A method to improve the performance of carbide-derived carbon supercapacitors

A carbide-derived carbon and supercapacitor technology, which is applied in the manufacture of hybrid/electric double-layer capacitors, etc., can solve the problems that restrict the development of supercapacitor electrode materials and the low specific capacitance value of carbide-derived carbon, and achieve excellent supercapacitor performance , good electric double layer characteristics, and the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

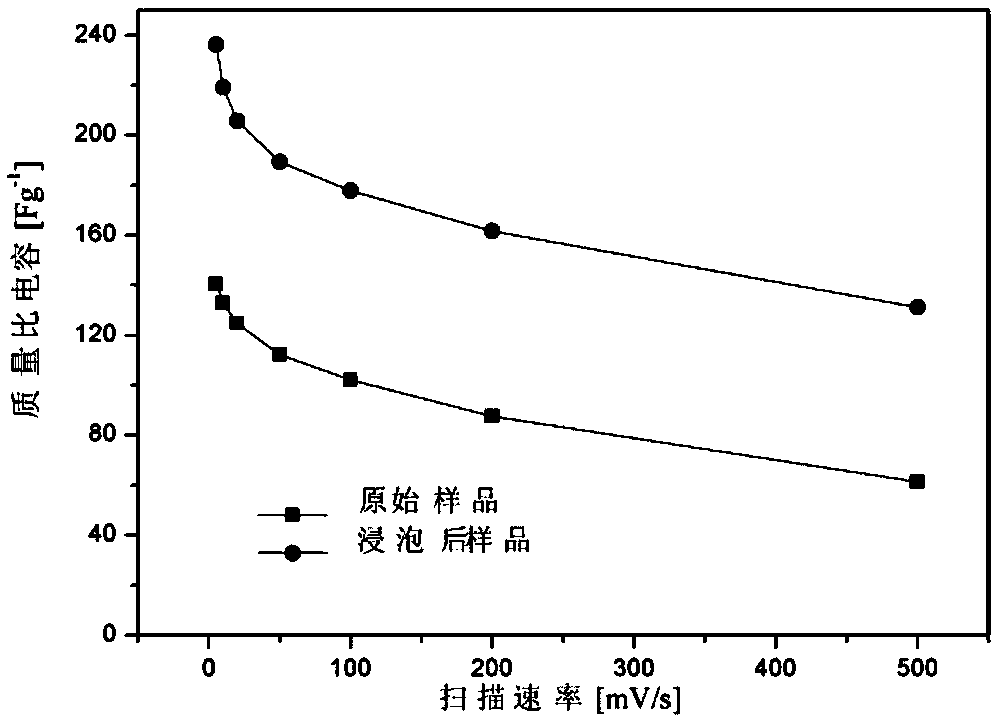

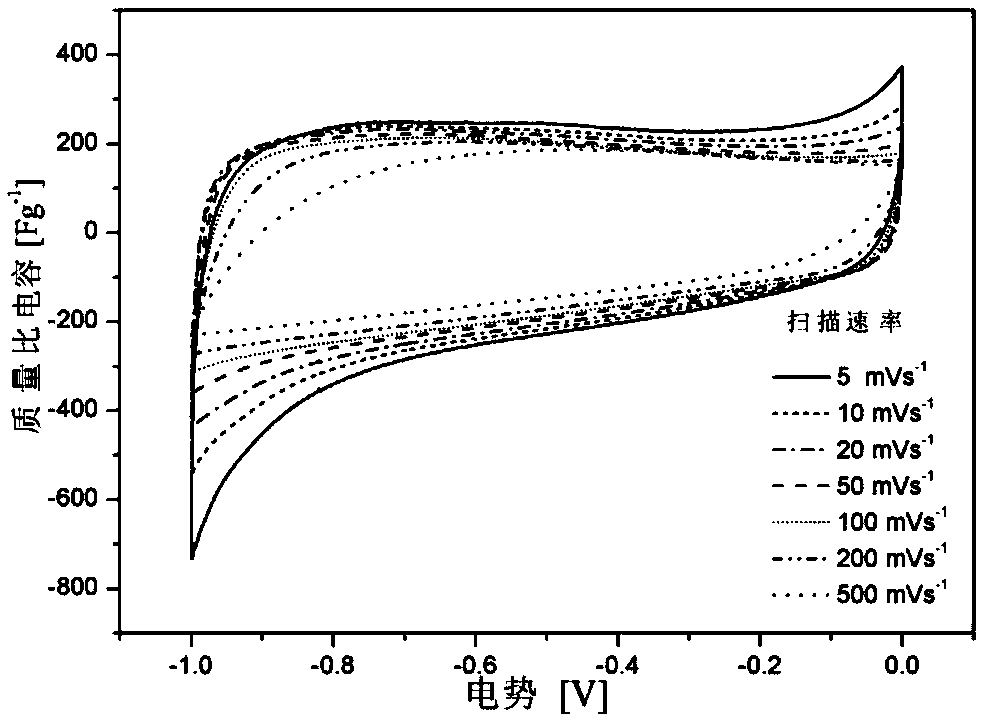

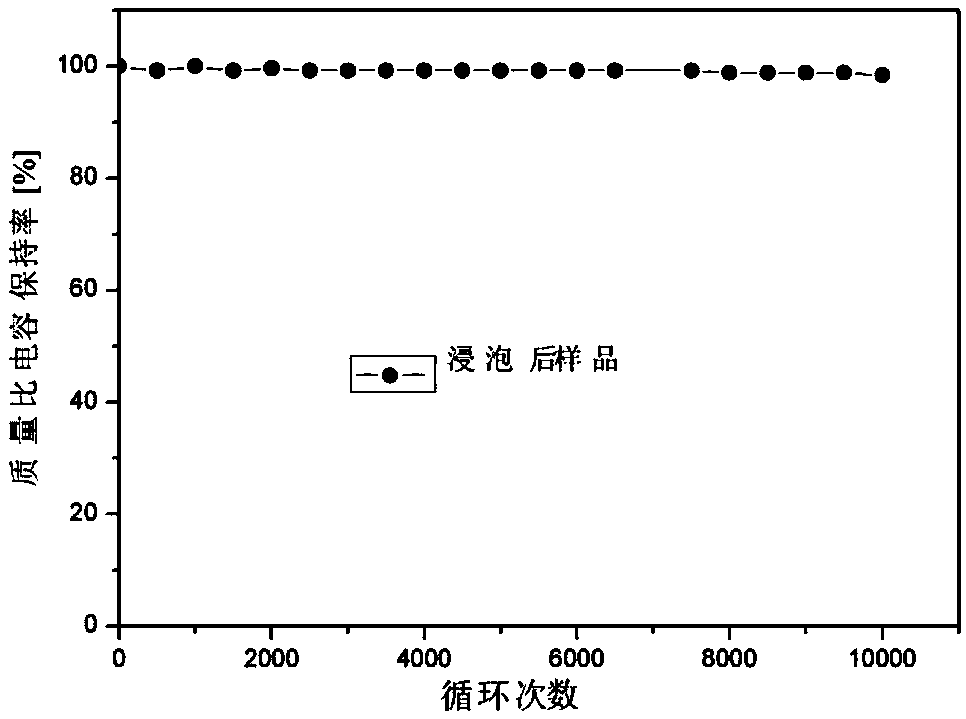

[0017] Using titanium carbide (TiC) with a particle size of about 2 μm as the reaction precursor, the high-temperature halogenation method was used to react with chlorine gas at 800 °C for 1 hour to obtain titanium carbide-derived carbon (TiC-CDC-800), and then the prepared The obtained TiC-CDC-800 was placed in the prepared HNO 3 and HF mixed acid solution In the process, after 1 hour of ultrasonic vibration, the TiC-CDC-800 and the prepared mixed acid solution were transferred together into a plastic test tube and the test tube mouth was sealed. The part of the test tube with mixed solution and TiC-CDC-800 sample is completely submerged, and after standing for 240 hours, wash the TiC-CDC-800 with deionized water until it is neutral, and dry it in a blast drying oven at 80°C , that is, the treatment of TiC-CDC-800 is completed.

[0018] The measurement of the specific capacity of the treated TiC-CDC-800: a conventional three-electrode system is used, the mercury oxide elec...

Embodiment 2

