Crusher with water-jet cutter

A crusher and water jet technology, applied in grain processing and other directions, can solve the problems of the crusher blade slipping easily, affecting work efficiency, damaging the machine itself, etc., so as to avoid slippage and knife collapse, not easy to resonate, and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

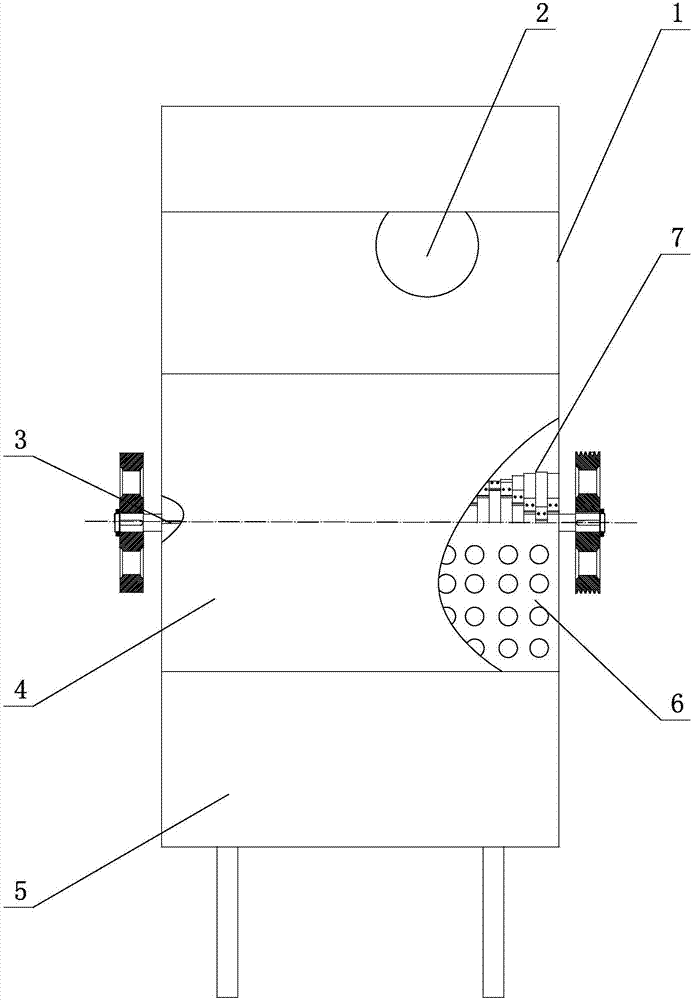

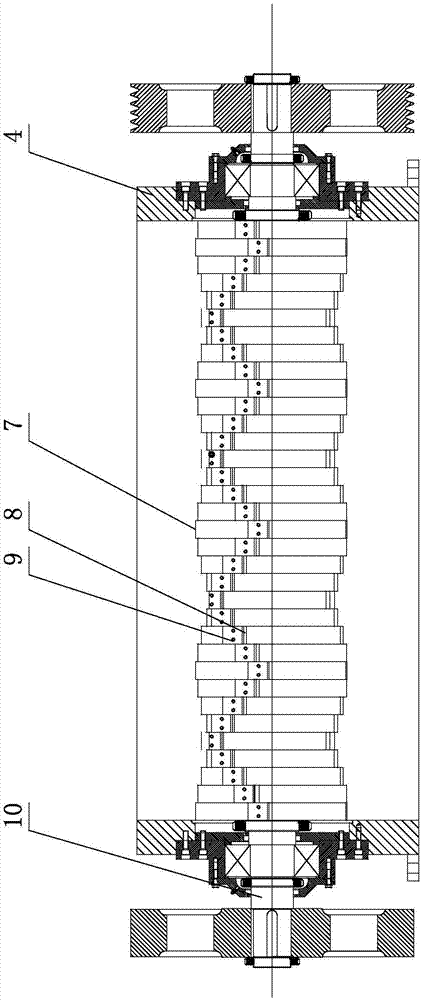

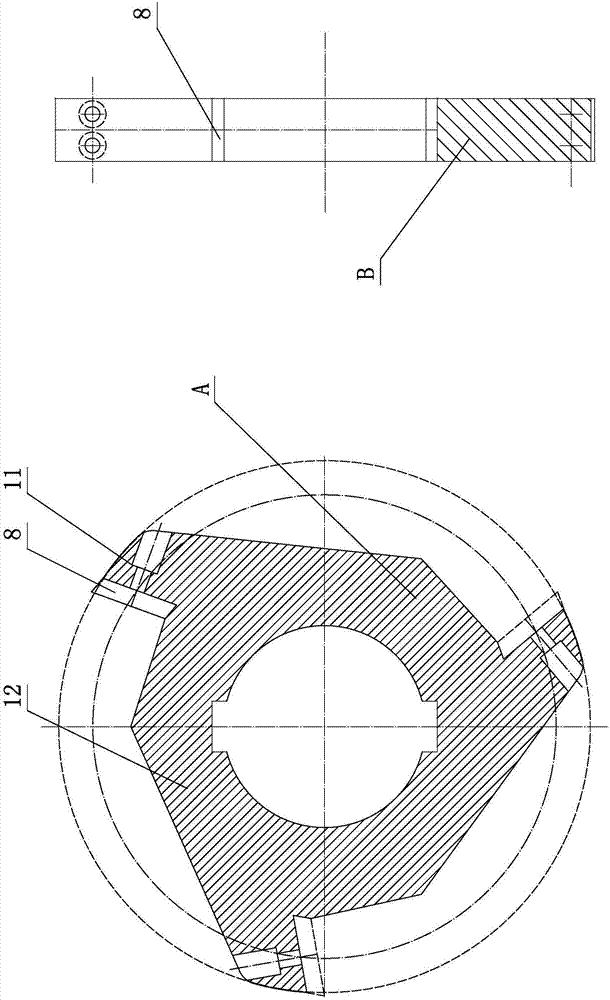

[0021] Such as Figure 1-Figure 5 , the water jet crusher of the present invention comprises a slurry box 4, a box cover 1 and a collection tank 5, the bottom of the slurry box 4 is provided with a collection channel 5, the top of the slurry box 4 is provided with a box cover 1, and the box cover 1 A feed port 2 is provided, and a collection tank 5 is provided with a discharge port; the slurry box 4 is provided with a main shaft 10, and a plurality of cutter groups are fixedly arranged on the main shaft 10, and each cutter group includes several cutter bodies 7, adjacent cutter bodies 7 dislocation arrangement, one end of the main shaft 10 is connected to the power output device; the inner wall of the slurry box 4 in front and rear of the main shaft 10 is provided with a fixed blade 3, and the fixed blade 3 cooperates with the cutter body 7.

[0022] In this embodiment: cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com