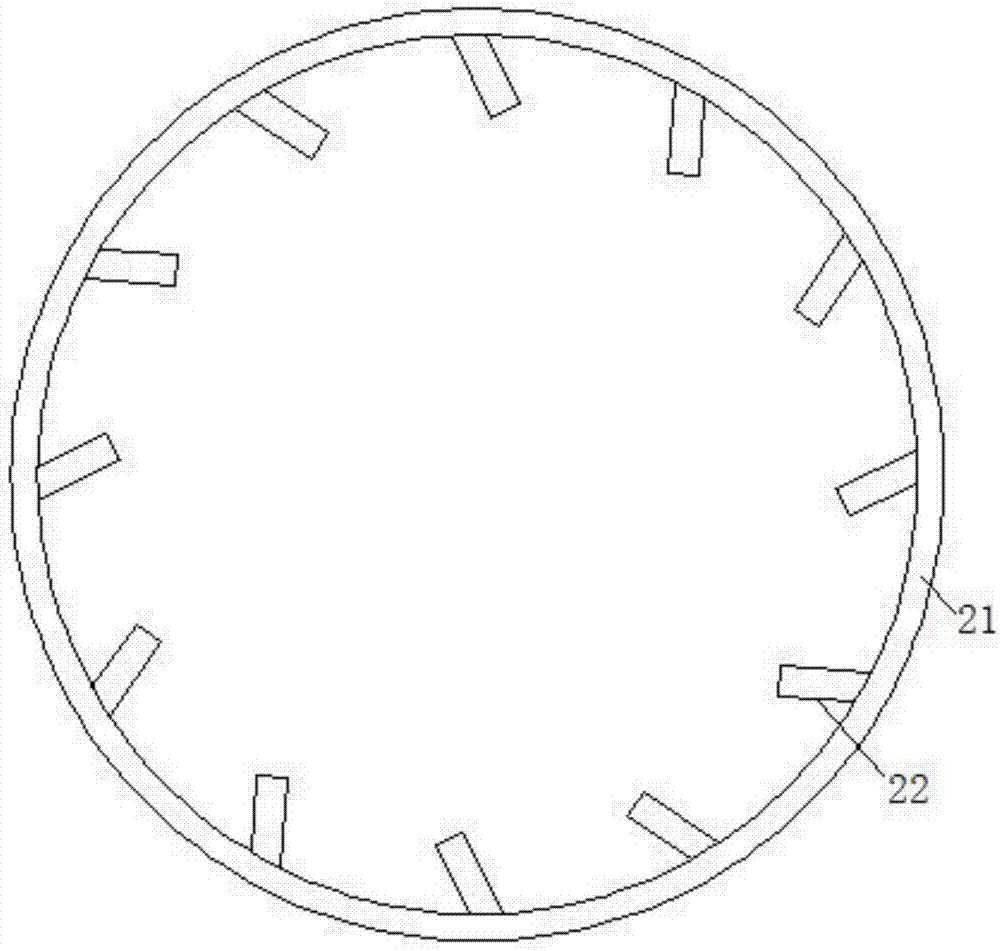

[0050] The atomization shower system includes an atomization shower mechanism 2 and a spray pump 3, the atomization shower mechanism 2 is arranged on the inner wall of the purification cylinder 1 and is close to the air inlet, and the spray pump 3 is connected to the atomization nozzle shower mechanism 2;

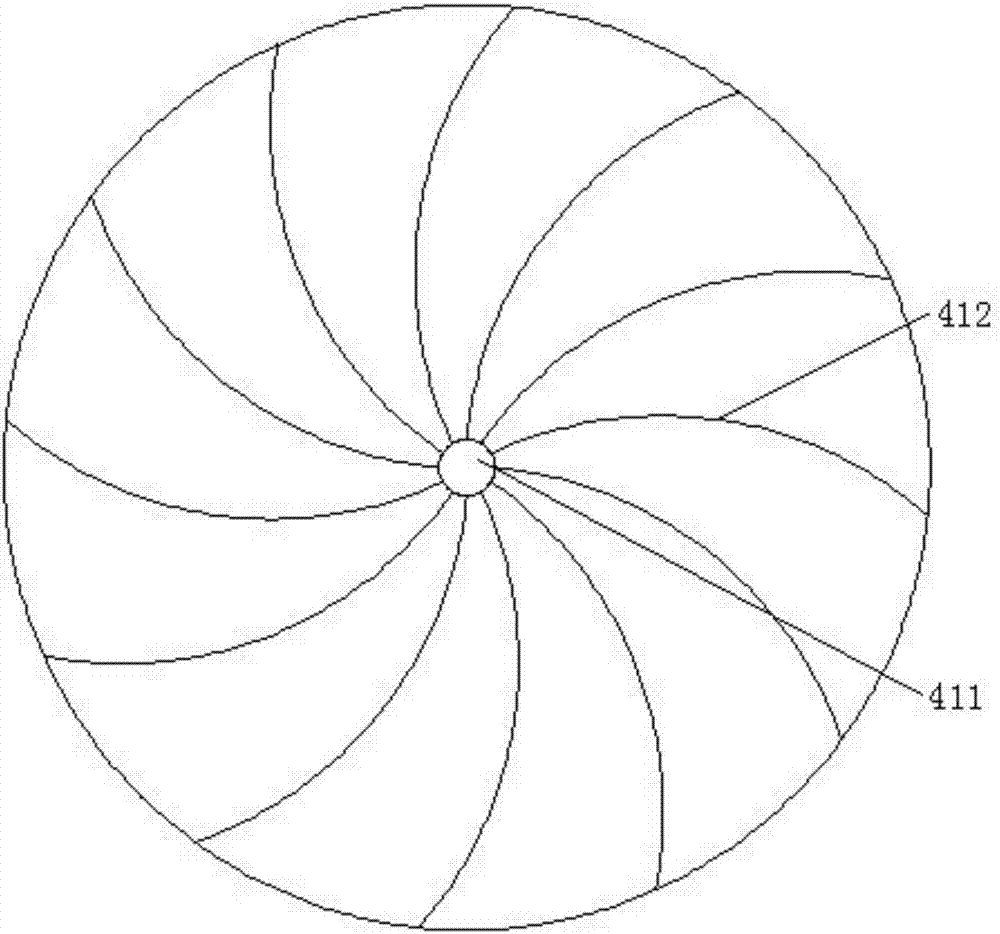

[0051] The above-mentioned dynamic physical aerosol separation system includes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com