[0022] Titanium carbide (TiC) with a particle size of about 50nm was used as the reaction precursor, and titanium carbide-derived carbon (TiC-CDC-600) was obtained after reacting with chlorine gas at 600°C for 1 hour by high-temperature halogenation method. Then, the prepared TiC-CDC-600 was placed in the prepared HNO 3 and HF mixed acid solution After 1 hour of ultrasonic vibration, the TiC-CDC-600 and the prepared mixed acid solution were transferred into a plastic test tube and the test tube mouth was sealed. After that, the test tube was placed vertically in a constant temperature water bath at 25°C to make The part of the test tube with mixed solution and TiC-CDC-600 sample is completely submerged, and after standing for 192 hours, wash the TiC-CDC-600 with deionized water until it is neutral, and dry it in a blast drying oven at 80°C , that is, the treatment of TiC-CDC-600 is completed.

[0023] Measure by the method for embodiment 1, under 5mV / s scanning speed, the s...

Embodiment 3

[0025] Using silicon carbide (SiC) with a particle size of about 60nm as the reaction precursor, the high-temperature halogenation method was used to react with chlorine gas at 800°C for 1 hour to obtain silicon carbide-derived carbon (SiC-CDC-800), and then the prepared The obtained SiC-CDC-800 was placed in the prepared HNO 3 and HF mixed acid solution After ultrasonic vibration for 1 hour, transfer SiC-CDC-800 and the prepared mixed acid solution together into a plastic test tube and seal the test tube mouth. The part of the test tube with the mixed solution and SiC-CDC-800 sample is completely submerged. After standing for 264 hours, wash the SiC-CDC-800 with deionized water until neutral, and dry it in a blast drying oven at 80°C. , that is, the processing of SiC-CDC-800 is completed.

[0026] Measured according to the method of Example 1, at a scanning speed of 5mV / s, its specific capacitance value increased to 219F / g, while the specific capacitance value of untreated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com