Preparation method for GaN nanoparticles

A nanoparticle and roasting technology is applied in the field of preparation of gallium nitride nanoparticles, and achieves the effects of simple preparation process, strong operability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

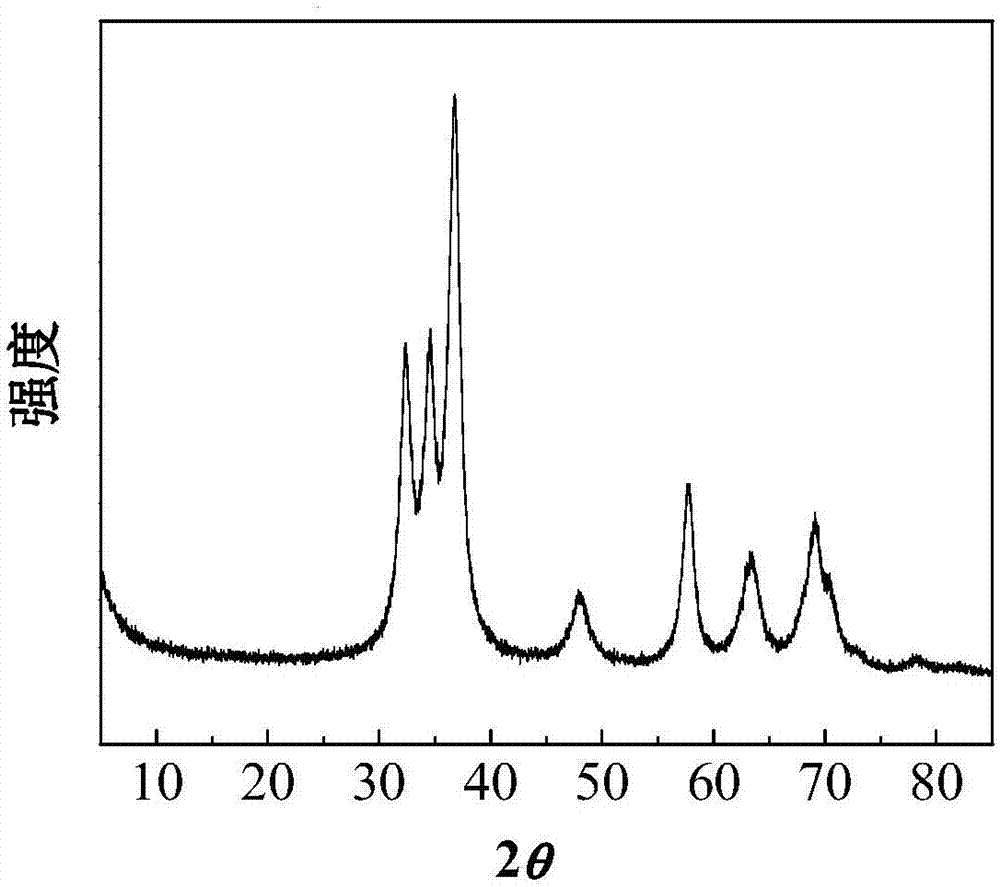

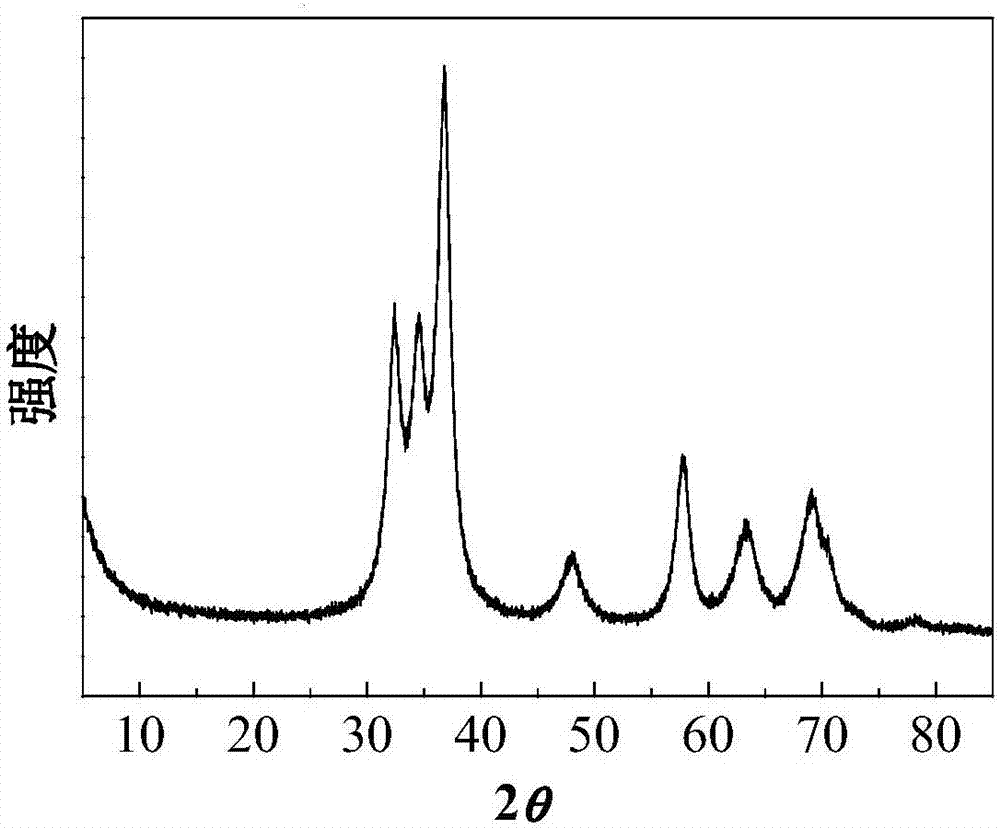

[0025] Grind 1g of gallium nitrate and 1g of melamine thoroughly and mix them evenly, put them into a porcelain boat, bake at 800°C for 1 hour in a nitrogen atmosphere, then lower the temperature to 550°C, stop nitrogen, bake at a constant temperature in an air atmosphere for 1 hour, and cool naturally to room temperature to obtain GaN nanoparticles.

Embodiment 2

[0027] Grind 1g of gallium nitrate and 2g of melamine thoroughly and mix them evenly, put them into a porcelain boat, bake at 800°C for 1 hour in a nitrogen atmosphere, then lower the temperature to 550°C, stop nitrogen, bake at a constant temperature in an air atmosphere for 1 hour, and cool naturally to room temperature to obtain GaN nanoparticles.

Embodiment 3

[0029] Grind 1g of gallium nitrate and 4g of melamine thoroughly and mix them evenly, put them into a porcelain boat, bake at 800°C for 1 hour in a nitrogen atmosphere, then lower the temperature to 600°C, stop nitrogen, bake at a constant temperature in an air atmosphere for 1 hour, and cool naturally to room temperature to obtain GaN nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com