Passivation Process of Nanoscale Damage Precursor on Fused Silica Surface

A fused silica, nano-scale technology, which is applied in the field of passivation technology of nano-scale damage precursors on the surface of fused silica, can solve the problems of destroying the surface shape of components, secondary pollution of component surfaces, threshold value increase, etc., to improve the surface quality of components, Effect of improving resistance to laser damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

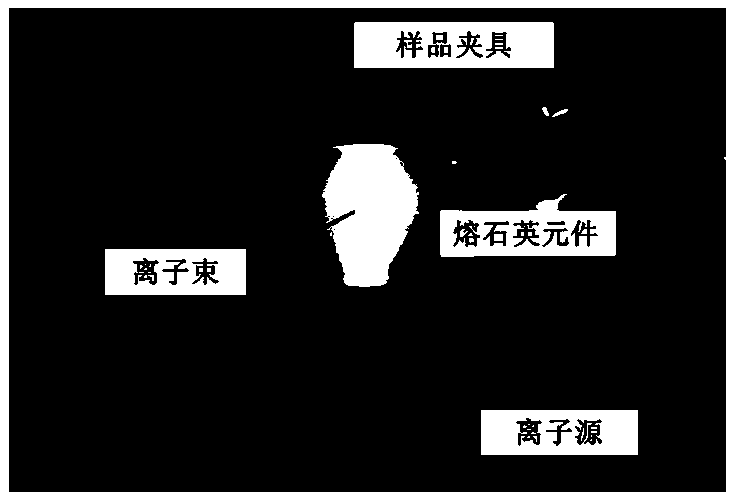

[0026]In this implementation, the plasma cleaning treatment and sub-plasma passivation treatment of the fused silica components are all carried out by the plasma polishing machine model KDIBF650L-VT developed by the National Defense Science and Technology University of the Chinese People's Liberation Army. The plasma polishing machine is aimed at advanced optical manufacturing. Developed by the Institute of Technology, it can realize the processing of ultra-high precision, space optics, and strong light optical components, and the surface roughness of the processed optical components can be controlled at the sub-nanometer level.

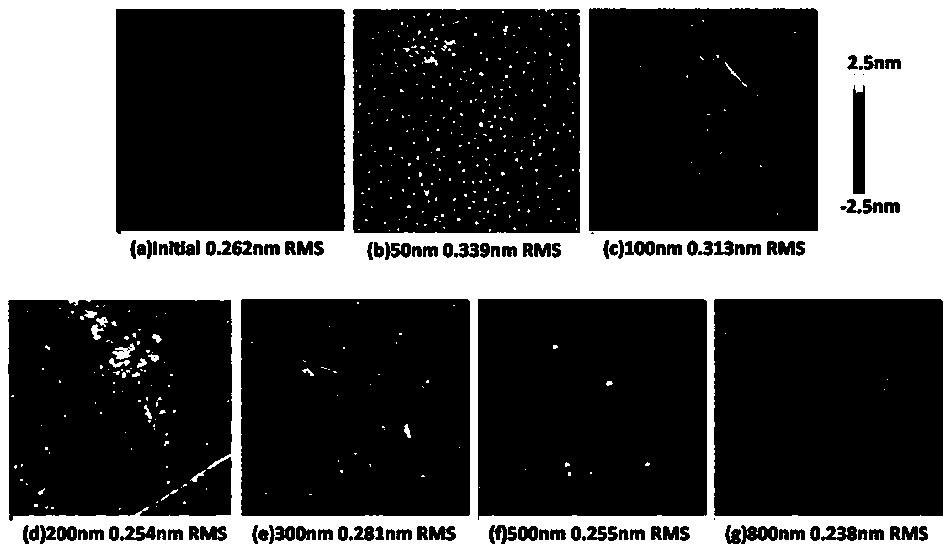

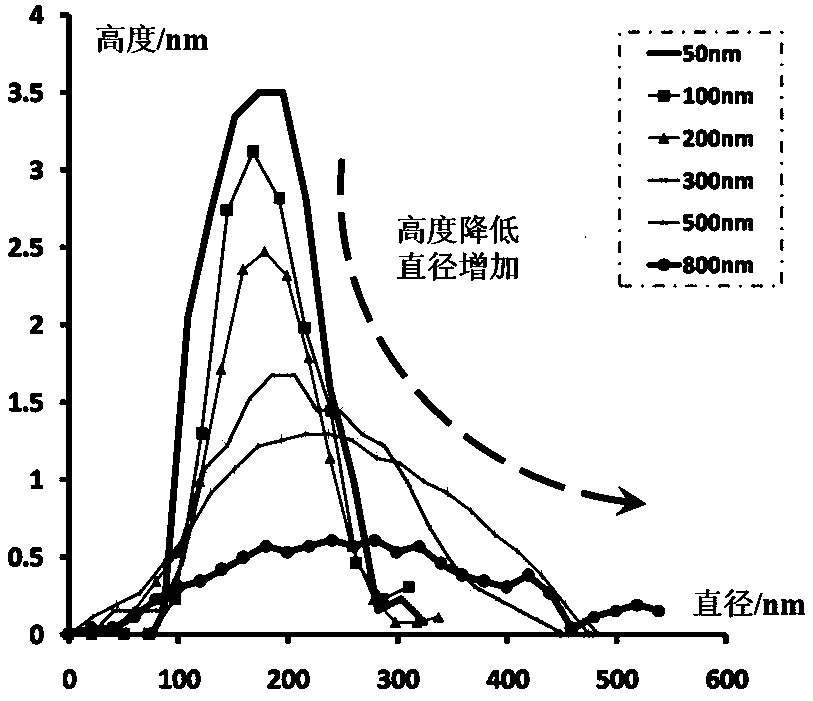

[0027] The processing object of this embodiment is a square fused silica element of 100mm × 100mm × 10mm. The pre-processing of the element is single-axis machine polishing. After polishing, there is no obvious scratch on the surface of the element, and the surface roughness Rq is 0.262nm. Carrying out the plasma passivation process of nanoscale damag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| optical damage threshold | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com